28

L510023-07

FUEL INLET RESTRICTION

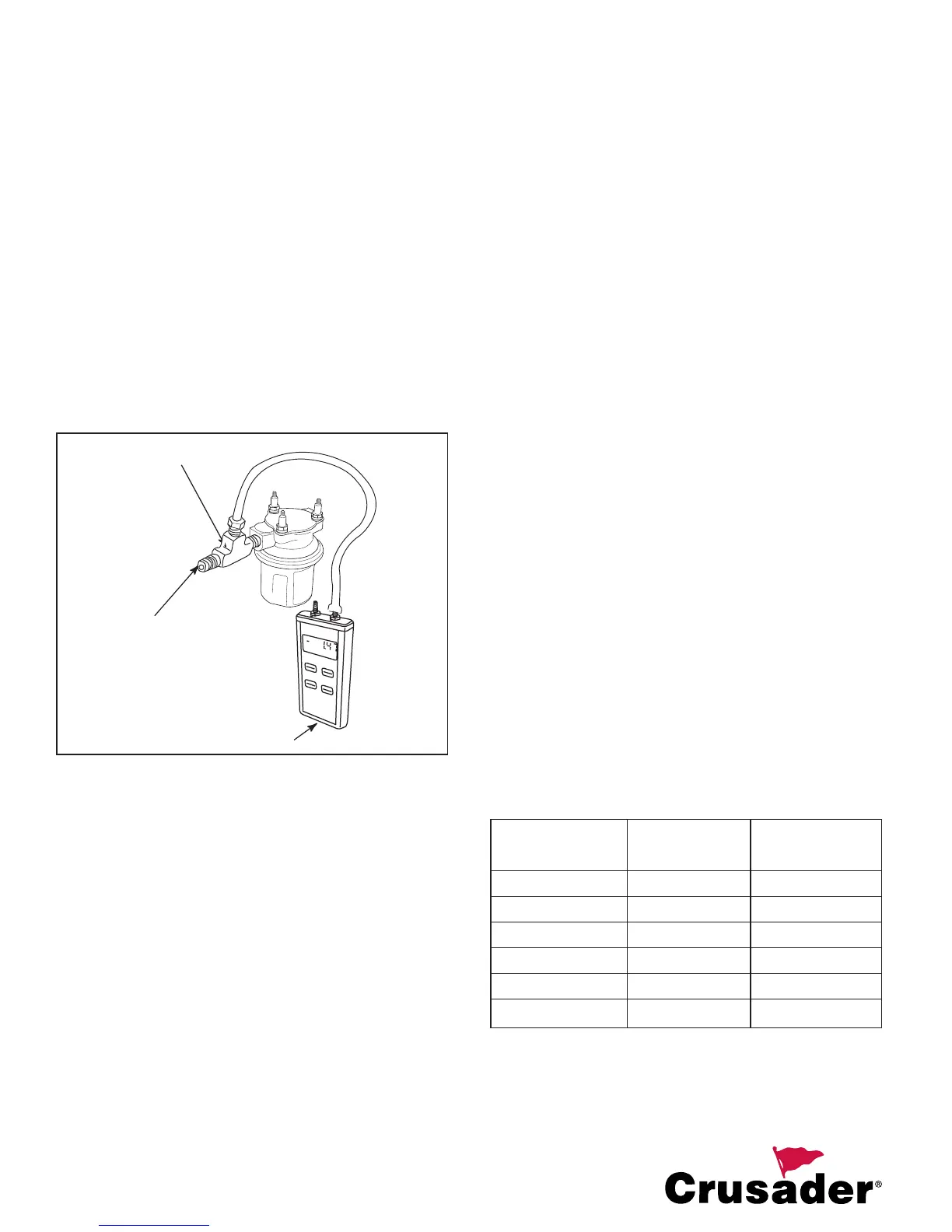

The maximum allowable inlet restriction at the electric

fuel pump inlet is 2 in. Hg (6.75 kPa) at 40 GPH (151

LPH) fl ow (typical idle fl ow rate). To test this, tee a

digital vacuum gauge into the fuel supply line at the

inlet to the low pressure fuel pump and read the gauge

at engine idle. If fuel inlet restriction exceeds the

maximum, the following is recommended:

A. Use supply side fuel lines including valves

and fi ttings with at least 1/2 in. (13 mm) I.D.

B. DO NOT install any additional fuel fi lters

between the fuel tank and the fuel pump inlet.

C. Avoid using crossover valves unless

absolutely necessary.

D. If an anti-siphon valve(s) is required, it is

recommended to use an electric solenoid

shut-off valve.

Figure 22 Checking Fuel Inlet Restriction

FUEL LINES

IMPORTANT: Current or proposed legislation may

require the use of low permeation fuel lines when

re-powering. This type fuel line will be marked with

the ‘Type A1-15’ designation. Check your local and

state regulations regarding the required use of this

type of fuel line.

IMPORTANT: Return fuel must fl ow back to the tank

from which it was drawn to prevent over-fi lling and

fuel spills through the vent system.

IMPORTANT: Prior to engine installation, fuel lines

should be inspected for compatibility with ethanol

blended fuel.

Replacement fuel line should be USCG Approved,

Marine Grade fuel line for use with ethanol blended

fuels.

Recommended minimum size fuel line:

• 1/2” (13 mm) I.D. supply side

• 3/8” (10 mm) I.D. return side. (If required.)

Fuel lines should be secured per ABYC

recommendations. In addition, the following steps

should be followed to minimize fuel temperature:

A. Route all fuel lines as low in the bilge as

possible to take advantage of the cooler ambient

temperatures found there.

