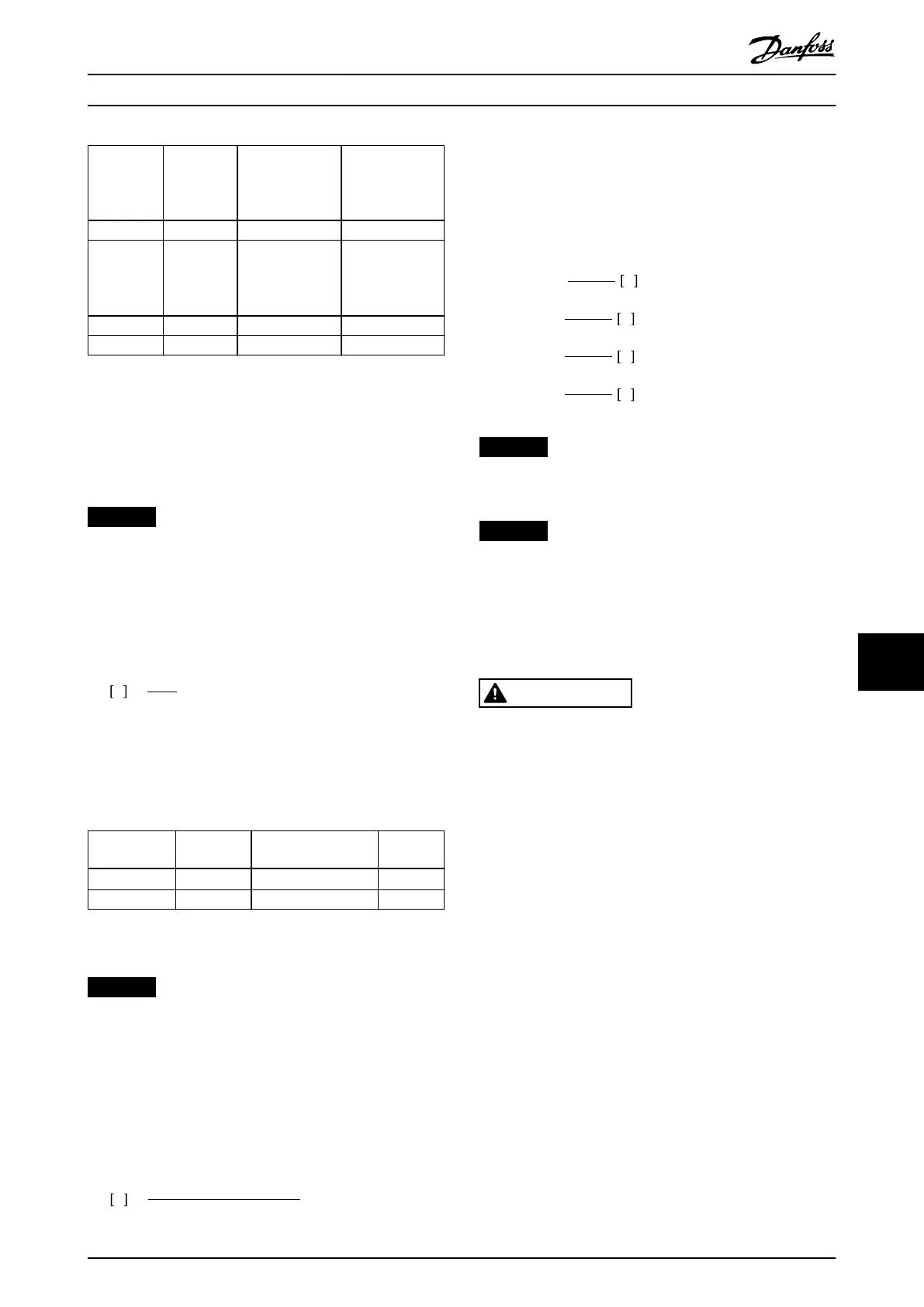

380–480 V

Model

Cycle time

(s)

Braking duty

cycle at 100%

torque

Braking duty

cycle at over

torque

(150/160%)

P355–P1000 600 40% 10%

525–690

Model

Cycle time

(s)

Braking duty

cycle at 100%

torque

Braking duty

cycle at over

torque

(150/160%)

P560–P630 600 40% 10%

P710–P1M4 600 40% 10%

Table 10.34 Braking at High Overload Torque Level

Danfoss oers brake resistors with duty cycle of 5%, 10%,

and 40%. If a 10% duty cycle is applied, the brake resistors

are able to absorb brake power for 10% of the cycle time.

The remaining 90% of the cycle time is used to dissipate

excess heat.

NOTICE

Make sure that the resistor is designed to handle the

required braking time.

The maximum allowed load on the brake resistor is stated

as a peak power at a given intermittent duty cycle. The

brake resistance is calculated as shown:

R

br

Ω =

U

dc

2

P

peak

where

P

peak

=P

motor

xM

br

[%]xη

motor

xη

VLT

[W]

As can be seen, the brake resistance depends on the DC-

link voltage (U

dc

).

