FC 300 Profibus

How to Con figure the System

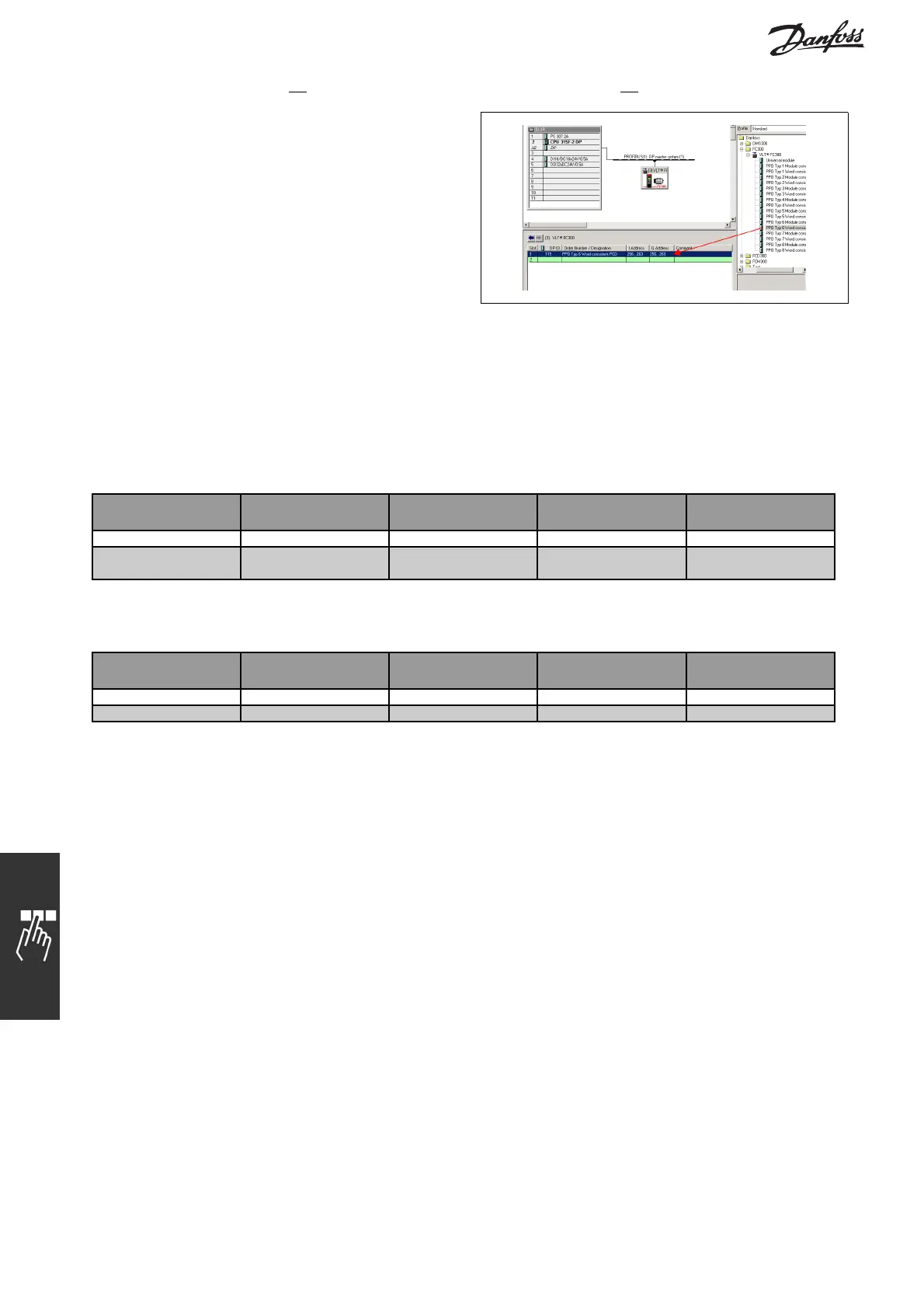

The next step is to set up the peripheral input and

output data. Data set up in the peripheral area is

transmitted cyclically via PPO types. In the example

below, a PPO type 6 Word consistent is dragged and

dropped to the first slot.

See the PPO types section in How to Control the FC

300 formoreinformation.

The configuration tool automatically assigns addresses in the peripheral address area. In this example the

input and output area have the following configuration:

PPO type 6:

PCD read (VLT to PLC)

PCD word

number

1 2 3 4

Input address 256-257 258-259 260-261 262-263

Set-up STW MAV Par. 9-16.2 Par. 9-16.3

PCD write (PLC to VLT)

PCD word

number

1 2 3 4

Output address 256-257 258-259 260-261 262-263

Set-up CTW MRV Par. 9-15.2 Par. 9-15.3

In PCDs 3 and 4 it is possible to assign Process signals. See an example of this in the Application Examples

chapter.

Download the configuration file to the PLC. The PROFIBUS system should be able to go online and it will start

to exchange data when the PLC is set to Run mode.

22

MG.33.C2.02 - VLT is a registered Danfoss trademark

Loading...

Loading...