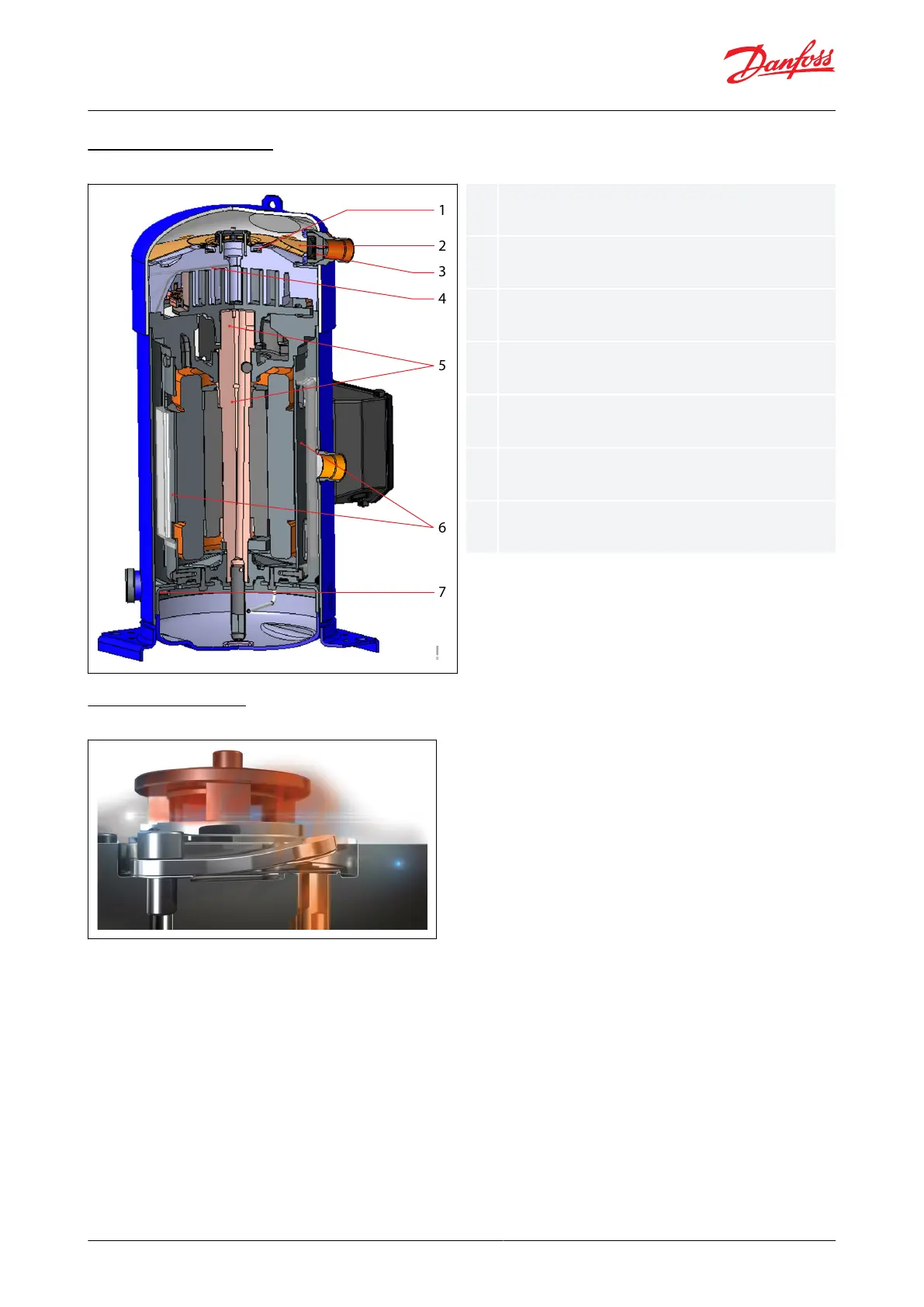

Intermediate discharge valves (IDVs) increase

seasonal eciency

Heat shield lowers the heat transfer between

discharge and suction gas and the sound level

Internal Non Return Valve (INRV) prevents

excessive leak rate from high pressure side

Integrated discharge gas temperature protection

(DGT)

