unit installation

IM 930-6 •EnnityVerticalWaterSourceHeatPumps 10 www.DaikinApplied.com

Piping

1. Allunitsshouldbeconnectedtosupplyandreturn

pipinginatwo-pipereversereturnconguration.A

reversereturnsystemisinherentlyself-balancing

andrequiresonlytrimbalancingwheremultiple

quantitiesofunitswithdifferentowandpressuredrop

characteristicsexistinthesameloop.Checkforproper

waterbalancebymeasuringdifferentialtemperature

readingacrossthewaterconnections.Forproper

waterow,thedifferentialtemperatureshouldbe12°F

to14°F(5°Cto8°C)forunitsincoolingmode.

Adirectreturnsystemmayalsowork,butproperwater

owbalancingismoredifculttoachieveandmaintain.

2. Thepipingcanbesteel,copperorPVC.

Note: If using PVC (schedule-40) construction grade

pipe or better, use the manufacturers recom-

mended high temperature adhesive. With PVC

piping the appropriate number of hanger brackets

must be used to help prevent sagging.

3. Supplyandreturnrunoutsusuallyjointheunitviashort

lengthsofhighpressureexiblehosewhicharesound

attenuatorsforbothunitoperatingnoiseandhydraulic

pumpingnoise.Oneendofthehoseshouldhave

aswivelttingtofacilitateremovalforservice.Hard

pipingalsocanbebroughtdirectlytotheunit.This

optionisnotrecommendedsincenovibrationornoise

attenuationcanbeaccomplished.Thehardpiping

musthaveunionstofacilitateunitremoval.SeeFigure

8,Figure9,andFigure10fortypicalpipingdetails.

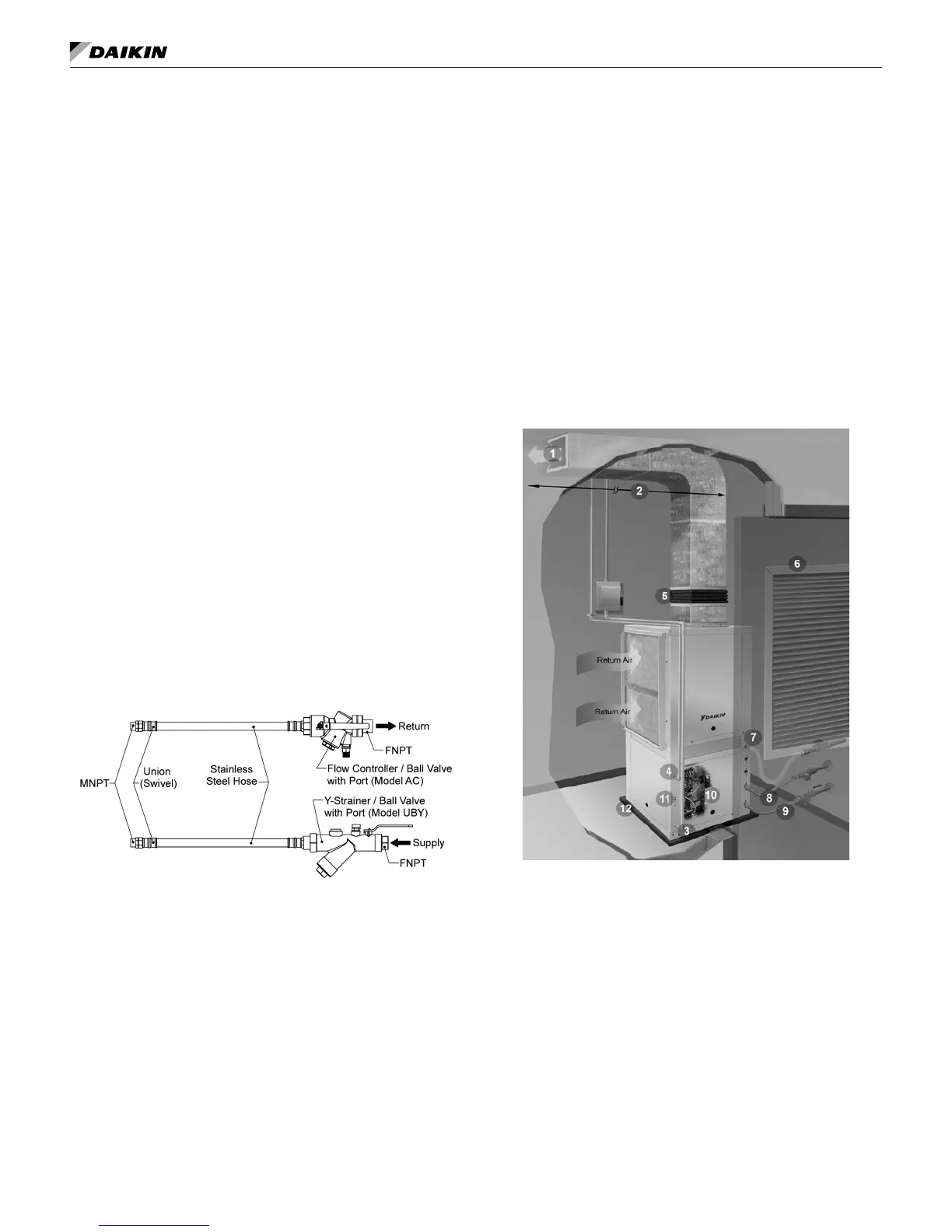

Figure 8: Typical Vertical Unit Piping

4. Someexiblehosethreadedttingsaresuppliedwith

sealantcompound.Ifnot,applyTeontapeforatightseal.

