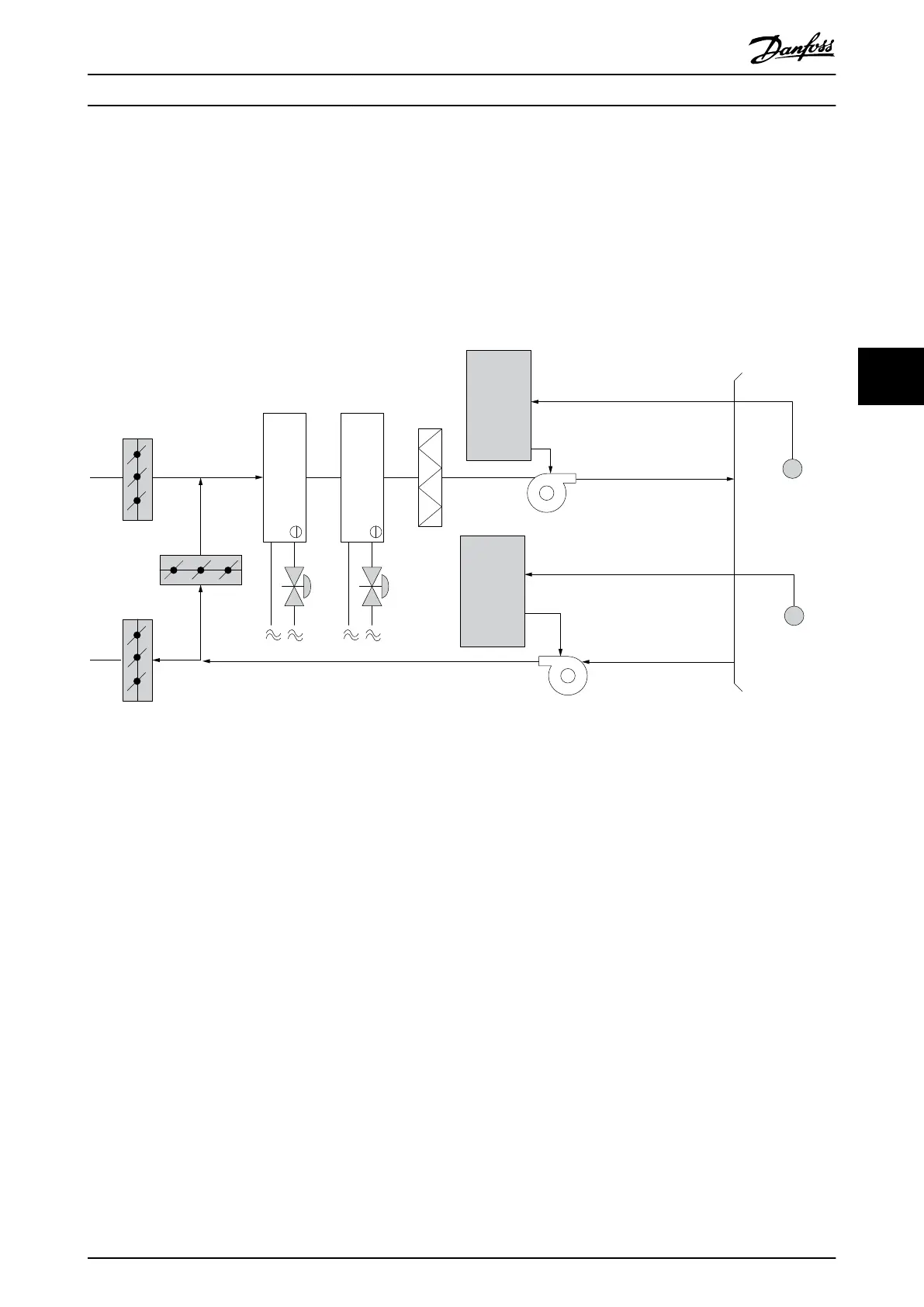

Temperature control needs vary based on outside temperature and number of people in the controlled zone. As the

temperature decreases below the setpoint, the supply fan can decrease its speed. The return fan modulates to maintain a

static pressure setpoint. Decreasing the airow, reduces the energy used to heat or cool the fresh air, resulting in further

savings.

Several features of the Danfoss HVAC dedicated drive can be used to improve the performance of a CAV system. One

concern of controlling a ventilation system is poor air quality. The programmable minimum frequency can be set to

maintain a minimum amount of supply air regardless of the feedback or reference signal. The drive also includes a 3-zone, 3

setpoint PID controller which allows monitoring both temperature and air quality. Even if the temperature requirement is

satised, the drive maintains enough supply air to satisfy the air quality sensor. The controller can monitor and compare 2

feedback signals to control the return fan by maintaining a xed dierential airow between the supply and return ducts.

Frequency

converter

Frequency

converter

Pressure

signal

Cooling coil

Heating coil

D1

D2

D3

Filter

Pressure

transmitter

Supply fan

Return fan

Temperature

signal

Temperature

transmitter

130BB451.10

Illustration 5.17 Drive Used in a Constant Air Volume System

For more information, consult the Danfoss supplier for the Constant Air Volume: Improving CAV Ventilation Systems application

note.

5.3.4.3 Cooling Tower Fan

Cooling tower fans are used to cool condenser water in water-cooled chiller systems. Water-cooled chillers provide the most

ecient means of creating chilled water. They are as much as 20% more ecient than air cooled chillers. Depending on

climate, cooling towers are often the most energy-ecient method of cooling the condenser water from chillers.

Cooling towers cool the condenser water by evaporation. The condenser water is sprayed into the cooling tower onto the

ll to increase its surface area. The tower fan blows air through the ll and sprayed water to aid in the evaporation.

Evaporation removes energy from the water, dropping its temperature. The cooled water collects in the basin of the cooling

tower where it is pumped back into the chiller condenser and the cycle is repeated.

VLT

®

solution

With a drive, the cooling tower fans can be controlled to the required speed to maintain the condenser water temperature.

The drives can also be used to turn the fan on and

o as needed. With the Danfoss VLT

®

HVAC Drive, as the cooling tower

fans drop below a certain speed, the cooling eect decreases. When using a gearbox to drive the tower fan, a minimum

speed of 40–50% could be required. The customer programmable minimum frequency setting is available to maintain this

minimum frequency even as the feedback or speed reference calls for lower speeds.

The drive can be programmed to enter a sleep mode and stop the fan until a higher speed is required. Additionally, some

cooling tower fans have undesirable frequencies that can cause vibrations. These frequencies can easily be avoided by

programming the bypass frequency ranges in the drive.

Product Features Design Guide

MG16C302 Danfoss A/S © 11/2017 All rights reserved. 33

5 5

Loading...

Loading...