Return to TOC Curtis 1239E-1269E Manual, os 37.0 RevA – May 2021

10 — VEHICLE CONTROL LANGUAGE (VCL)

pg. 113

Aer the “Brake Type = 5” switch, the brake signal passes through a limiter which limits the brake

signal to a range of 0–100% (0–32767). Aer the limiter the brake signal is a VCL variable called

Mapped_Brake, which is displayed as Mapped Brake in the Monitor » Inputs menu. Checking the

value of Mapped_Brake using the 1313 is a good way to see if the Brake Menu parameters are set

correctly. A VCL program can control the brake by changing the variable VCL_Brake (only if Brake

Type = 5).

The brake signal then goes through a selector which will change it to 100% if the fault-action

FullBrake is active. (see Troubleshooting Chart).

e brake signal then goes through a third selector switch that will set the brake signal = 0% if the

Brake Pedal Enable parameter is set O. If set On, then the brake signal will pass through to the

Control Mode Processing block. e brake signal aer this third selector switch is the VCL variable

called Brake_Command and Brake Command in the Monitor » Inputs menu.

Brake_Command is the nal value of the brake signal chain that is input to the Control Mode

Processing block; see Figure 19. Checking the value of Brake_Command using the 1313 is a good

way to see the nal brake signal. Note: If Brake_Command is non-zero in Speed Mode Express or

Speed Mode, the rottle_Command will be set to 0% (see Fig. 19).

