15 | Piping installation

Installer and user reference guide

85

SV1A25AJV1B+SV4~8A14AJV1B

VRV 5 safety valve unit

4P749917-1 – 2023.09

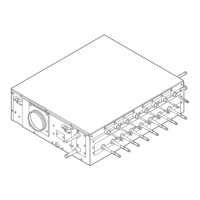

c

d

b

a

Ø

6.35

mm

Ø

9.5

mm

Ø

12.7

mm

Ø

15.9

mm

Ø

9.5

mm

a Liquid branch pipe

b Gas branch pipe

c Liquid header pipe

d Gas header pipe

3 Connect the branch pipes. The liquid and gas branch pipe diameters to be

used depend on the connected indoor unit capacity class. For information on

which branch pipes to connect, see "To set the DIP switches when joining

branch pipe ports"[497].

4 Install stopper pipes (accessory) for unused header pipes (when the SV unit is

not connected in refrigerant flow-through with another SV unit) and unused

branch pipes (when no indoor unit is connected to that branch pipe port).

15.3.2 To braze the pipe end

DANGER: RISK OF BURNING/SCALDING

NOTICE

Precautions when connecting field piping. Add brazing material as shown in the

figure.

▪ When brazing, blow through with nitrogen to prevent creation of large quantities

of oxidised film on the inside of the piping. This film adversely affects valves and

compressors in the refrigerating system and prevents proper operation.

▪ Set the nitrogen pressure to 20kPa (0.2bar) (just enough so it can be felt on the

skin) with a pressure-reducing valve.

a Refrigerant piping

b Part to be brazed

c Taping

d Manual valve

e Pressure-reducing valve

f Nitrogen

▪ Do NOT use anti-oxidants when brazing pipe joints. Residue can clog pipes and

break equipment.

Loading...

Loading...