5. Supplyandreturnshutoffvalvesarerequiredat

eachunit.Thereturnvalveisusedforbalancingand

shouldhavea“memorystop”sothatitcanalways

beclosedoffbutcanonlybereopenedtotheproper

positionfortheowrequired.

6. Donotconnectanyunittothesupplyandreturnpiping

untilthewatersystemhasbeencleanedandushed

completely.Afterthecleaningandushinghastaken

place,theinitialconnectionshouldhaveallvalveswide

openinpreparationforwatersystemushing(see

"Cleaning&FlushingWaterSystem"onpage8).

7. Condensatepipingcanbesteel,copperorPVC.

Eachunitincludesacondensateconnection.

8. Unitsareinternallytrapped.

9. Donotlocateanypointinthedrainsystemabove

thedrainconnectionofanyunit.

10. Automaticowcontrolleddevicesmustnotbe

installedpriortosystemcleaningandushing.

11. Ahighpointofthepipingsystemmustbevented.

12. Checklocalcodefortheneedfordielectricttings.

Note: Do not over-torque ttings. The maximum torque

without damage to ttings is 30 foot pounds. If a

torque wrench is not available, use as a rule of

thumb, nger-tight plus one quarter turn.

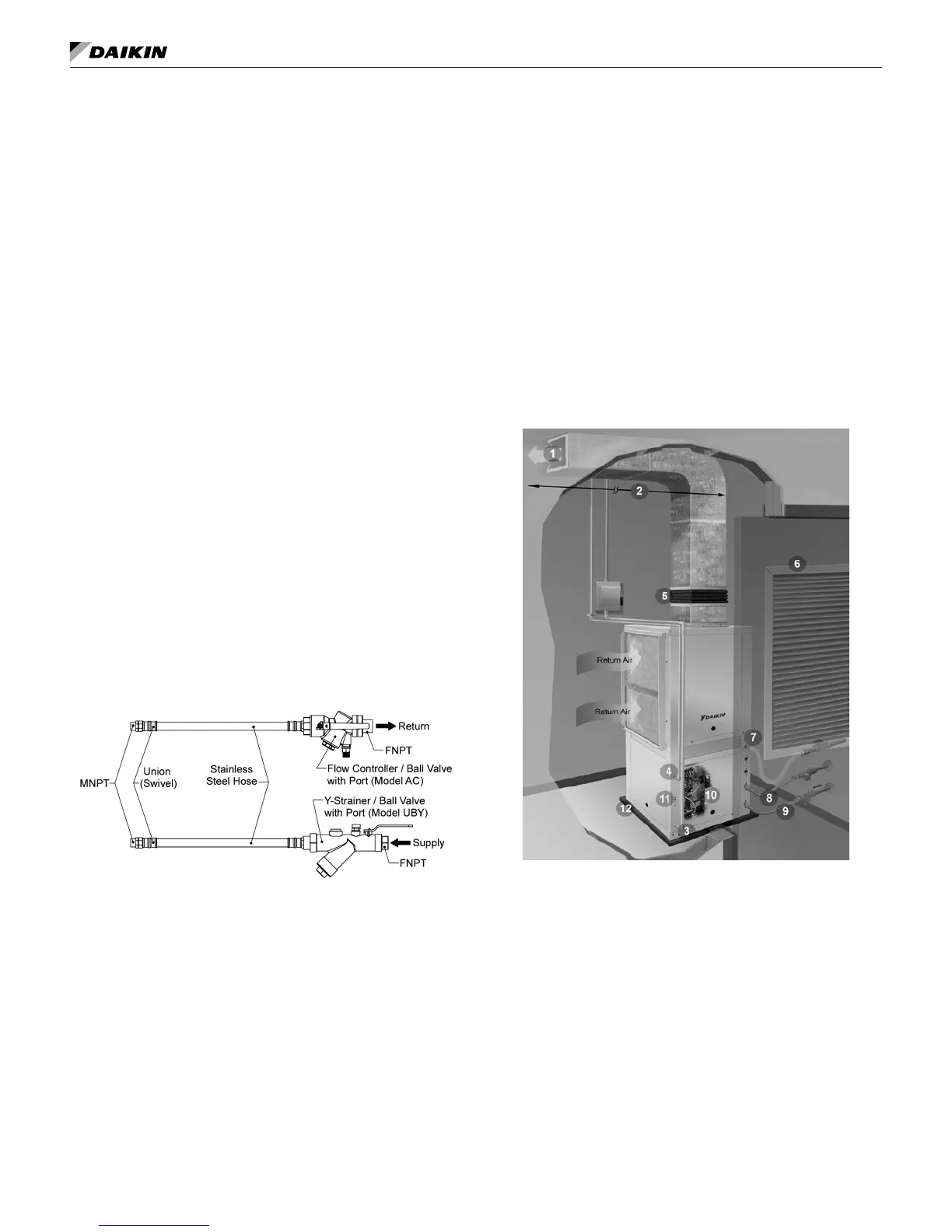

Figure 9: Typical Vertical Installation and Unit Piping

1 SupplyAirDucting

2 AcousticalThermalLining(10ft.)

3 LineVoltage-7/8"(22mm)Hole

4 LowVoltage-7/8"(22mm)Hole

5 FlexibleDuctCollar

6 LouveredDoorforReturnAir

7 CondensateDrainConnection

8 FlexibleReturnHosewithFlowController/BallValve(3/4"FPT)

9 FlexibleSupplyHosewithY-Strainer/BallValve(3/4"FPT)

10 AccessPaneltoController

11 LEDAnnunciatorStatusLights

12 VibrationIsolationPad

Loading...

Loading...