8.930-369.0 • 2848 • Rev. 4/13a

27

PARTS WASHER Maintenance Guide

SECTION 5: MAINTENANCE AND REPAIR

Using the Oil Skimmer System

The oil skimmer system is most effective if used when

the cleaning solution in the sump is cool.

The frequency at which you must remove the oil from

the wash solution will depend on machine usage. Under

typical operating conditions you may need to remove

the oil every day.

IMPORTANT: The skimmer motor is equipped with a

thermal overload switch which protects the skimmer

from overheating. If you attempt to use the oil skimmer

system when the wash solution is hot, the thermal

overload will probably trip and the motor will shut off

until it cools. Under normal skimming conditions (when

the wash solution is cool) the thermal overload should

not trip.

To remove oil from the cleaning solution, perform the

following procedure:

Step 1:

Allow the machine to sit idle for at least 30 minutes to al-

low the oil to float to the surface of the wash solution.

Step 2:

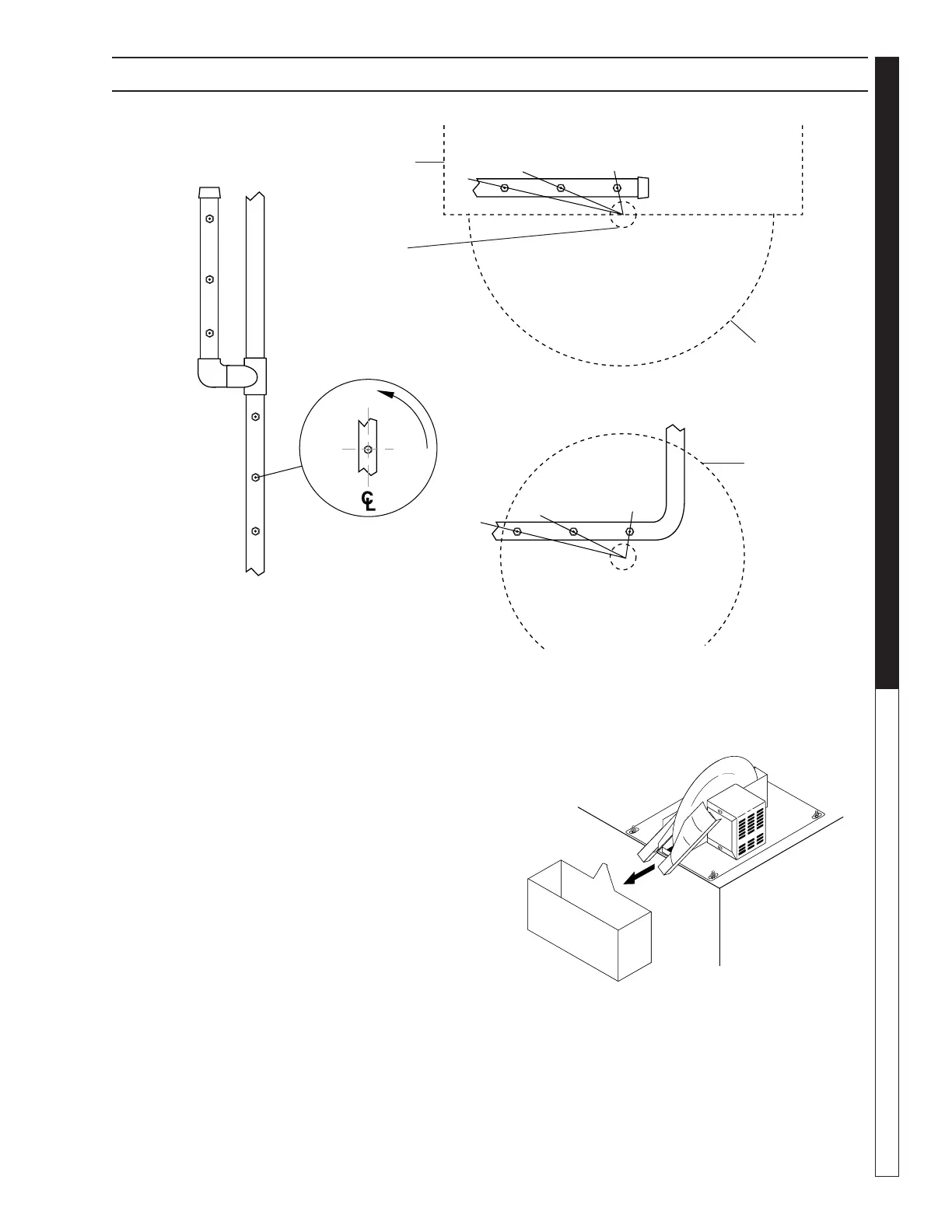

Ensure that the oil collection container is in place (See

figure below), then turn the skimmer switch to the “ON”

position.

