8.930-369.0 • 2848 • Rev. 4/13a

PARTS WASHER Troubleshooting Guide

22

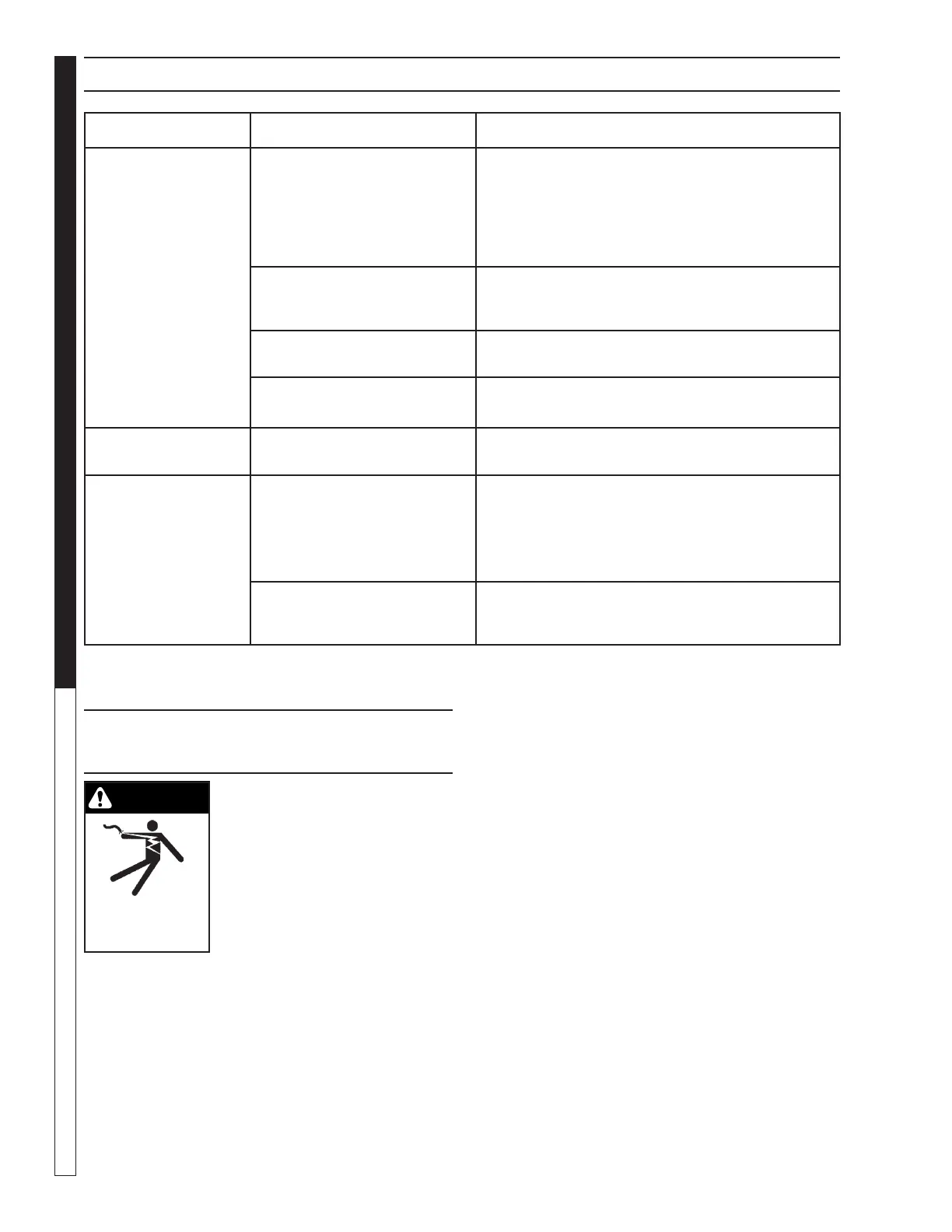

SECTION 4: TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

OIL SKIMMER

DOES NOT

OPERATE

PROPERLY

(CONTINUED)

Skimmer blades are too tight Turn on the skimmer motor and observe the

contact between the skimmer blades and the

skimmer disk. If the blades skip, bind, or leave

a significant scratch on the disk, they are

too tight. To loosen the blades, gently

bend them away from the skimmer disk.

Cooling fan on skimmer

motor is jammed

Turn off power to machine, remove

skimmer motor housing, ensure that

cooling fan is free of obstructions.

Failed skimmer timer Test the skimmer timer; replace if necessary (See

Wash Cycle, Heater, and Skimmer Timers).

Failed skimmer motor Contact a licensed electrician to test

the motor; replace if necessary.

LID LEAKS

Lid closure safety switch

is not adjusted properly

Check the lid closure safety

switch; adjust if necessary.

INTERIOR

OF MACHINE

IS RUSTING

Low detergent concentration

or improper detergent

usage

Our detergents, when used at proper

concentrations of 10 to 12 scoops (20 to 24 cups)

per 50 gallons of water, contains adequate rust

inhibitors to prevent rust. Verify that you are

using our detergents at the correct concentration.

Condensation on door and

cabinet causing rust during

idle periods

Leave door open.

TROUBLESHOOTING THE

ELECTRICAL SYSTEM

To troubleshoot the electrical sys-

tem use the following diagrams to

eliminate the possibility of a blown

fuse or a bad connection, then refer

to Testing Individual Components

to determine which component is

causing the problem.

WARNING: Electrical shock

could cause serious injury or

death.

• Electricaltroubleshootingshouldbeperformed

by qualified personnel only.

• Avoidcontactwithpowerleads,terminalsand

fuses when power is connected.

• Disconnectpowertomachinebeforeremoving

fuses or other electrical components.

KEEP WATER SPRAY

AWAY FROM

ELECTRICAL WIRING.

Loading...

Loading...