Table 35: Charge limits for Trio models

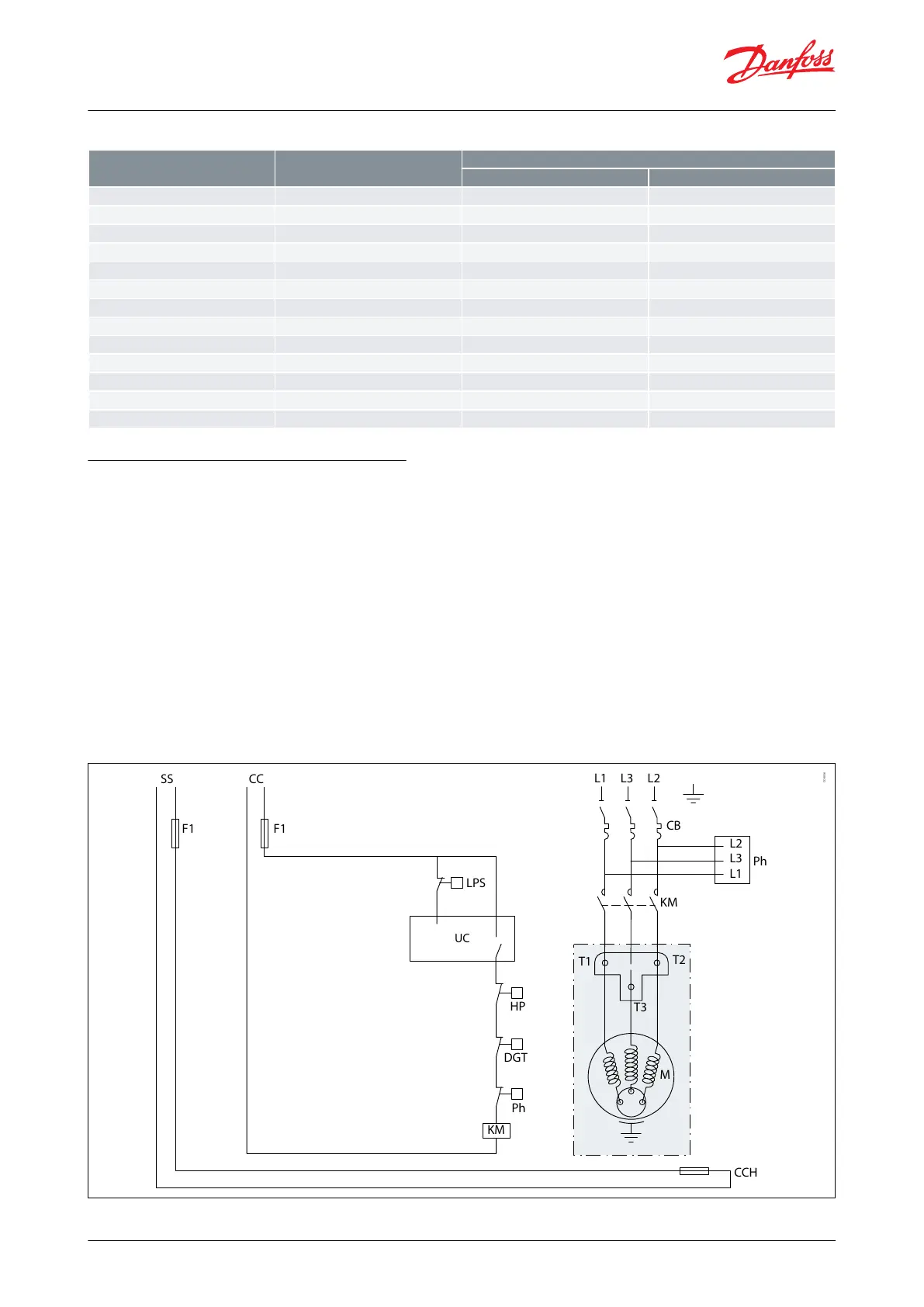

Power supply and electrical protection

Wiring information Requirements

•

Protect the compressor from short circuit and overcurrent by a thermal magnetic motor circuit breaker set to Max.

operating current or lower (see table in section Three phase electrical characteristics). For

DSH090-105-120-140-161-184, phase sequence protection is strongly recommended.

• Compressor models DSH240-295-381-485-600 are delivered with a pre-installed motor protection module inside

the terminal box that must be powered on.

• HP safety switch, DGT (only for DSH090 to DSH184) and electronic module relay output (M1-M2, only for DSH240

to DSH600) must be wired in the safety chain. Other safety devices such as LP can be either hardware or software

managed.

• Provide separate electrical supply for the heaters so that they remain energized even when the machine is out of

service (e.g. seasonal shutdown).

The wiring diagrams below are examples for a safe and reliable compressor wiring:

Figure 59: Compressor model DSH 090 - 105 - 120 - 140 - 161 - 184

CC-0036

M

DGT

HP

UC

SS CC

F1 F1

KM

CB

Ph

L1

L1

L3 L2

L3

L2

T1

T3

T2

KM

CCH

LPS

Ph

Scroll compressors, DSH090 to DSH600 | Application

© Danfoss | Climate Solutions | 2022.10 AB288965961751en-001402 | 54

Loading...

Loading...