Step 3:

Allow the oil skimmer to operate until it is no longer

extracting oil from the cleaning solution.

TIP: While extracting oil from the cleaning solution,

oil will flow off the wiper blades in a fine continuous

stream. Water will flow off the blades in droplets. Once

droplets begin to flow off the wiper blades, stop the

skimmer motor.

Optional Oil

Container

Oil Skimmer

Assy.

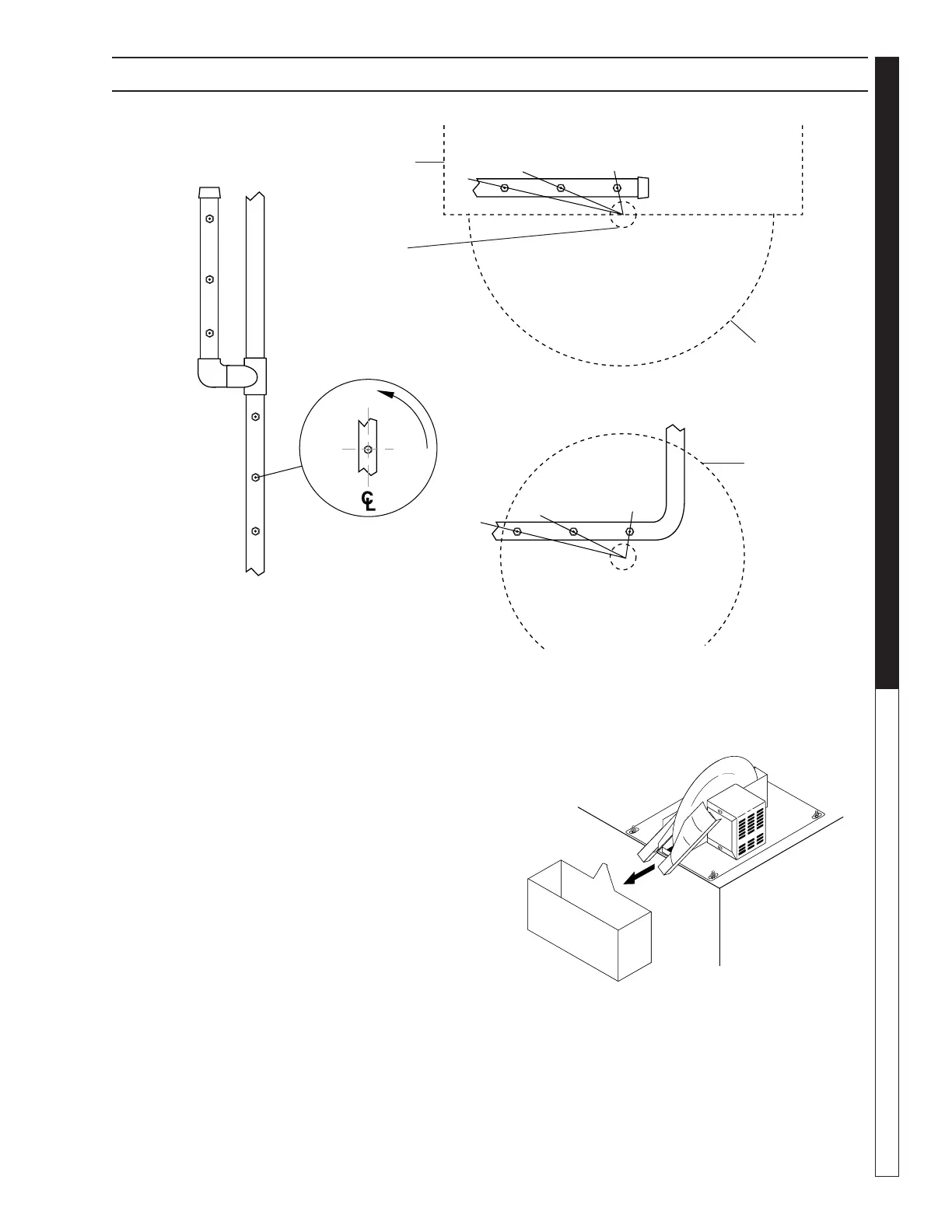

Align the notch in each

spray nozzle with the

center of the turntable.

Rotate each nozzle

approximately 3° from the

centerline of the pipe.

BOTTOM NOZZLES

SIDE NOZZLES

TOP NOZZLES

3°

Turntable

Door

Cabinet

Pivot

Assy.

Align the notch in each

spray nozzle with the

center of the door pivot

assembly.

Loading...

Loading...