8.930-369.0 • 2848 • Rev. 4/13a

PARTS WASHER Maintenance Guide

26

SECTION 5: MAINTENANCE AND REPAIR

MAINTAINING THE MACHINE

To ensure optimum performance and trouble-free

operation, observe the following maintenance schedule

consistently.

Daily Maintenance

• Checkthewaterlevel;addwaterifnecessary.

• Cleanthedebrisscreen.

• Removeoilfromthewashsolutionusingtheoil

skimmer system (See Using the Oil Skimmer

System).

Weekly Maintenance

• Examine the spray nozzles;clean and alignif

necessary (See Cleaning and Aligning the

Spray Nozzles).

• Wipe down the exterior of the machine using

degreaser spray and a soft, damp cloth. TO

PREVENT ELECTRICAL COMPONENT FAIL-

URE, DO NOT SPRAY THE MACHINE WITH

WATER.

• Detergent Concentration Level: Check deter-

gent level weekly to maintain concentration level

which decreases when water is added. The pH

level of this detergent must be in accordance with

the detergent manufacturer's recommendation.

NOTE: Degreaser spray and a damp cloth will usu-

ally remove all dirt and grime from the machine. For

particularly stubborn soap deposits, use a soft cloth

dampened with warm solution from the wash chamber.

Monthly Maintenance

• Cleanoutthesumpchamberanddetailsump

(See Cleaning out the Sump).

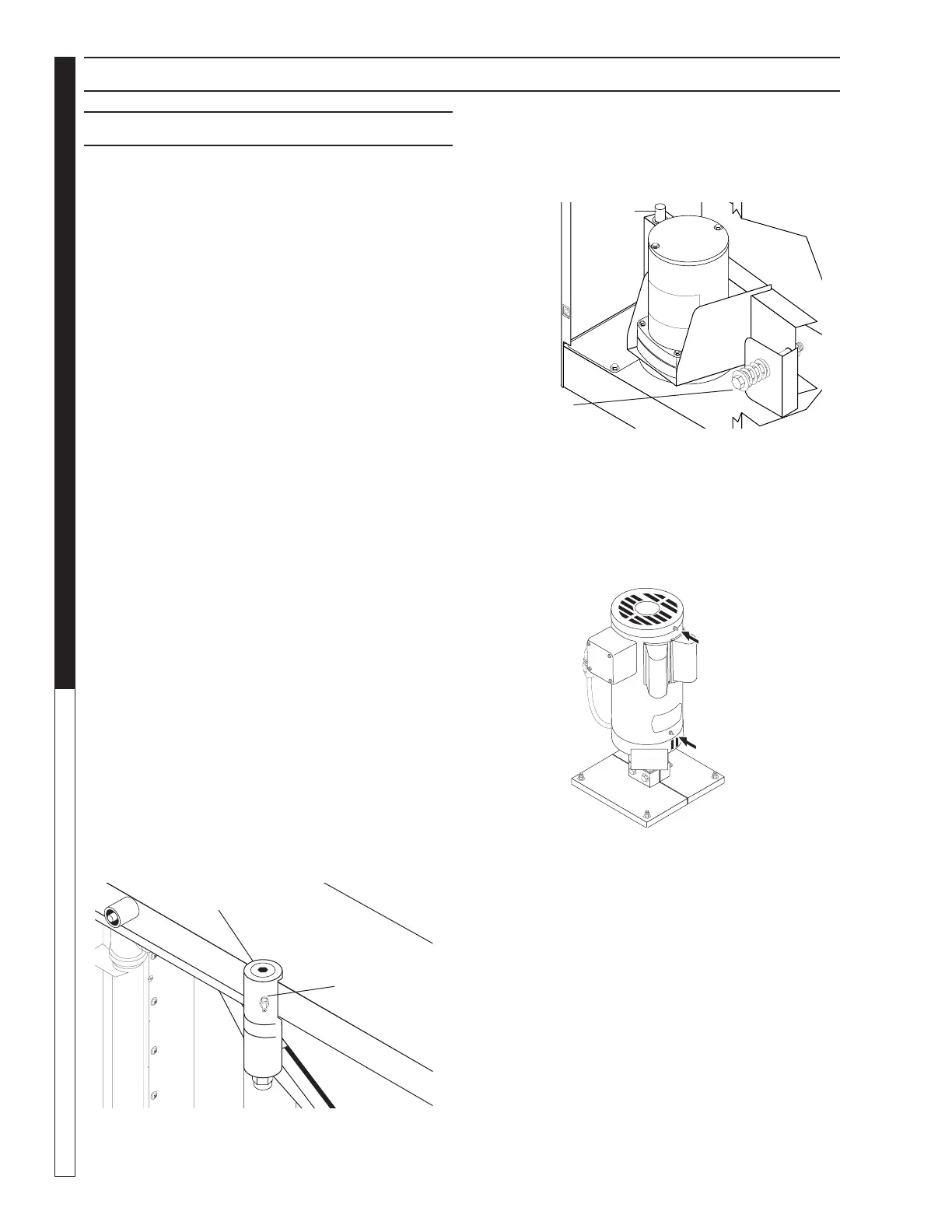

• Lubricate the door spindle using high-quality

automotive grease. Add grease until it begins to

flow out of the joint beneath the grease fitting,

then wipe excess grease from the fitting and the

joint (See figure below).

