2 — INSTALLATION AND WIRING

Curtis 1239E-1269E Manual, os 37.0 RevA – May 2021

Return to TOC

pg. 4

2 — INSTALLATION AND WIRING

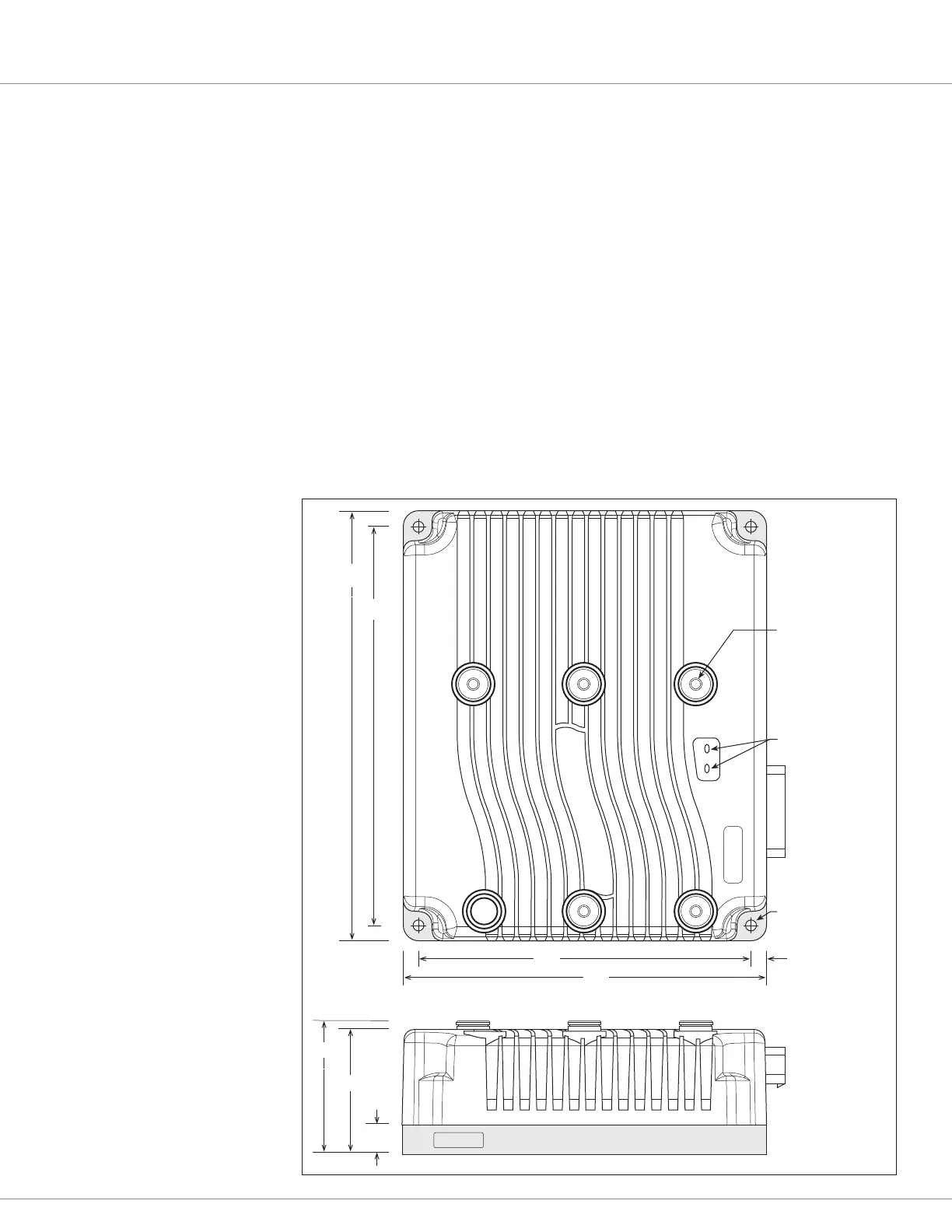

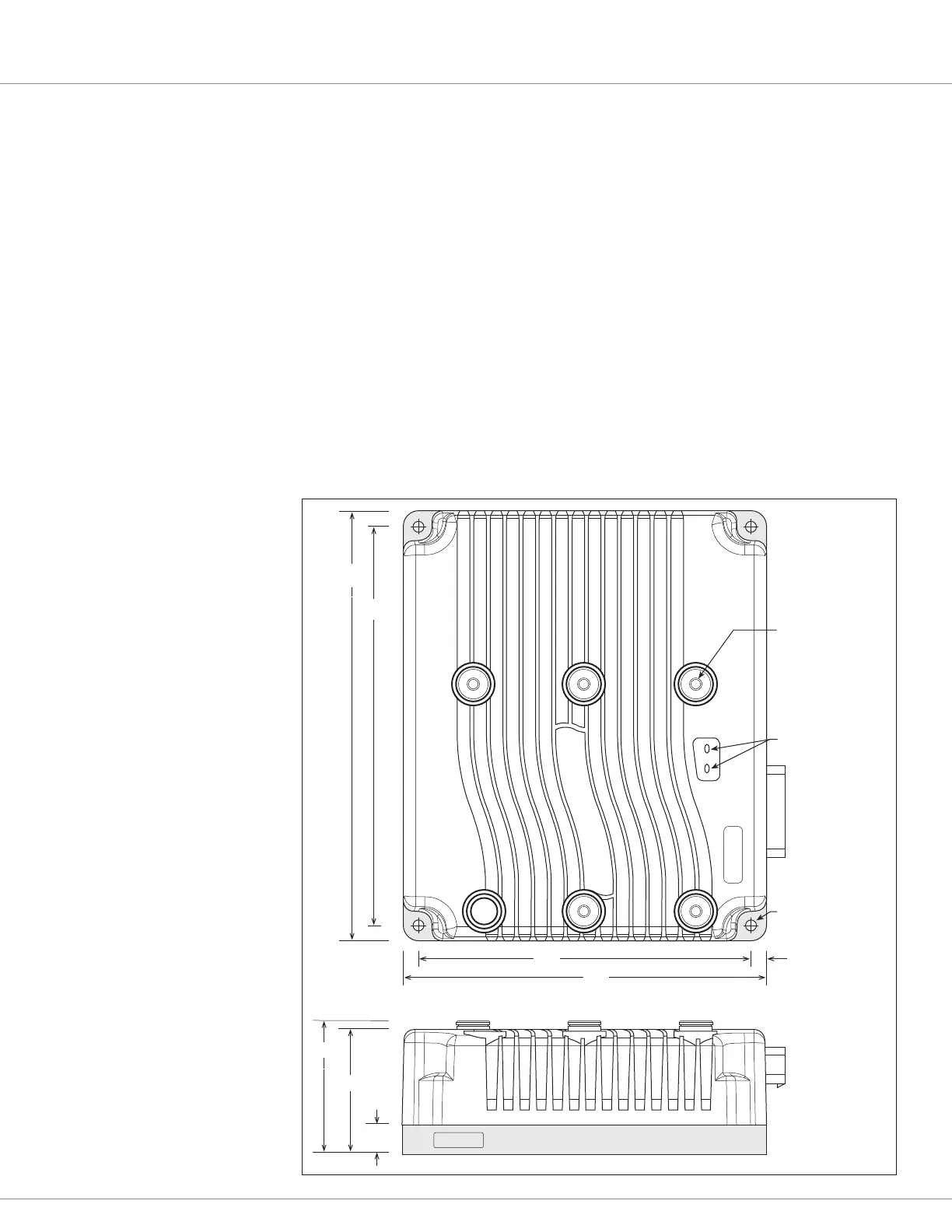

MOUNTING THE CONTROLLER

e outline and mounting hole dimensions for the 1239E controller are shown in Figure 3. Figure 4 is

the 1269E. When an Ampseal plug housing is mated with the 35-pin logic receptacle, these controllers

meet the IP65 requirements for environmental protection against dust and water. Nevertheless, in

order to prevent external corrosion and leakage paths from developing, the mounting location

should be carefully chosen to keep the controller as clean and dry as possible.

Mount the controller to a at surface devoid of protrusions, ridges, or a curvature that can cause damage

or distortion to its heatsink (the base plate). Secure the controller using four 6 mm (1/4") diameter bolts

evenly torqued to the vehicle’s mounting surface. ese controller’s heatsink (bottom surface) have a

typical roughness grade of N8 (ISO 1302), with a atness tolerance of < 5 mm (0.13 per 25 mm). A

thermal joint compound is recommended to improve heat conduction from the controller heatsink to

the vehicle’s mounting surface. Typically, when properly mounted to a larger metal surface, additional

heat-sinking or fan-cooling is not necessary to meet the application’s peak and continuous current ratings.

B

-

B

+

FUSE

U

V

W

M8 × 1.25,

5 plcs

19

80

85

212

232

10

Status LEDs

7 dia.,

4 plcs

255

275

Figure 3

Mounting dimensions in mm

for the Curtis 1239E motor

controller.

Loading...

Loading...