8.930-369.0 • 2848 • Rev. 4/13a

21

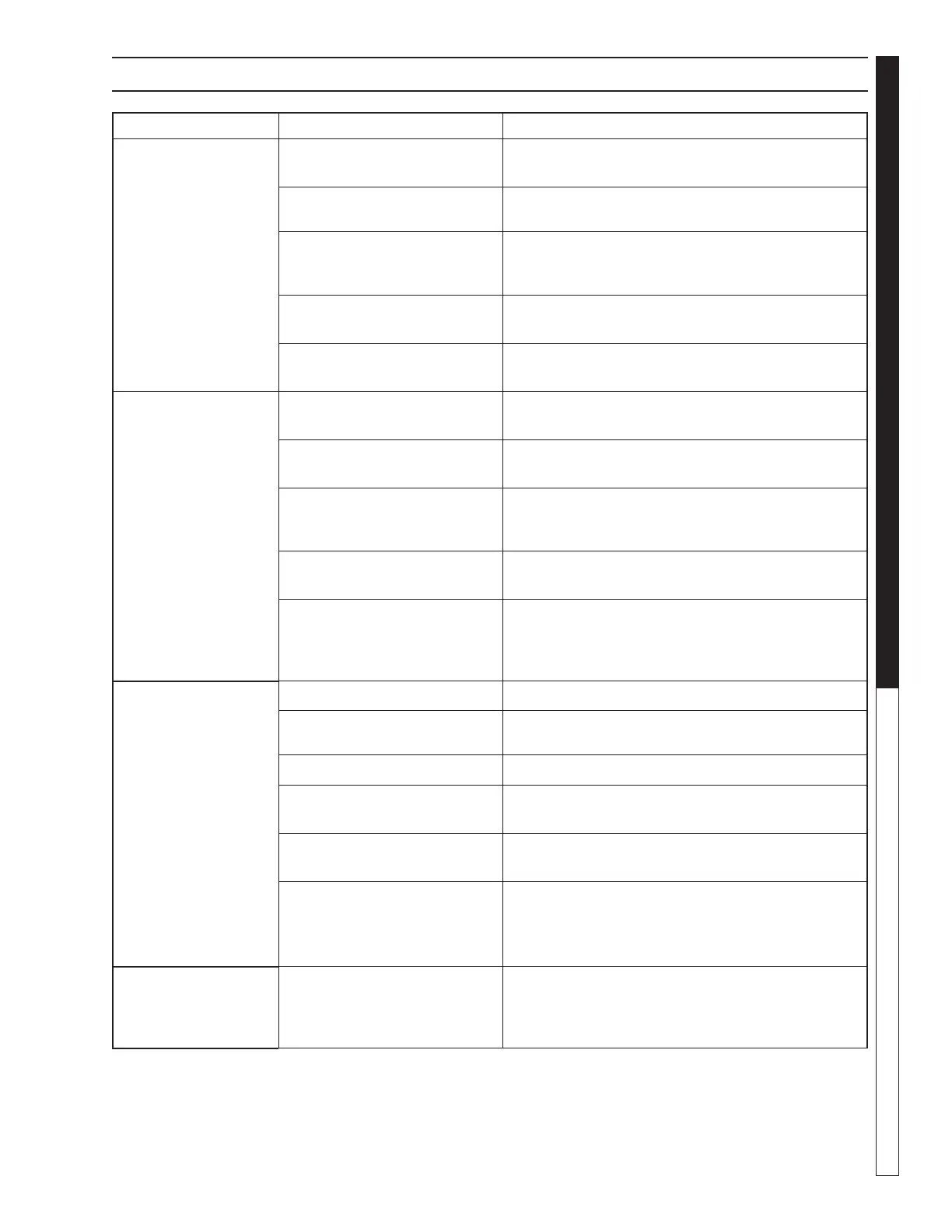

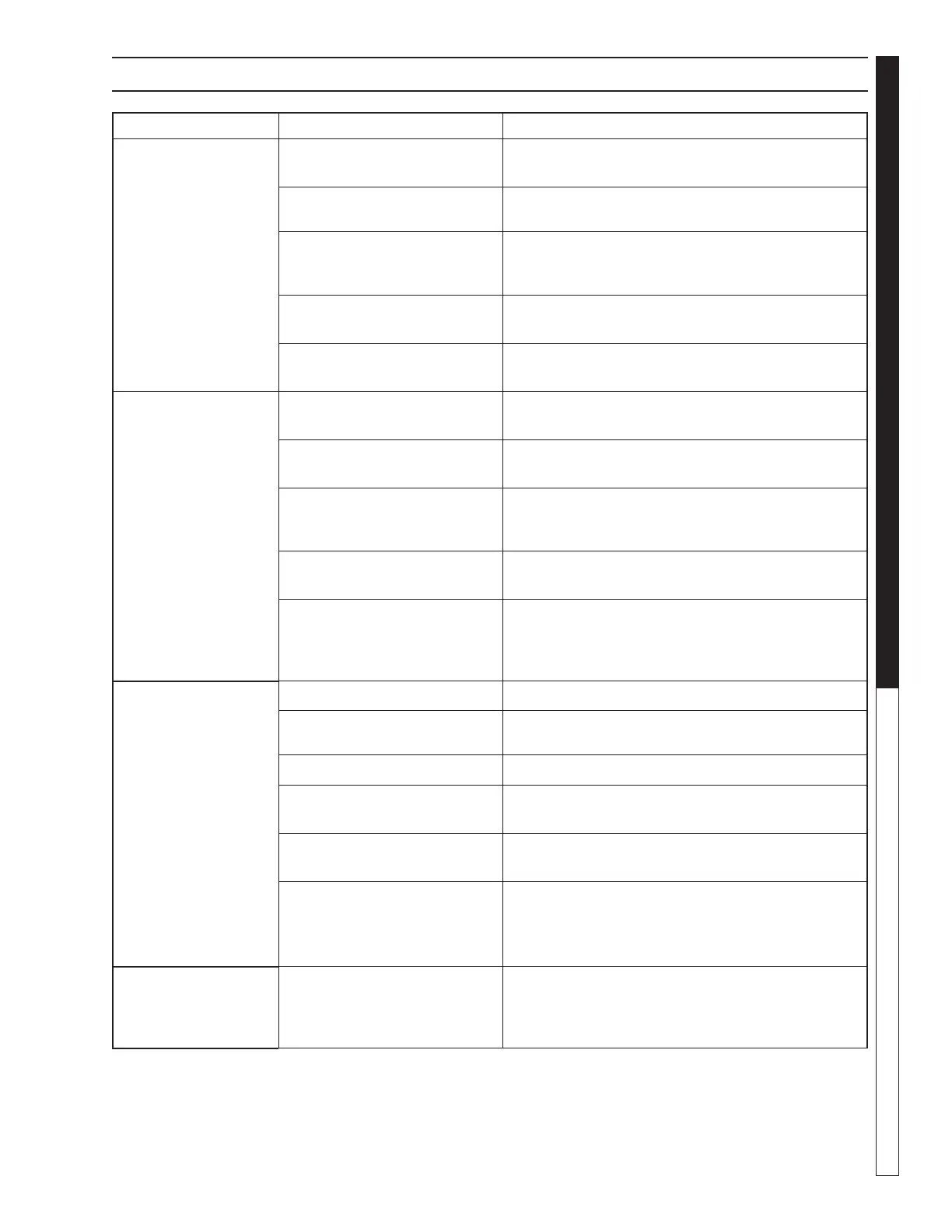

PARTS WASHER Troubleshooting Guide

SECTION 4: TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

MACHINE FAILS

TO START WHEN

“WASHING PARTS”

PROCEDURE IS

FOLLOWED

Main power disconnect is off

Verify that no service is being performed on the

machine, then turn the main power disconnect on.

Lid is not closing properly Check the lid closure safety

switch; adjust if necessary.

Failed lid closure safety switch Test the lid closure safety switch; replace

if necessary (See Adjusting the Lid Safety

Switch).

Failed washer cycle timer Test the wash cycle timer; replace

if necessary (See Lid Safety Switch).

Pump is not operating

properly

See Pump does not operate properly section.

TURNTABLE DOES

NOT OPERATE

PROPERLY

Parts are obstructing turntable

rotation

Check for parts obstructing rotation

of the turntable; rearrange if necessary.

Drive chain is not on the drive

pulley

Check drive chain; realign

on drive pulley if necessary.

Turntable motor compression

springs are not installed

Check the turntable motor compression

springs; install if necessary

(See Turntable Motor Assembly).

Blown fuse Check electrical panel for blown

fuse; replace if necessary.

Failed wash cycle timer Test the electrical panel to eliminate the

possibility of a blown fuse then contact

a licensed electrician or a service

representative to test the turntable motor.

PUMP DOES

NOT OPERATE

PROPERLY

Low water level in sump Check sump water level; add water if necessary.

Pump intake is plugged Check pump intake for obstructions; clean out if

necessary.

Pump overload relay is tripped Reset the motor overload relay.

Blown fuse Check electrical panel for a

blown fuse; replace if necessary.

Line voltage is too low Contact a licensed electrician to verify

that the line voltage is between 208V and 240V.

Pump is failed Test the electrical panel to eliminate the

possibility of a blown fuse then contact a

licensed electrician or a customer service

representative to test the pump motor.

OIL SKIMMER

DOES NOT

OPERATE

PROPERLY

Blown fuse Check electrical panel for a blown fuse; replace if

necessary.

Loading...

Loading...