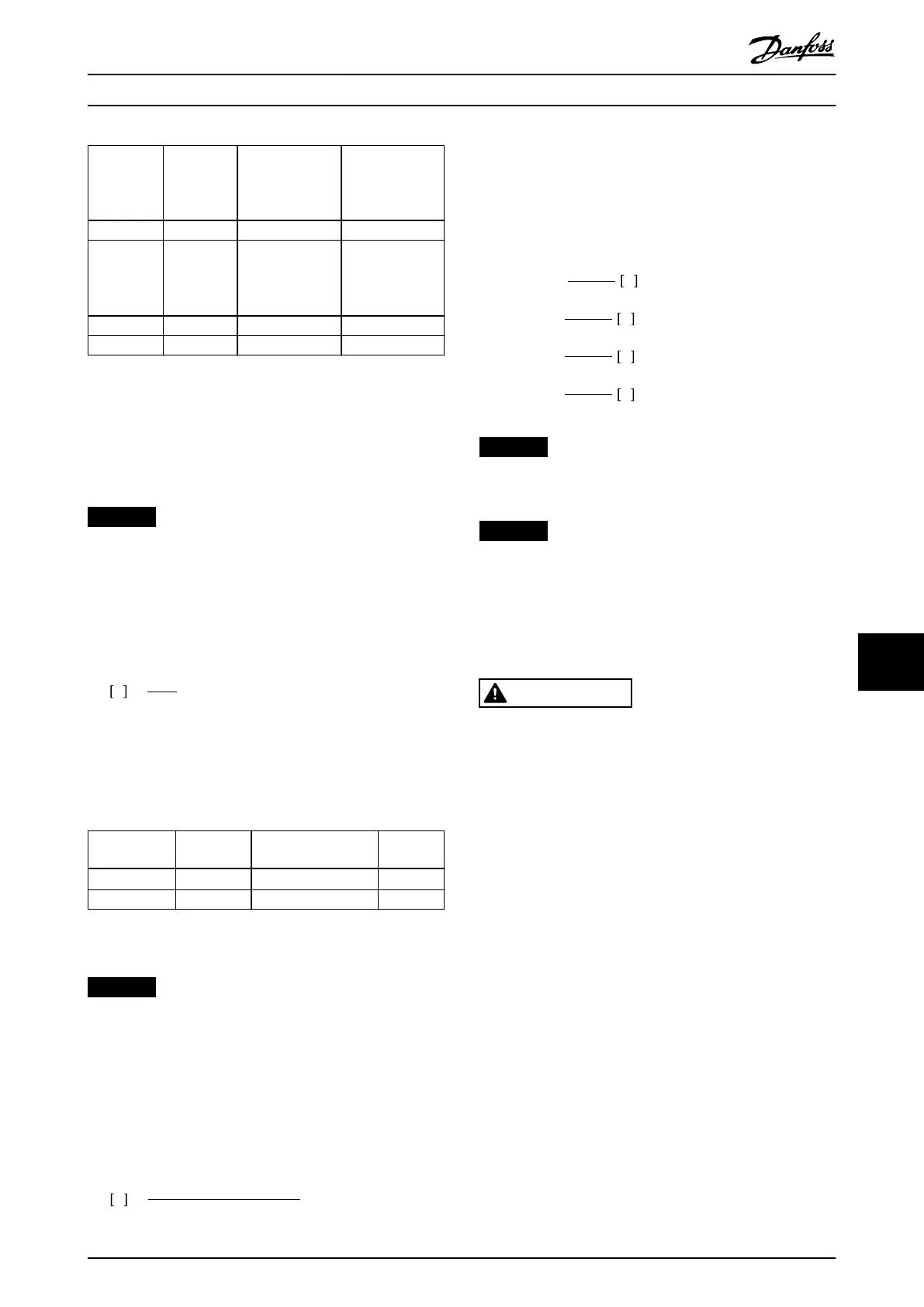

Size Brake

active

Warning before

cutout

Cutout

(trip)

380–480 V

1)

810 V 828 V 855 V

525–690 V 1084 V 1109 V 1130 V

Table 10.35 FC 102/FC 202 Brake Limits

1) Power size dependent

NOTICE

Check that the brake resistor can handle a voltage of

410 V, 820 V, 850 V, 975 V, or 1130 V. Danfoss brake

resistors are rated for use on all Danfoss drives.

Danfoss recommends the brake resistance R

rec

. This

calculation guarantees that the drive is able to brake at the

highest brake power (M

br(%)

) of 150%. The formula can be

written as:

R

rec

Ω =

U

dc

2

x100

P

motor

xM

br( % )

xη

VLT

xη

motor

η

motor

is typically at 0.90

η

VLT

is typically at 0.98

For 200 V, 480 V, 500 V, and 600 V drives, R

rec

at 160%

brake power is written as:

200V:R

rec

=

107780

P

motor

Ω

500V:R

rec

=

464923

P

motor

Ω

600V:R

rec

=

630137

P

motor

Ω

690V:R

rec

=

832664

P

motor

Ω

NOTICE

The resistor brake circuit resistance selected should not

be higher than what Danfoss recommends.

NOTICE

If a short circuit occurs in the brake transistor, power

dissipation in the brake resistor is prevented only by

using a mains switch or contactor to disconnect the

mains from the drive, or a contact in the brake circuit.

Uninterrupted power dissipation in the brake resistor can

cause overheating, damage, or a re.

WARNING

FIRE HAZARD

Brake resistors get hot during and after braking. Failure

to place the brake resistor in a secure area can result in

property damage and/or serious injury.

•

Ensure that the brake resistor is placed in a

secure environment to avoid re risk.

•

Do not touch the brake resistor during or after

braking to avoid serious burns.

10.8.2 Control with Brake Function

A relay/digital output can be used to protect the brake

resistor against overloading or overheating by generating a

fault in the drive. If the brake IGBT is overloaded or

overheated, the relay/digital signal from the brake to the

drive turns o the brake IGBT. This relay/digital signal does

not protect against a short circuit in the brake IGBT or a

ground fault in the brake module or wiring. If a short

circuit occurs in the brake IGBT, Danfoss recommends a

means to disconnect the brake.

In addition, the brake makes it possible to read out the

momentary power and the average power for the latest

120 s. The brake can monitor the power energizing and

make sure that it does not exceed the limit selected in

Electrical Installation Con... Design Guide

MG16C302 Danfoss A/S © 11/2017 All rights reserved. 187

10 10

Loading...

Loading...