36

L510023-07

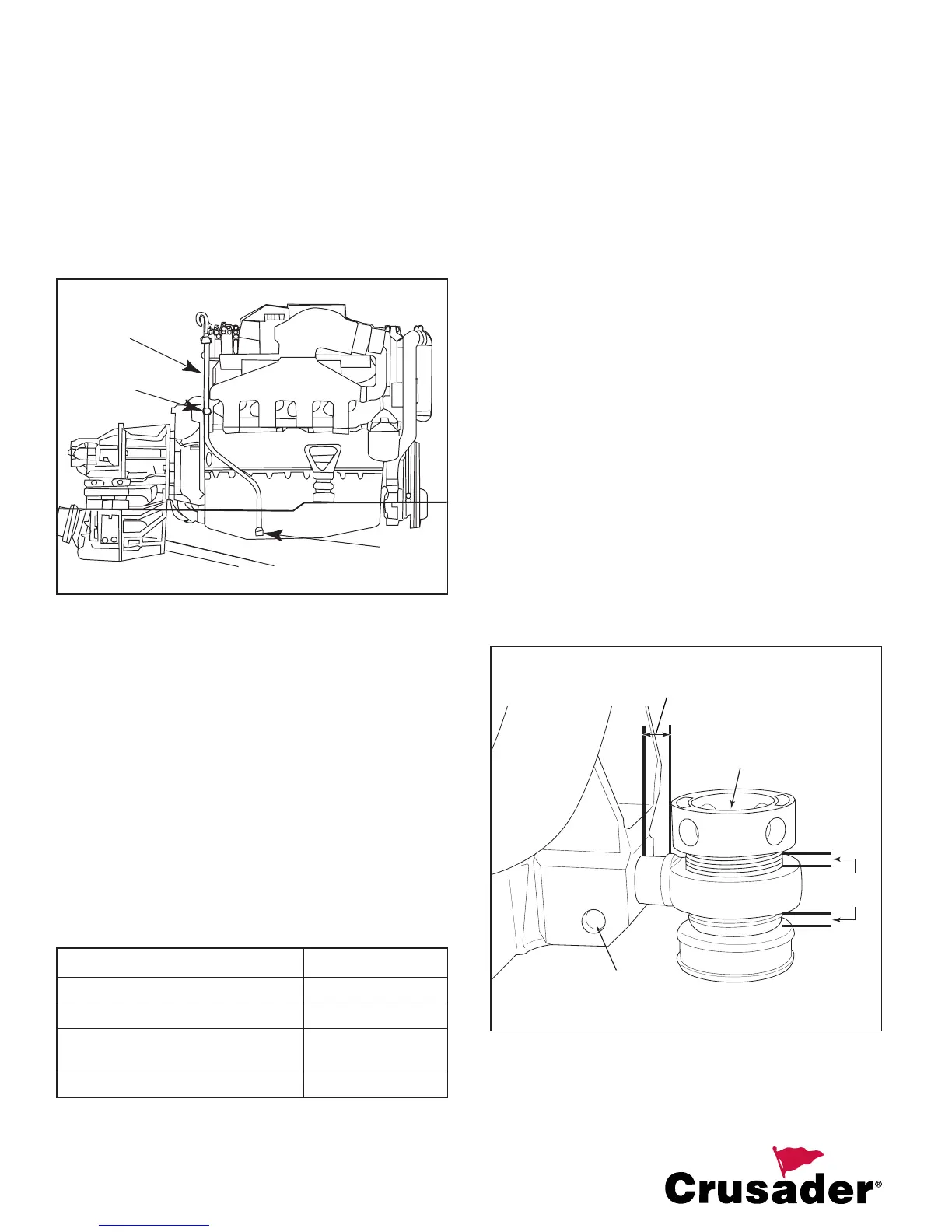

2. Remove the bolt retaining the dipstick mounting

clamp. Then, remove the dipstick fi tting at the

oil pan. Loosen the center bolt and rotate the oil

pan fi tting.

3. Put sealer on the dipstick fi tting threads and

reinstall into the oil pan fi tting. Mount and attach

the dipstick in the same manner as it was

removed from the other side.

4. Fill the engine with oil.

Figure 31 Oil Pan and Dipstick Fittings

Engines Equipped with Hurth and Velvet Drive

5000 Series Transmissions

Engine crankcase oil dipstick can be located either port

or starboard side of the engine, depending on installation

requirements. To move the dipstick, reverse the dipstick

and rubber caps on the dipstick tubes.

ENGINE INSTALLATION

NOTICE TO INSTALLER BEFORE STARTING

INSTALLATION: Read “General Information” and

“Installation Requirements” completely.

TORQUE SPECIFICATIONS

NOTICE: Tighten ALL fasteners (not listed) securely.

