Bit 09, Selection of ramp 1/2

Bit 09=‘0’ means that ramp 1 is active (3-40 Ramp 1 Type to

3-47 Ramp 1 S-ramp Ratio at Decel. Start). Bit 09=‘1’ means

that ramp 2 (3-50 Ramp 2 Type to 3-57 Ramp 2 S-ramp Ratio

at Decel. Start) is active.

Bit 10, Data not valid/Data valid

Is used to tell the frequency converter whether the control

word is to be used or ignored. Bit 10=“0” causes the

control word to be ignored, giving the opportunity to turn

off the control word when updating/reading parameters.

Bit 10=“1” causes the control word to be used. This

function is relevant, because the control word is always

contained in the telegram, regardless of which type of

telegram is used.

Bit 11, Relay 01

Bit 11=‘0’ Relay not activated. Bit 11 = ‘1’ Relay 01

activated, provided Control word bit 11 has been chosen in

5-40 Function Relay.

Bit 12, Relay 02

Bit 12=‘0’ Relay 02 has not been activated.

Bit 12=‘1’ Relay 02 has been activated, provided Control

word bit 12 has been chosen in 5-40 Function Relay.

Bit 13/14, Selection of set-up

Bits 13 and 14 are used to select one of 4 menu set-ups

according to Table 4.9:

Set-up

Bit 14 Bit 13

1 0 0

2 0 1

3 1 0

4 1 1

Table 4.9 Menu Set-ups

The function is only possible when Multi-Set-ups is selected

in 0-10 Active Set-up.

NOTICE

In 8-55 Set-up Select a selection is made to define how Bit

13/14 gates with the corresponding function on the digital

inputs.

Bit 15 Reverse

Bit 15=‘0’ causes no reversing.

Bit 15=‘1’ causes reversing.

NOTICE

In the factory setting reversing is set to digital in

8-54 Reversing Select. Bit 15 causes reversing only when Ser.

communication, Logic AND or Logic OR is selected.

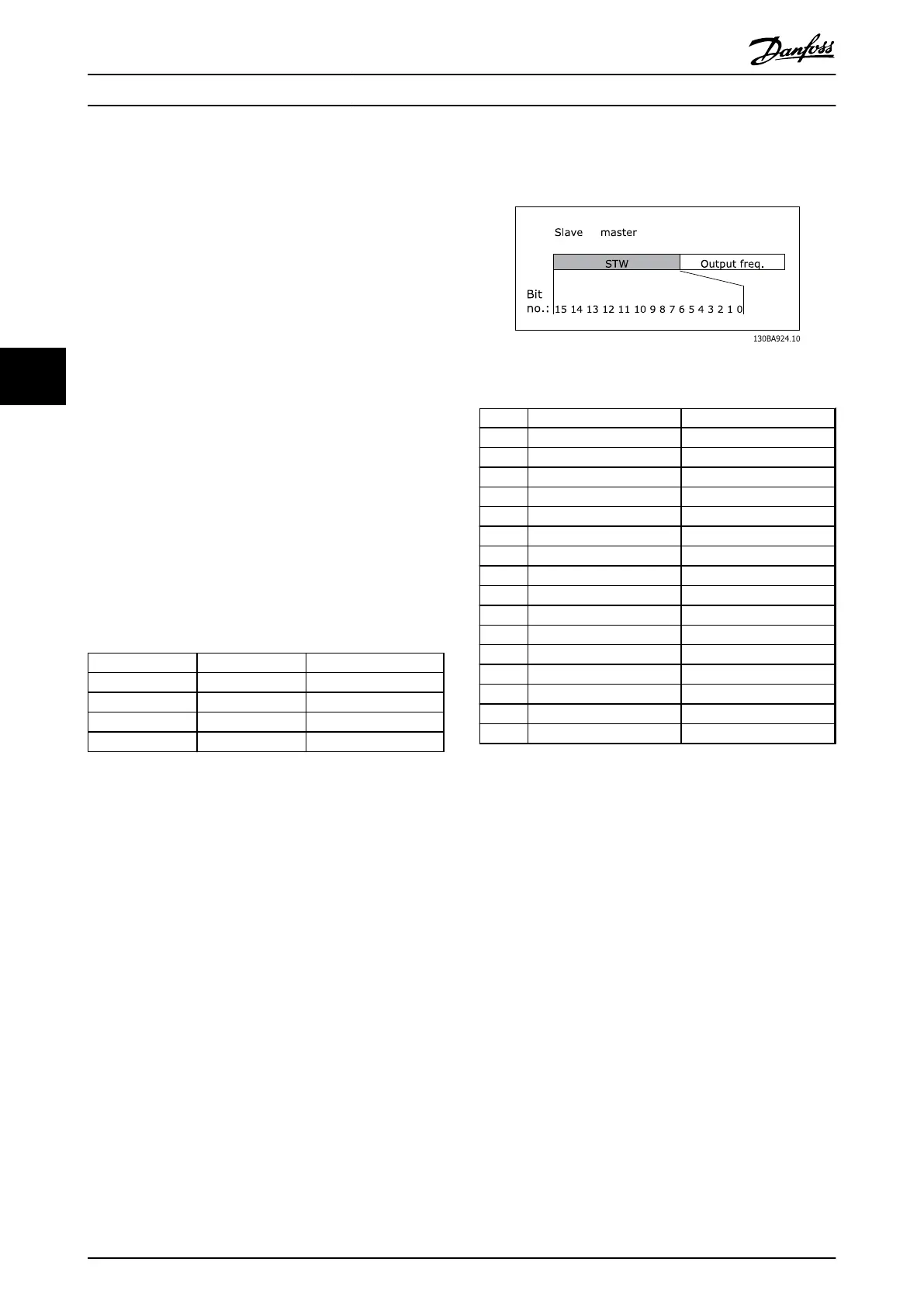

4.4.1 Status Word according to Frequency

Converter Profile (STW)

Illustration 4.3 8-10 Control Word Profile

Bit Bit value=0 Bit value=1

00 Control not ready Control ready

01 Drive not ready Drive ready

02 Coasting Enable

03 No error Trip

04 No error Error (no trip)

05 Reserved -

06 No error Trip lock

07 No warning Warning

08 Speed ≠ reference Speed = reference

09 Local operation Bus control

10 Out of frequency limit Frequency limit ok

11 No operation In operation

12 Drive ok Stopped, auto start

13 Voltage ok Voltage exceeded

14 Torque ok Torque exceeded

15 Thermal ok Thermal exceeded

Table 4.10 Staus Word Bits

Explanation of the status bits

Bit 00, Control ready

Bit 00=‘0’ means that the frequency converter has tripped.

Bit 00=‘1’ means that the frequency converter controls are

ready, but that the power component is not necessarily

receiving any power supply (in the event of external 24 V

supply to controls).

Bit 01, Drive ready

Bit 01=‘1’. The frequency converter is ready for operation.

Bit 02, Coasting stop

Bit 02=‘0’. The frequency converter has released the motor.

Bit 02=‘1’. The frequency converter can start the motor

when a start command is given.

Bit 03, No error/Trip

Bit 03=‘0’ means that the frequency converter is not in

fault mode.

Bit 03=‘1’ means that the frequency converter is tripped,

and that a reset signal is required to re-establish operation.

Bit 04, No error/Error (no trip)

Bit 04=‘0’ means that the frequency converter is not in

fault mode.

How to Control MCA 122 Modbus TCP

24 MG90P202 - VLT

®

is a protected Danfoss trademark

44

Loading...

Loading...