Shielding of cables

NOTICE

The motor cable must be shielded. If an unshielded cable

is used, some EMC requirements are not complied with.

Use a shielded motor cable to comply with EMC emission

specications. For more information, see

chapter 10.16 EMC-compliant Installation.

Avoid installation with twisted shield ends (pigtails). They

spoil the shielding eect at higher frequencies. If it is

necessary to break the shield, continue the shield at the

lowest possible HF impedance.

Connect the motor cable shield to both the decoupling

plate of the drive and the metal housing of the motor.

Make the shield connections with the largest possible

surface area (cable clamp) by using the installation devices

within the drive.

Cable length and cross-section

The drive has been EMC tested with a given length of

cable. Keep the motor cable as short as possible to reduce

the noise level and leakage currents.

Switching frequency

When drives are used together with sine-wave

lters to

reduce the acoustic noise from a motor, the switching

frequency must be set according to the instructions in

parameter 14-01 Switching Frequency.

Terminals Connection type

96 97 98 99

U V W

PE

1)

Motor voltage 0–100% of

mains voltage. 3 wires out of

motor.

U1 V1 W1

PE

1)

Delta-connected.

W2 U2 V2 6 wires out of motor.

U1 V1 W1

PE

1)

Star-connected U2, V2, W2.

U2, V2, and W2 to be intercon-

nected separately.

Table 10.1 Motor Cable Connections, Enclosures E1–E2 and

F1–F4

1) Protected ground connection

Terminals Connection type

96 97 98 99

U V W

PE

1)

Motor voltage 0–100% of

mains voltage.

3 wires out of motor.

U1 V1 W1

PE

1)

Delta-connected.

W2 U2 V2 6 wires out of motor.

U1 V1 W1

PE

1)

Star-connected U2, V2, W2.

U2, V2, and W2 to be intercon-

nected separately.

Table 10.2 Motor Cable Connections, Enclosures F8–F13

1) Protective ground connection

NOTICE

In motors without phase insulation, paper, or other

insulation reinforcement suitable for operation with

voltage supply, use a sine-wave lter on the output of

the drive.

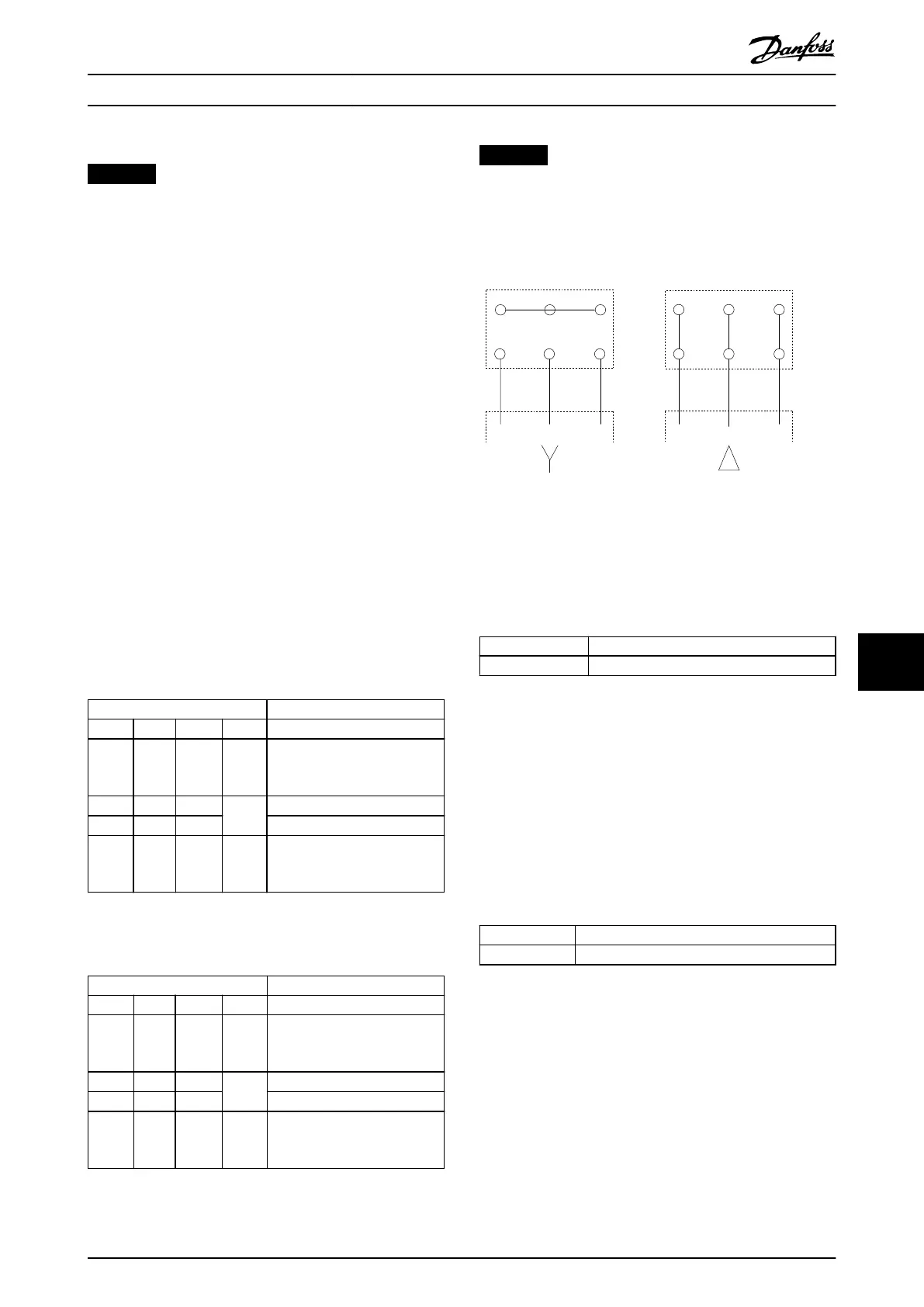

U

1

V

1

W

1

175ZA114.11

96 97 98

96 97 98

FC

FC

Motor

Motor

U

2

V

2

W

2

U

1

V

1

W

1

U

2

V

2

W

2

Illustration 10.5 Motor Cable Connection

10.3.2 DC Bus Connection

The DC bus terminal is used for DC back-up, with the DC

link being supplied from an external source.

Terminal Function

88, 89 DC Bus

Table 10.3 DC Bus Terminals

10.3.3 Load Sharing Connection

Load sharing links together the DC intermediate circuits of

several drives. For an overview, see chapter 5.6 Load Share

Overview.

The load sharing feature requires extra equipment and

safety considerations. Consult Danfoss for ordering and

installation recommendations.

Terminal Function

88, 89 Load sharing

Table 10.4 Load Sharing Terminals

The connection cable must be shielded and the maximum

length from the drive to the DC bar is limited to 25 m

(82 ft).

Electrical Installation Con... Design Guide

MG16C302 Danfoss A/S © 11/2017 All rights reserved. 169

10 10

Loading...

Loading...