4.2.5 IND

Some parameters in the frequency converter are array

parameters e.g. 3-10 Preset Reference. Since the Modbus

does not support arrays in the Holding registers, the

frequency converter has reserved the Holding register 9 as

pointer to the array. Before reading or writing an array

parameter, set the holding register 9. Setting holding

register to the value of 2, will cause all following read/

write to array parameters to be to the index 2.

4.2.6 Text Blocks

Parameters stored as text strings are accessed in the same

way as the other parameters. The maximum text block size

is 20 characters. If a read request for a parameter is for

more characters than the parameter stores, the response is

truncated. If the read request for a parameter is for fewer

characters than the parameter stores, the response is space

filled.

4.2.7

Conversion Factor

The different attributes for each parameter can be seen in

the section on factory settings. Since a parameter value

can only be transferred as a whole number, a conversion

factor must be used to transfer decimals.

4.2.8

Parameter Values

Standard data types

Standard data types are int16, int32, uint8, uint16 and

uint32. They are stored as 4x registers (40001–4FFFF). The

parameters are read using function 03HEX "Read Holding

Registers." Parameters are written using the function 6HEX

"Preset Single Register" for 1 register (16 bits), and the

function 10 HEX "Preset Multiple Registers" for 2 registers

(32 bits). Readable sizes range from 1 register (16 bits) up

to 10 registers (20 characters).

Non standard data types

Non standard data types are text strings and are stored as

4x registers (40001–4FFFF). The parameters are read using

function 03HEX "Read Holding Registers" and written using

function 10HEX "Preset Multiple Registers." Readable sizes

range from 1 register (2 characters) up to 10 registers (20

characters).

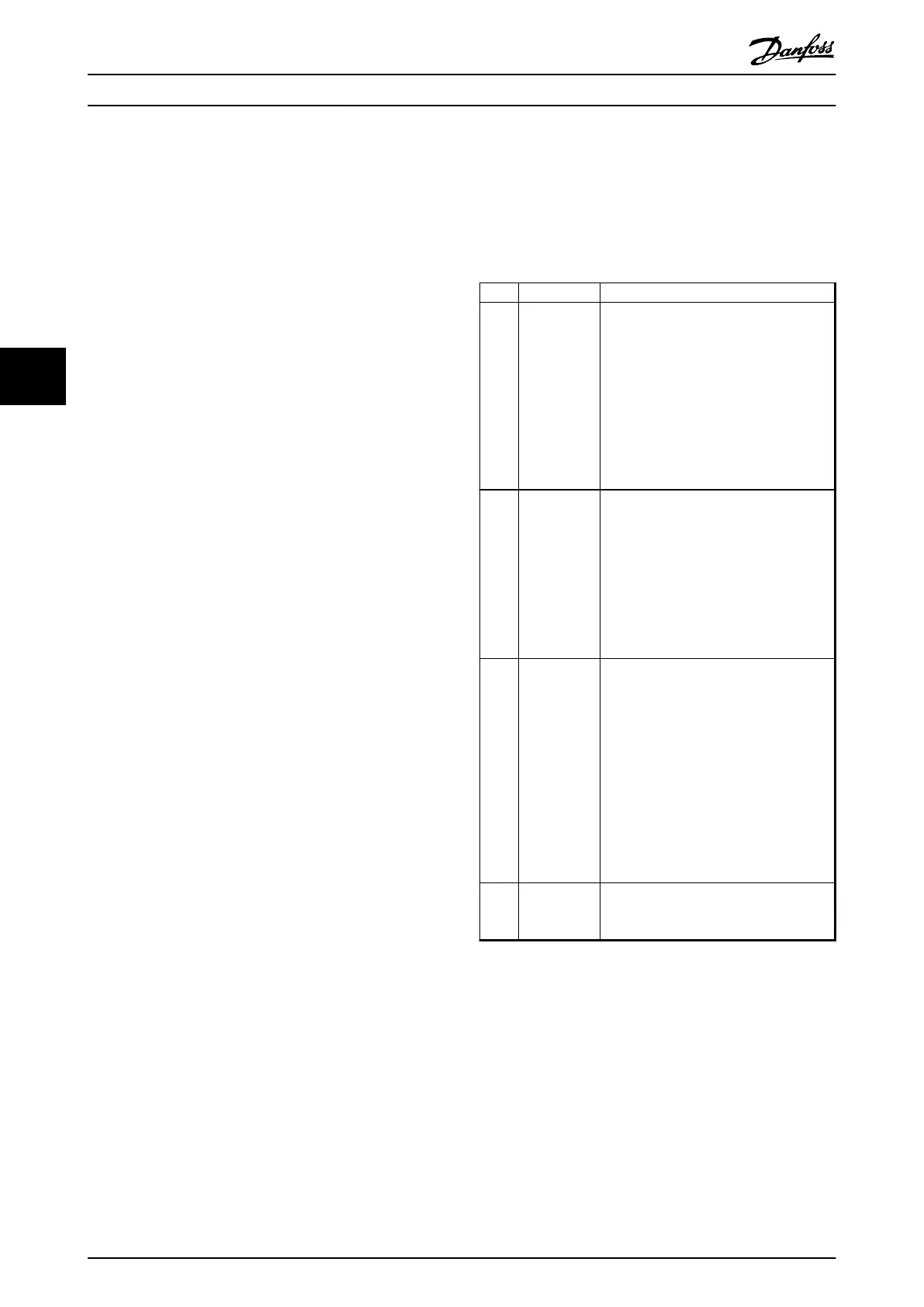

4.2.9

Modbus Exception Codes

For a full explanation of the structure of an exception code

response, refer to 4.2 Modbus TCP Message Framing

Structure.

Code Name Meaning

1 Illegal

function

The function code received in the query is

not an allowable action for the server (or

slave). This may be because the function

code is only applicable to newer devices,

and was not implemented in the unit

selected. It could also indicate that the

server (or slave) is in the wrong state to

process a request of this type, for

example because it is not configured and

is being asked to return register values.

2 Illegal data

address

The data address received in the query is

not an allowable address for the server

(or slave). More specifically, the

combination of reference number and

transfer length is invalid. For a controller

with 100 registers, a request with offset

96 and length 4 would succeed, a request

with offset 96 and length 5 generates

exception 02.

3 Illegal data

value

A value contained in the query data field

is not an allowable value for server (or

slave). This indicates a fault in the

structure of the remainder of a complex

request, such as that the implied length is

incorrect. It specifically does NOT mean

that a data item submitted for storage in

a register has a value outside the

expectation of the application program,

since the Modbus protocol is unaware of

the significance of any particular value of

any particular register.

4 Slave device

failure

An unrecoverable error occurred while the

server (or slave) was attempting to

perform the requested action.

Table 4.3 Modbus Exception Codes

How to Control MCA 122 Modbus TCP

18 MG90P202 - VLT

®

is a protected Danfoss trademark

44

Loading...

Loading...