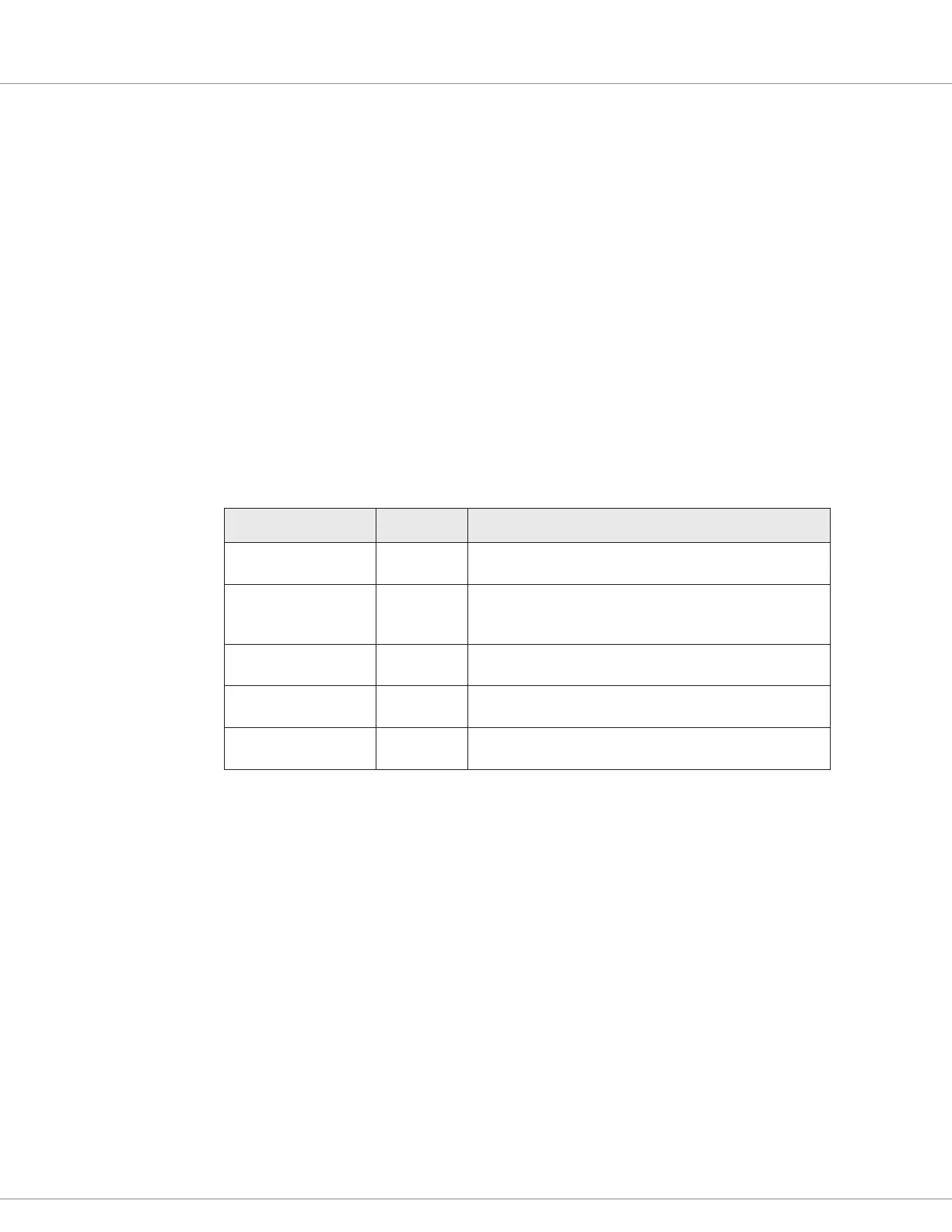

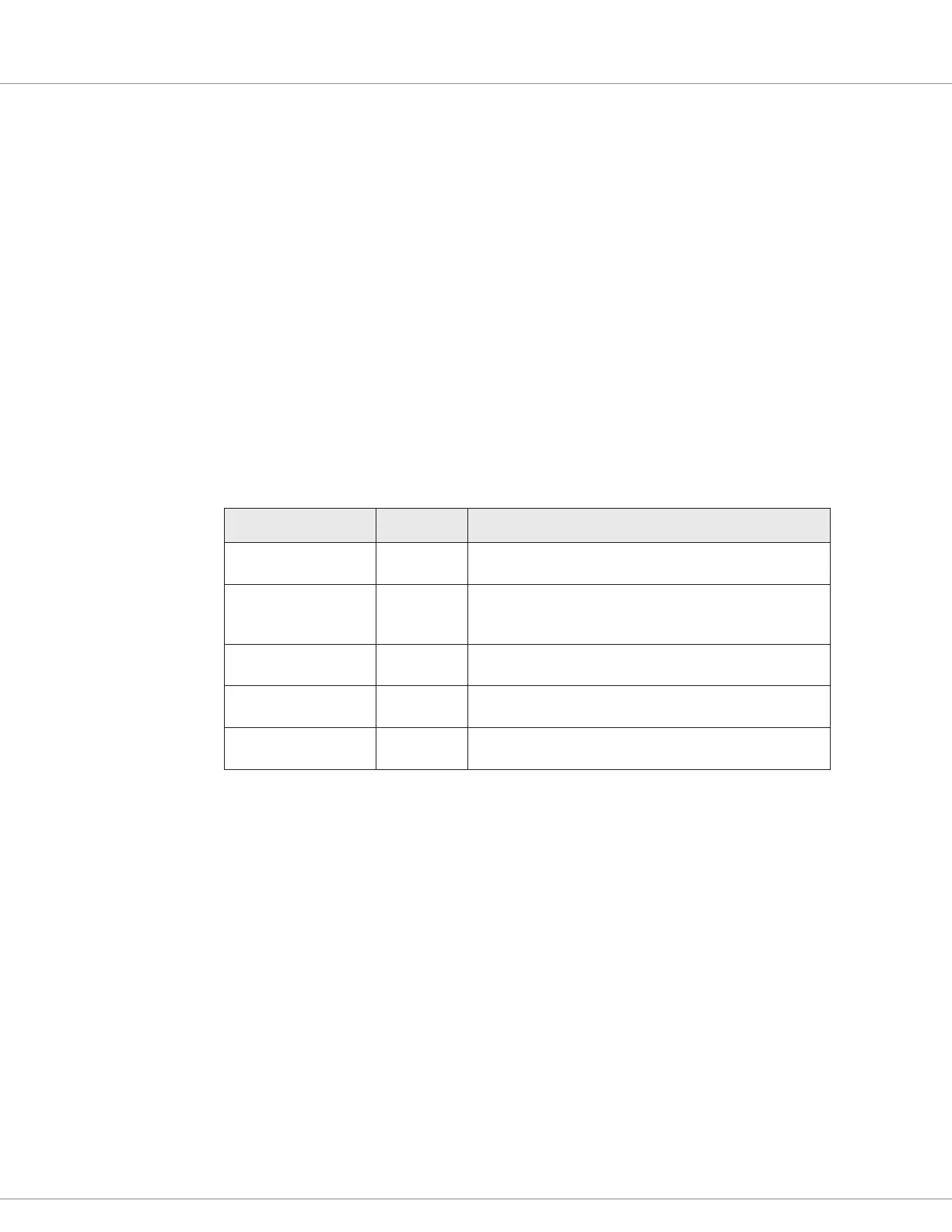

e following brake processing variables are accessible by VCL:

VCL Variable

CAN Object Index

Access Description

Pot2_Raw

0x3217 0x00

Read Only Voltage measurement at pin 17.

OS_Brake

0x3519 0x00

Read Only

Brake pot value after mapping, to be used in VCL when VCL

Brake Enable = On and Brake Type = 1–3.

Scale: 0 – 100%, 0 – 32767

VCL_Brake

0x3219 0x00

Read/Write VCL-accessible brake command.

Mapped_Brake

0x3212 0x00

Read Only Brake pot value after mapping.

Brake_Command

0x321A 0x00

Read Only Command resulting from brake processing.

Control Mode and Motor Control Processing

Figure 19 begins with the rottle_Command and Brake_Command inputs and routes the signals

according to the selected control mode. For the speed modes, a switch will zero the Throttle_

Command if the Brake_Command is any value but 0%. e signal chains are then directed to Speed

Mode Express, Speed Mode, or Torque Mode based on Control Mode Select. Note that in Torque

Mode there is no emergency reverse. (Note: emergency reverse is not applicable to the 1239E/1269E

controller’s on-road applications).

e control mode function uses algorithms to convert the incoming throttle and brake signals, the

motor rpm, and associated parameter settings into a Controller Torque Command.

Based upon the control mode selected, the desired Controller Torque Command is calculated, which

is passed to the Motor Control block (see Figure 18). e Motor Control block uses its mathematical

model of the specic motor & technology to generate the high eciency three-phase outputs that

drive the AC motor via the cables connected to the U, V, and W terminals. For AC Induction motors,

504 motor characterizations are available using the Motor Type parameter, or a motor can be user

characterized (Motor Type 0) following the procedures in Chapter 8A.

Quick Links:

Figure 18 p.112

Figure 19 p.114

Motor Type p.60

Automated Characterization

AC Induction motors p.93

Quick Links:

Brake Menu

Brake parameters p.51

Current Limits Menu

Brake Current Limit p.46

Brake Taper Speed p.44

Monitor Inputs

Brake Command p.77

Pot2_Raw p.77

Figure 18 p.112

Figure 19 p.114

Loading...

Loading...