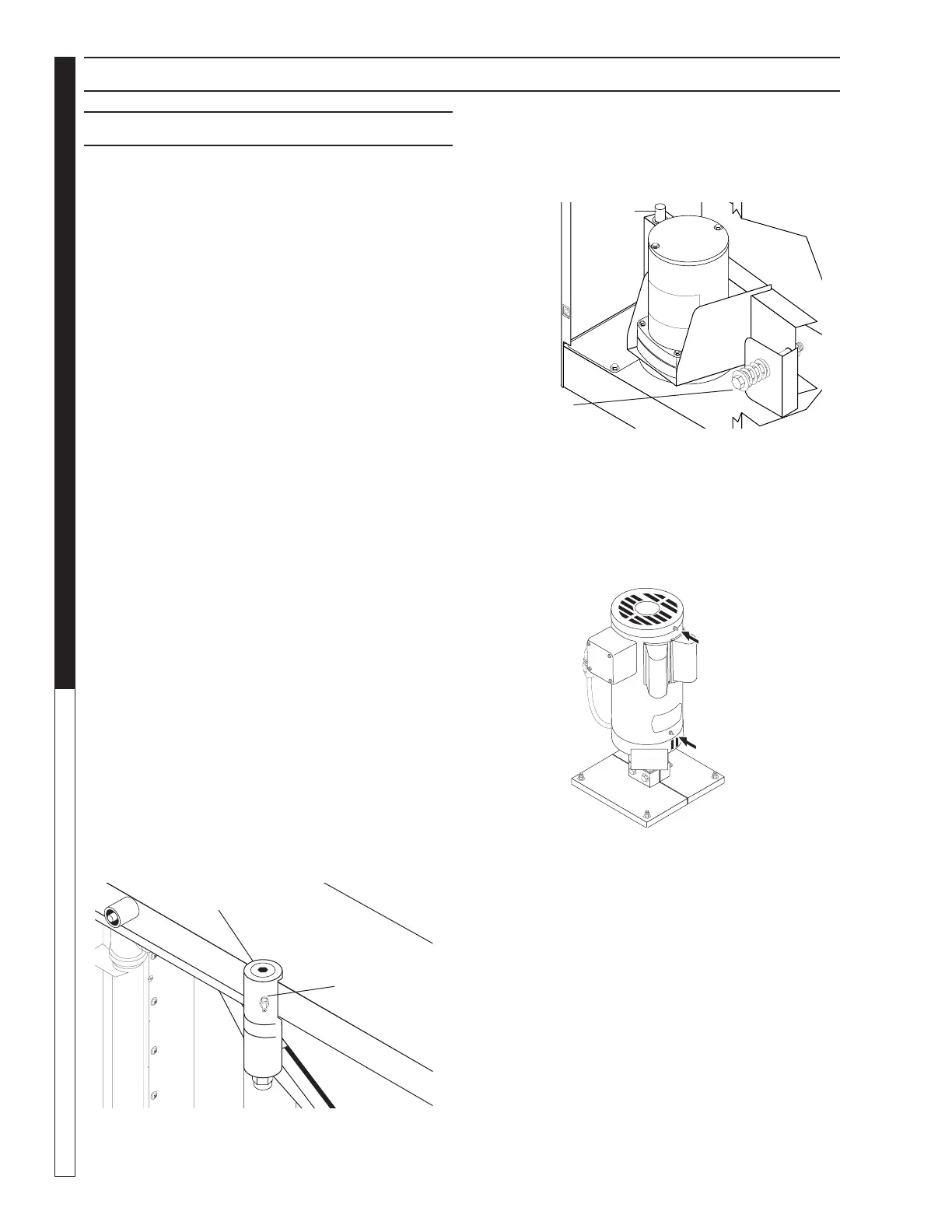

Semi-Annual Maintenance

• Lubricate the pivot pin on the turntable

motor assembly with machine oil or anti-seize

(See Figure Below).

• Lubricatetheupperandlowerpumpbearingsus-

ing high-quality automotive grease (See Figure

Below). Do not over grease the bearings; over

greasing could cause premature failure.

For 5HP pumps, add 1–2 strokes of grease every

six months; for pumps larger than 5HP, add 2–3

strokes of grease every six months.

Cleaning and Aligning the Spray Nozzles

To ensure optimum cleaning performance, it is important

that you examine the spray nozzles periodically and

clean and align them if necessary.

To clean a plugged nozzle, remove it from the spray

pipe and use a small wire brush to free the nozzle of

any obstructions. When you replace the nozzle on the

spray pipe, make sure you align it according to the

figure on top of the following page to maintain a proper

spray pattern.

NOTE: The spray nozzles are sized and positioned

to optimize the distribution of cleaning solution in

the wash chamber. If you remove the nozzles make

sure you replace them in the correct position on the

appropriate pipe.

Door Spindle

Grease Fitting

Pivot Pin

Compression

Spring Assy.

Grease

Fitting

Grease

Fitting

Loading...

Loading...