Lead free polymer bearings improve behavior

under poor lubrication conditions

Patented gas path ow with gas intake design

induce higher resistance to liquid slugging

Organ pipe masters oil circulation in manifold

conguration

Cut Away DSH240-600

Figure 2: Cut Away DSH240-600

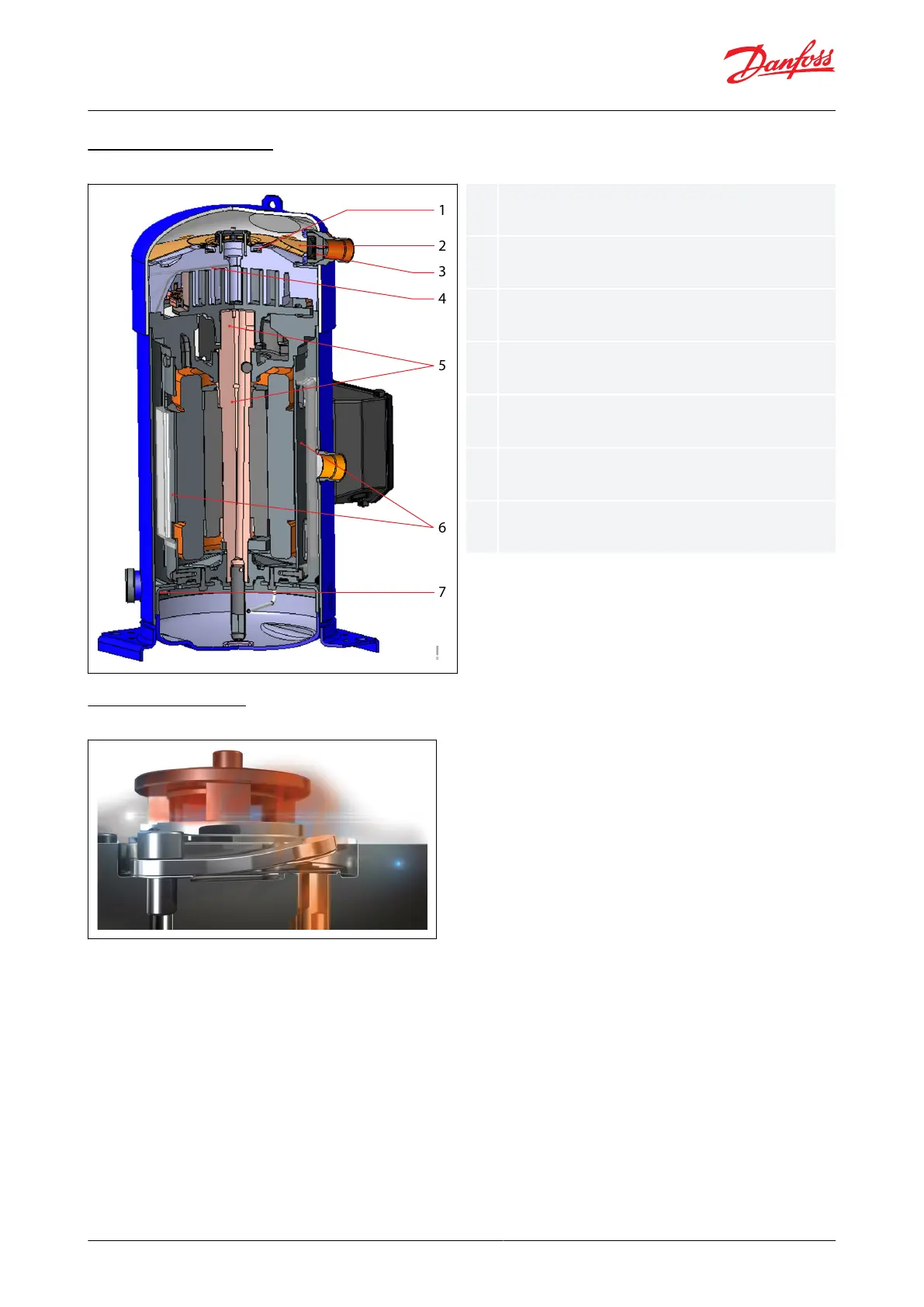

How do IDVs work?

Figure 3: Intermediate Discharge Valve (IDV)

Danfoss Intermediate Discharge Valves (IDVs) are located close to the discharge side of the compressor. They reduce

excessive compression of refrigerant under part-load conditions while maintaining the same cooling capacity. The

IDVs open when discharge pressure falls below the built-in optimization point. They adapt the eort of the motor to

the varying load and pressure conditions in the system, thus reducing the eort of the motor and its electrical

consumption and improving the system’s seasonal energy eciency.

© Danfoss | Climate Solutions | 2022.10 AB288965961751en-001402 | 7

Scroll compressors, DSH090 to DSH600 | Introduction

Loading...

Loading...