5.3.4

VLT

®

HVAC Solutions

5.3.4.1 Variable Air Volume

Variable air volume systems (VAV) are used to control both the ventilation and temperature to fulll the requirements of a

building. Central VAV systems are considered to be the most energy-ecient method to air condition buildings. Central

systems are more ecient than distributed systems.

The eciency comes from using larger fans and chillers, which have higher eciencies than small motors and distributed

air-cooled chillers. Savings are also realized from the decreased maintenance requirements.

VLT

®

solution

While dampers and IGVs work to maintain a constant pressure in the ductwork, a drive solution saves more energy and

reduces the complexity of the installation. Instead of creating an articial pressure drop or a decrease in fan eciency, the

drive decreases the speed of the fan to provide the ow and pressure required by the system.

Centrifugal devices, such as fans, decrease the pressure and ow they produce as their speed is reduced. Their power

consumption is reduced.

The return fan is frequently controlled to maintain a xed dierence in airow between the supply and return. The

advanced PID controller of the HVAC drive can be used to eliminate the need for more controllers.

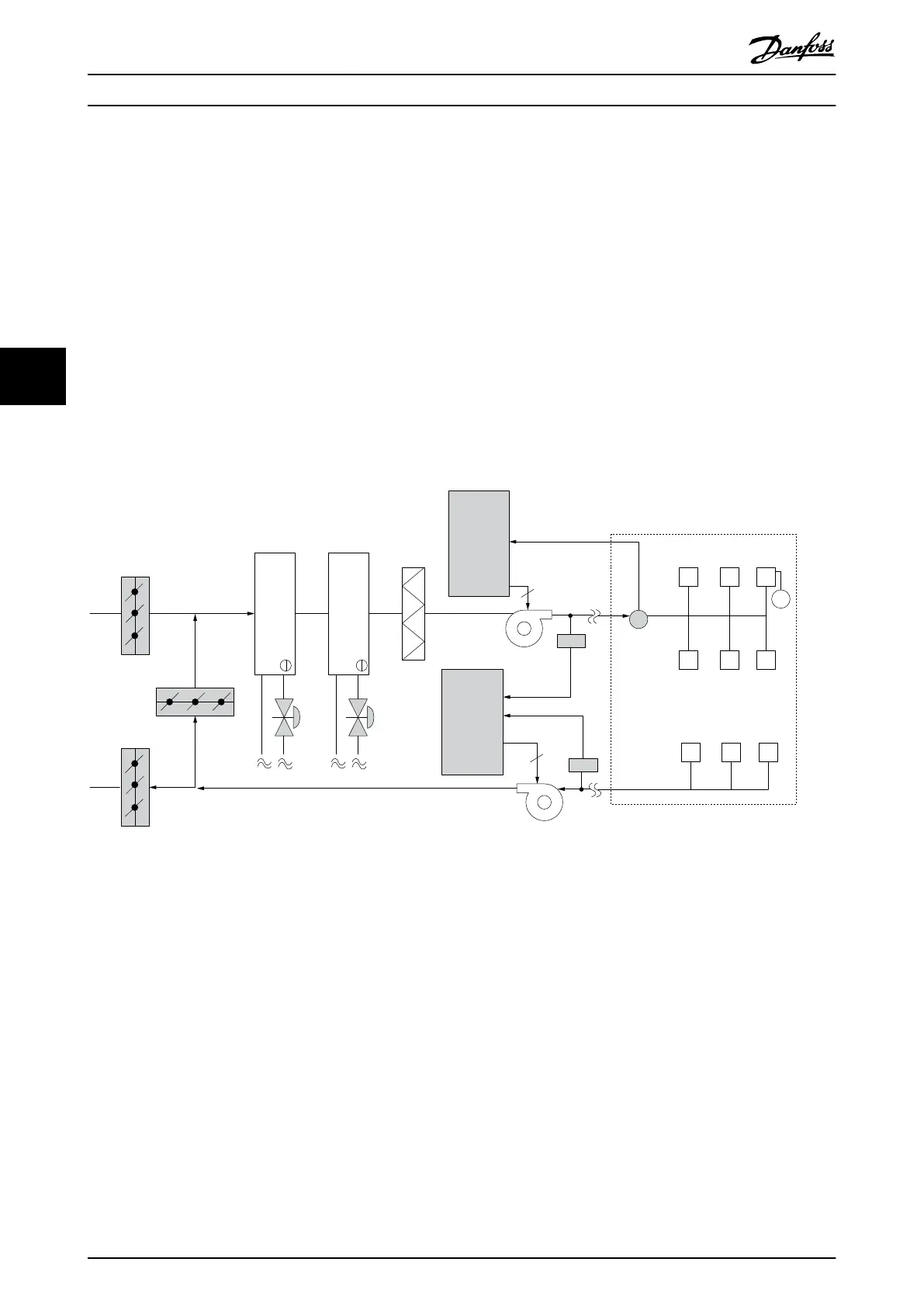

Frequency

converter

Frequency

converter

D1

D2

D3

Cooling coil

Heating coil

Filter

Pressure

signal

Supply fan

VAV boxes

Flow

Flow

Pressure

transmitter

Return fan

3

3

T

130BB455.10

Illustration 5.16 Drives Used in a Variable Air Volume System

For more information, consult the Danfoss supplier for the Variable Air Volume: Improving VAV Ventilation Systems application

note.

5.3.4.2 Constant Air Volume

Constant air volume (CAV) systems are central ventilation systems used to supply large common zones with the minimum

amounts of fresh tempered air. They preceded VAV systems and are found in older multi-zoned commercial buildings as

well. These systems preheat fresh air with air handling units (AHUs) that have heating coils. Many are also used for air

conditioning buildings and have a cooling coil. Fan coil units are often used to help with the heating and cooling

requirements in the individual zones.

VLT

®

solution

With a drive, signicant energy savings can be obtained while maintaining decent control of the building. Temperature

sensors or CO

2

sensors can be used as feedback signals to drives. Whether controlling temperature, air quality, or both, a

CAV system can be controlled to operate based on actual building conditions. As the number of people in the controlled

area decreases, the need for fresh air decreases. The CO

2

sensor detects lower levels and decreases the supply fan speed.

The return fan modulates to maintain a static pressure setpoint or xed dierence between the supply and return airows.

Product Features

VLT

®

HVAC Drive FC 102

32 Danfoss A/S © 11/2017 All rights reserved. MG16C302

55

Loading...

Loading...