Engine Mount Attaching Bolts 45 lb-ft (61 N

.

m)

Fuel Line Inlet Fitting Securely

Trunnion Clamping Bolt and Nut 45 lb-ft (61 N

.

m)

Propeller Shaft Coupling Bolt and

Nut 50 lb-ft (68 N

.

m)

Exhaust Manifold Bolt 20 lb-ft (27 N

.

m)

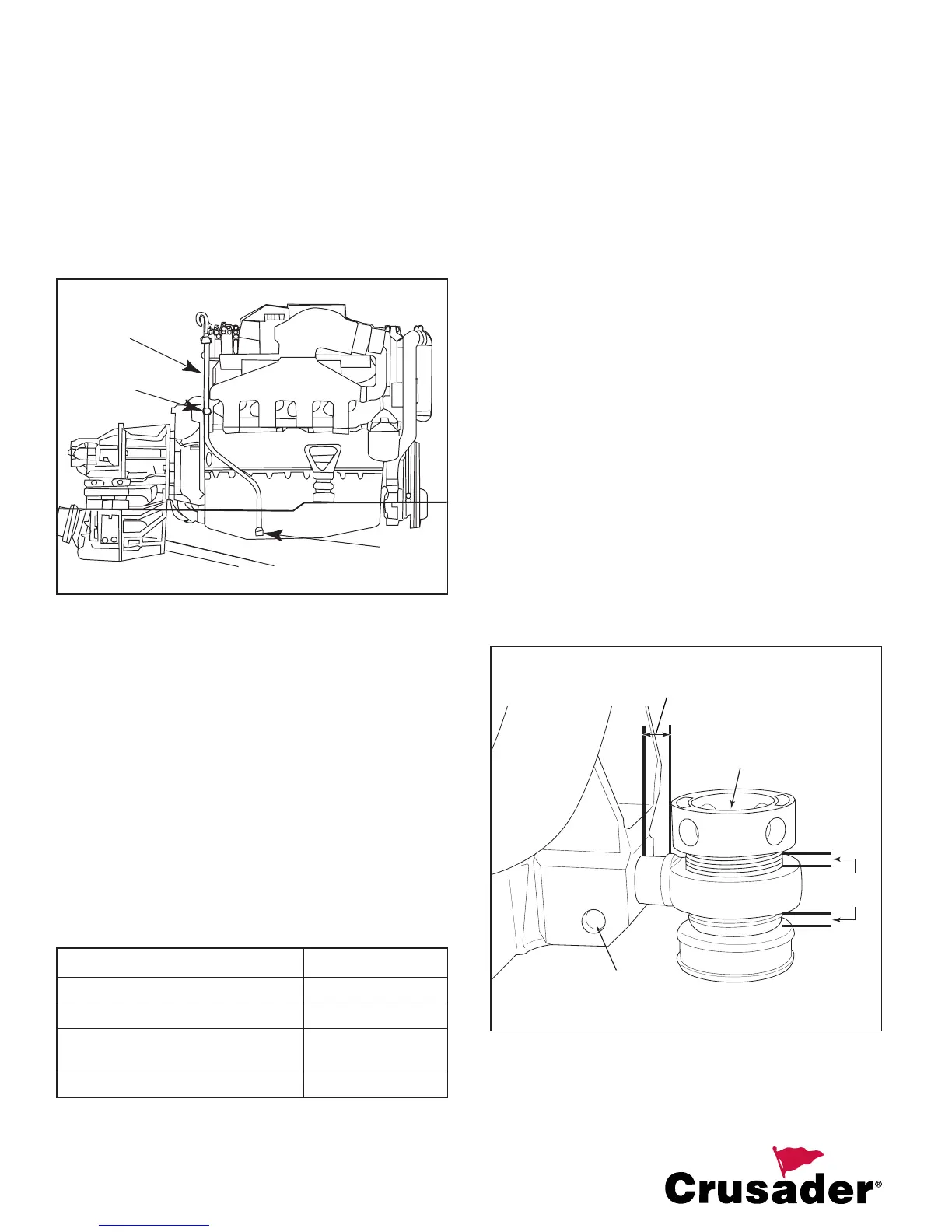

PRELIMINARY ENGINE ALIGNMENT

(Mount Adjustment Tool - P/N 22165)

1. Remove the lag screws holding the engine to

the shipping pallet. Attach a suitable sling to the

lifting eyes on the engine. Lift the engine from

the pallet with an overhead hoist.

2. Check the tightness of the engine mounts and

re-torque the mount attaching bolts to 45-50 lb-ft

(61-68 N

.

m), if necessary.

IMPORTANT: Engine mounts must be adjusted

as explained in Steps 3 and 4 to center mount

adjustment and establish a uniform height on all

mounts.

3. Check all four (4) engine mounts to ensure that

the distance from the bottom of the mount to

the bottom of the trunnion is as shown. If not,

turn the nylon adjusting sleeve in the direction

required to obtain the proper dimension.

4. Loosen the trunnion clamping bolt and nut on

all four (4) engine mount brackets to ensure the

following:

a. Large diameter of the mount trunnion is

extended as shown.

b. Each mount base is downward. Tighten the

trunnion clamping bolts and nuts slightly to

prevent moving in or out. Mounts must be

free to pivot when installing the engine.

Figure 32 Preliminary Engine Mount Extension

DIPSTICK

TUBE

CLAMP

OIL PAN

FITTING

TRUNNION

BOLT

0.5 in.

(12.5 mm)

3/8 in.

(9.5 mm)

LAG

BOLT

Loading...

Loading...