B. Keep the use of brass fuel elbows and fi ttings

to an absolute minimum. Brass is a good

conductor of heat. Tests have shown that fuel

may begin to vaporize when passing through

a 90 degree brass elbow at only 85°F (29°C)

ambient temperature.

C. Maintain adequate engine compartment

ventilation.

IMPORTANT: The electric fuel pump on the engine

has been designed to function with a fuel/water

separator, with 10 micron fi lter capability and a

minimum of 90 gallons per hour fl ow rate, between

the pump and fuel source. Crusader DOES NOT

recommend the use of any additional fi lters installed

by the OEM or boat dealer. The use of additional

fi lters which do not meet the requirements stated

above, can cause one or more of the following:

• Fuel Vapor Locking

• Diffi cult Warm-Starting

• Poor Drivability

• Piston Detonation Due to Lean Fuel Mixture

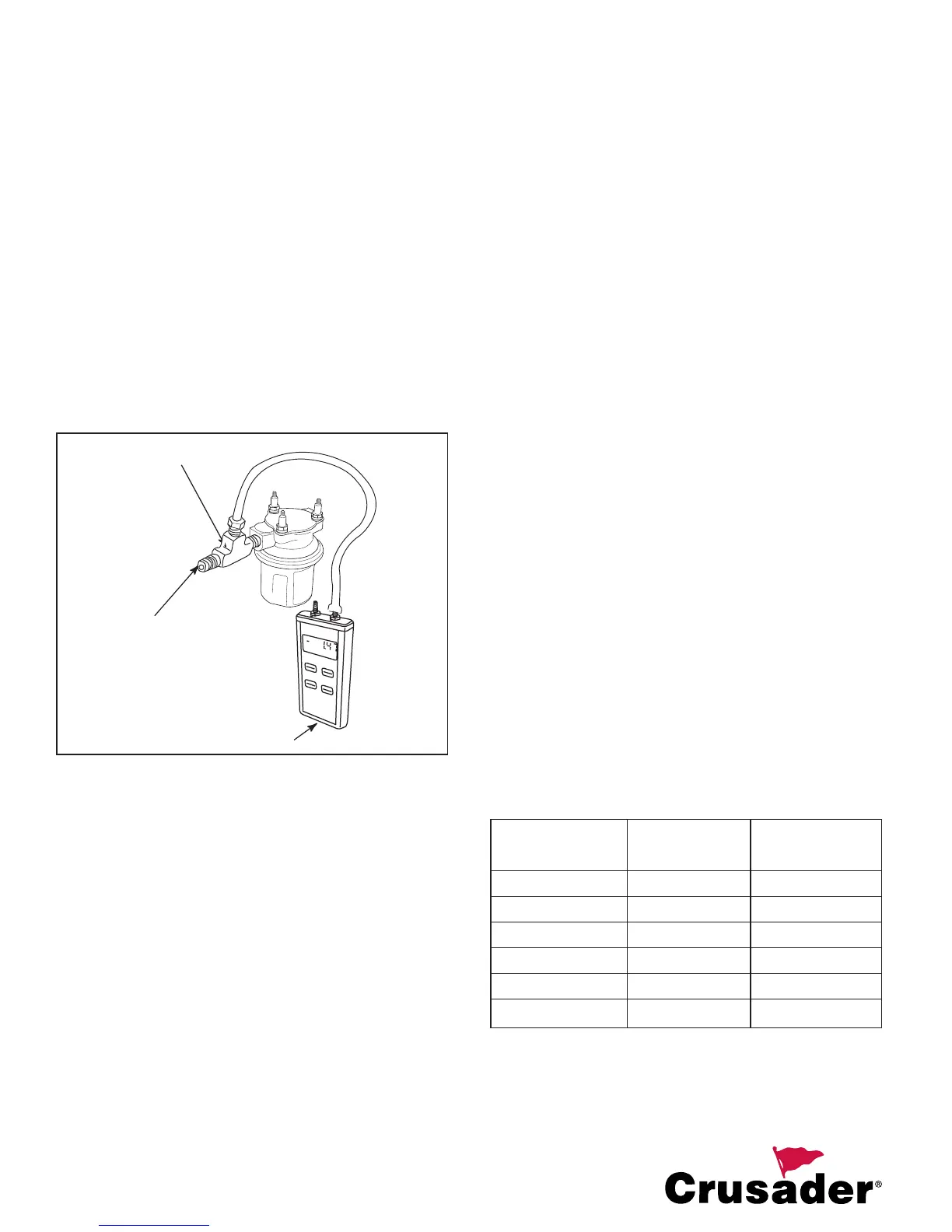

FUEL SYSTEM PRESSURE CHECK

Connect a fuel pressure tester to the test valve on the

fuel rail. Start and run the engine at idle and note the

fuel pressure reading. Verify reading meets or exceeds

minimum pressure (if shown) listed in the following chart.

IMPORTANT: Fuel pressure MUST be taken at wide-

open-throttle conditions in order to ensure that the

correct fuel pressure is present at all times.

See MASTER SPECIFICATIONS at the end of this

manual for specifi cations not shown on the chart.

Minimum WOT

Engine Pressure Pressure

MP 5.0L Master Specs. Master Specs.

MP 5.7L Master Specs. Master Specs.

MP 6.0L Master Specs. Master Specs.

MP 8.1L STD Master Specs. Master Specs.

MP 8.1L HO Master Specs. Master Specs.

Carb. 5.7L Master Specs. Master Specs.

O

N

Z

E

R

O

H

O

L

D

O

FF

S

T

O

R

E

M

E

M

O

R

Y

L

O

C

U

N

I

T

S

DI

G

I

T

A

L

-

M

A

N

OM

E

T

E

R

i

n

H

g

VACUUM GAUGE

FUEL INLET

TEE FITTING

Loading...

Loading...