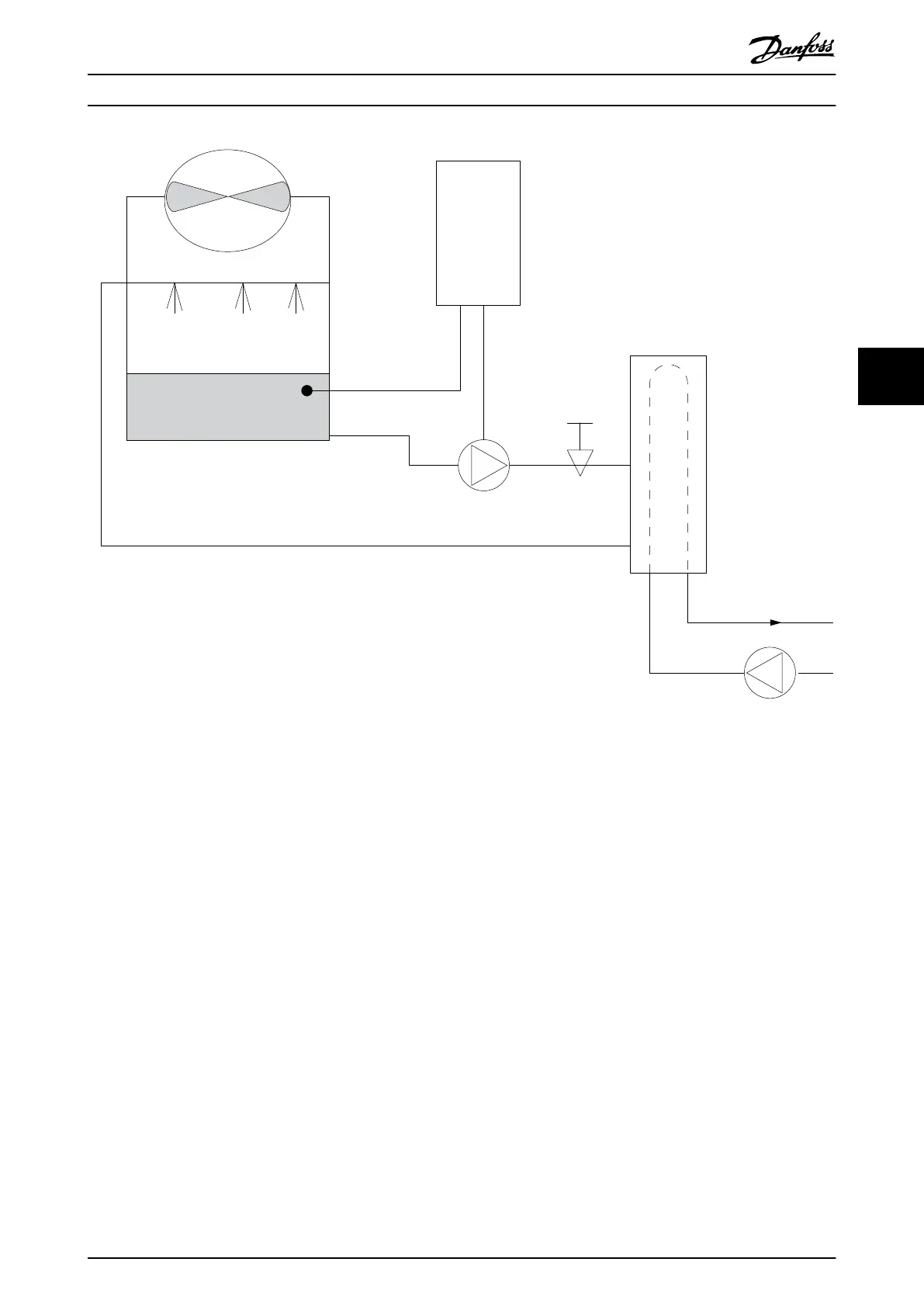

Frequency

converter

Water

Inlet

Water

Outlet

BASIN

Flow or pressure sensor

Condenser

Water pump

Throttling

valve

Supply

CHILLER

130BB452.10

Illustration 5.19 Drive Used with a Condenser Pump

For more information, consult the Danfoss supplier for the Condenser Pumps: Improving Condenser Water Pumping Systems

application note.

