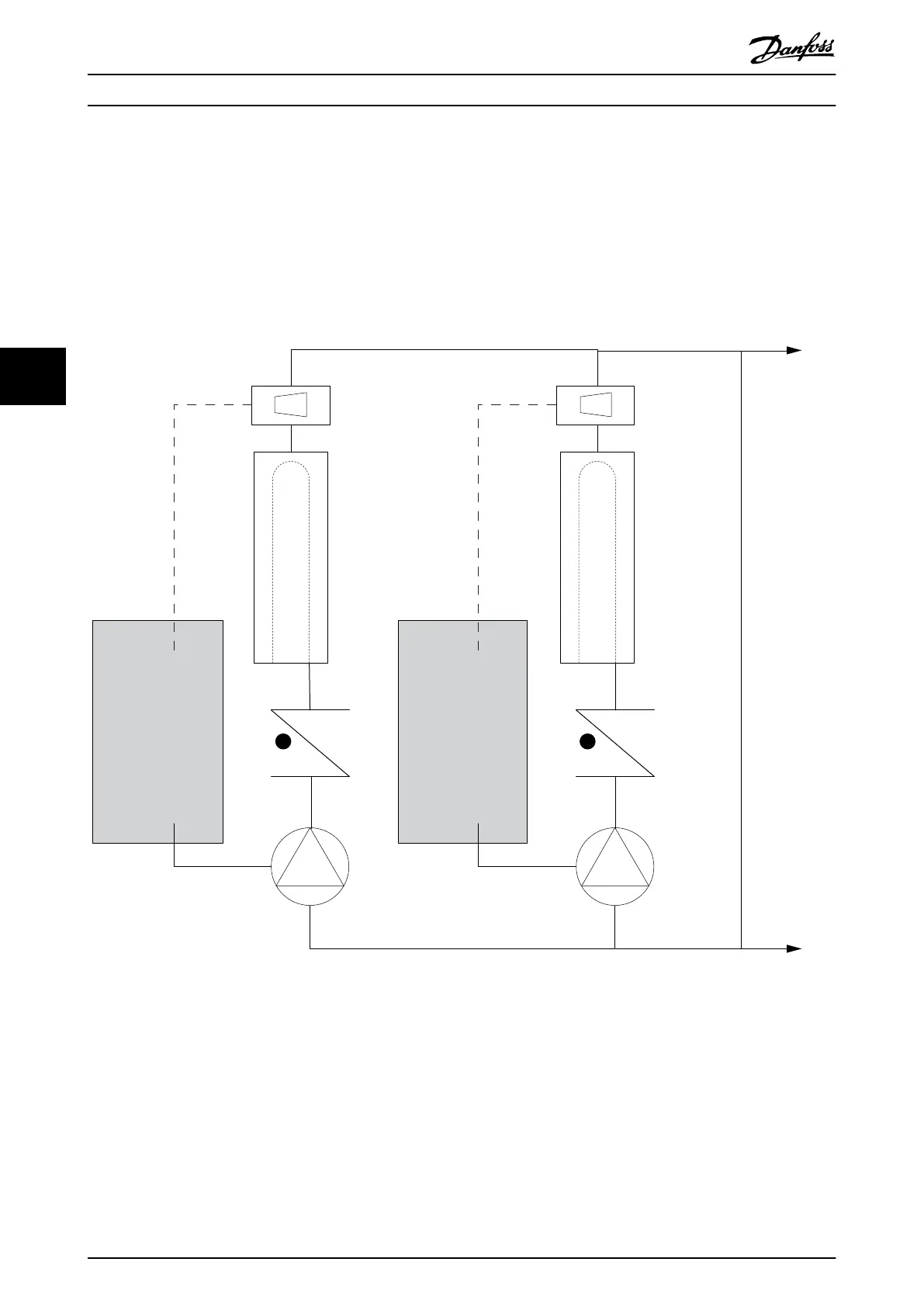

compensating for the changing resistance in the primary piping loop as chillers and their pumps are staged on

and o.

•

The operator can use local speed determination by decreasing the output frequency until the design ow rate is

achieved. Using a drive to decrease the pump speed is similar to trimming the pump impeller, but more ecient.

The balancing contractor simply decreases the speed of the pump until the proper ow rate is achieved and leaves

the speed xed. The pump operates at this speed any time the chiller is staged on. Because the primary loop lacks

control valves or other devices that can change the system curve, and the variance due to staging pumps and

chillers on and o is small, this xed speed remains appropriate. If the ow rate must be increased later in the life

of the system, the drive can simply increase the pump speed instead of requiring a new pump impeller.

Frequency

converter

Frequency

converter

CHILLER

CHILLER

Flowmeter

Flowmeter

F F

130BB456.10

Illustration 5.20 Drives Used with Primary Pumps in a Primary/Secondary Pump System

For more information, consult the Danfoss supplier for the Primary Pumps: Improving Primary Pumping in Pri/Sec System

application note.

Product Features

VLT

®

HVAC Drive FC 102

36 Danfoss A/S © 11/2017 All rights reserved. MG16C302

55

Loading...

Loading...