15 | Piping installation

Installer and user reference guide

86

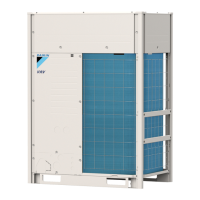

SV1A25AJV1B+SV4~8A14AJV1B

VRV 5 safety valve unit

4P749917-1 – 2023.09

▪ Do NOT use flux when brazing copper-to-copper refrigerant piping. Use phosphor

copper brazing filler alloy (BCuP), which does NOT require flux.

Flux has an extremely harmful influence on refrigerant piping systems. For

instance, if chlorine based flux is used, it will cause pipe corrosion or, in

particular, if the flux contains fluorine, it will deteriorate the refrigerant oil.

▪ ALWAYS protect the surrounding surfaces (e.g. insulation foam) from heat when

brazing.

15.3.3 Joining branch pipe ports

To make a connection with e.g. FXMA200A and FXMA250A, join branches with

joint kit EKBSJK. Only the following combinations are possible. E.g.: it is not possible

to join ports B and C.

Note: When using the joint kit, change the DIP switch settings. See "16.4To set the

DIP switches"[496].

Model Possible port combinations

SV4A A+B C+D

SV6A E+F

SV8A G+H

15.4 To insulate the refrigerant piping

After finishing the leak test and vacuum drying, the piping must be insulated. Take

into account the following points:

To insulate stopper pipes

In case of stopper pipes: install stopper pipe insulation tubes (accessory). Adding

additional insulation might be required depending on the ambient conditions.

Follow the rules for the total minimum insulation thickness.

1 Attach an insulation tube against the tube on the SV unit.

2 Apply a tape to close the seam so that air does not enter.

a Insulation tube (accessory)

b Cut surface (branch pipes only)

c Tape (field supply)

d Insulation tube (attached to the SV unit)

e SV unit

f Adherence surface

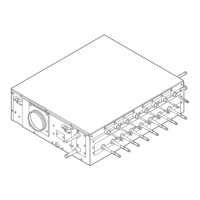

To insulate the header and branch pipes (standard insulation)

The header pipes and branch pipes MUST be insulated (field supply). Make sure

that the insulation is properly mounted over the header and branch pipes of the

unit as shown in the image below. Always use tape (field supply) to prevent air

gaps in the seam between the insulation tubes.

Loading...

Loading...