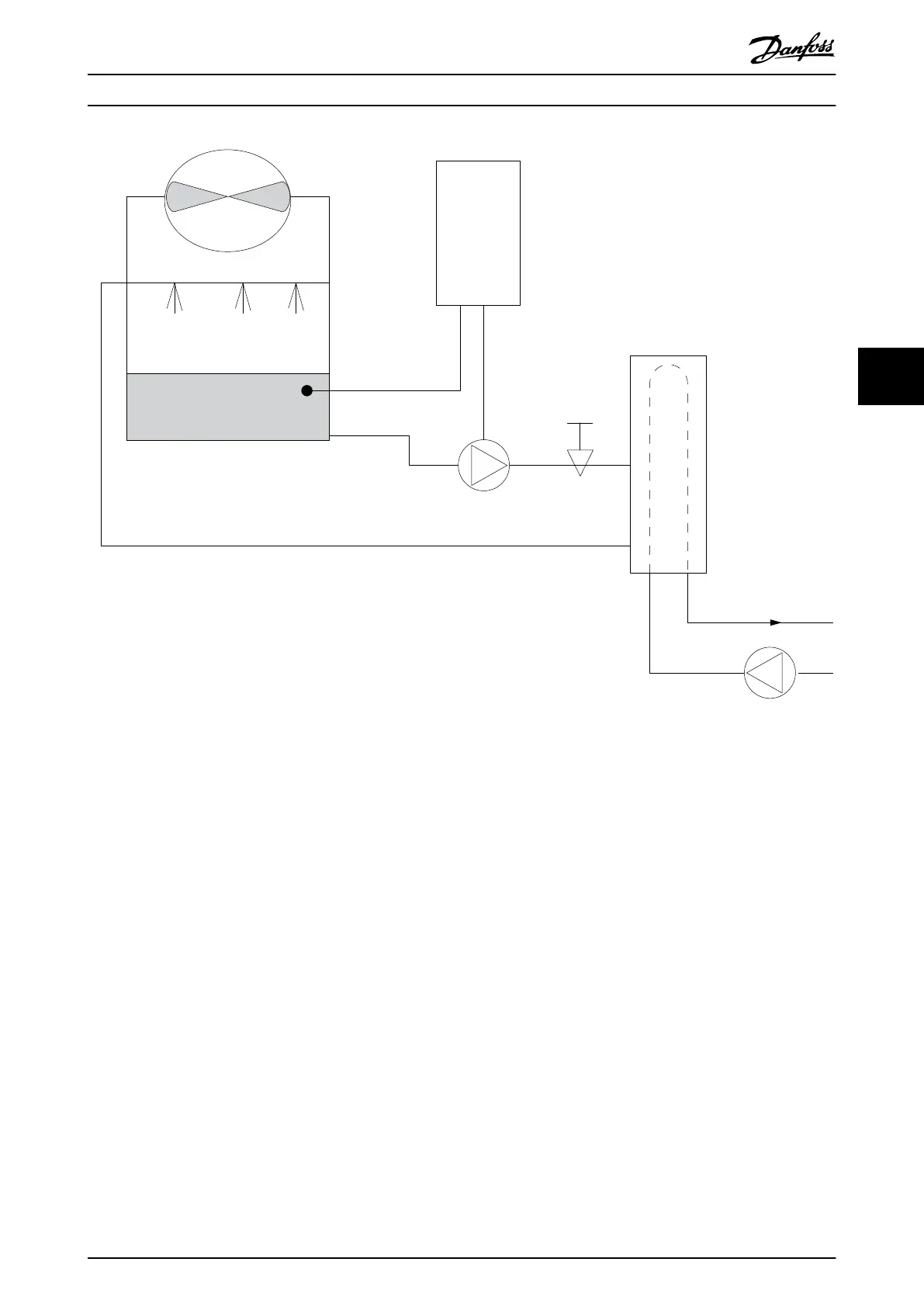

5.3.4.5 Primary Pumps

Primary pumps in a primary/secondary pumping system can maintain a constant ow through devices that encounter

operation or control diculties when exposed to variable ow. The primary/secondary pumping technique decouples the

primary production loop from the secondary distribution loop. Decoupling allows devices such as chillers to obtain constant

design ow and operate properly while allowing the rest of the system to vary in ow. As the evaporator ow rate

decreases in a chiller, the water begins to become overchilled. As the water becomes overchilled, the chiller attempts to

decrease its cooling capacity. If the ow rate drops far enough, or too quickly, the chiller cannot shed its load suciently

and the low evaporator temperature safety trips the chiller, requiring a manual reset. This situation is common in large

installations, especially when 2 or more chillers in parallel are installed if primary/secondary pumping is not used.

VLT

®

solution

A drive can be added to the primary system, to replace the throttling valve and/or trimming of the impellers, leading to

reduced operating expenses. Two control methods are common:

•

A ow meter installed at the discharge of each chiller can control the pump directly because the desired ow rate

is known and constant. Using the PID controller, the drive always maintains the appropriate ow rate, even

Product Features Design Guide

MG16C302 Danfoss A/S © 11/2017 All rights reserved. 35

5 5

Loading...

Loading...