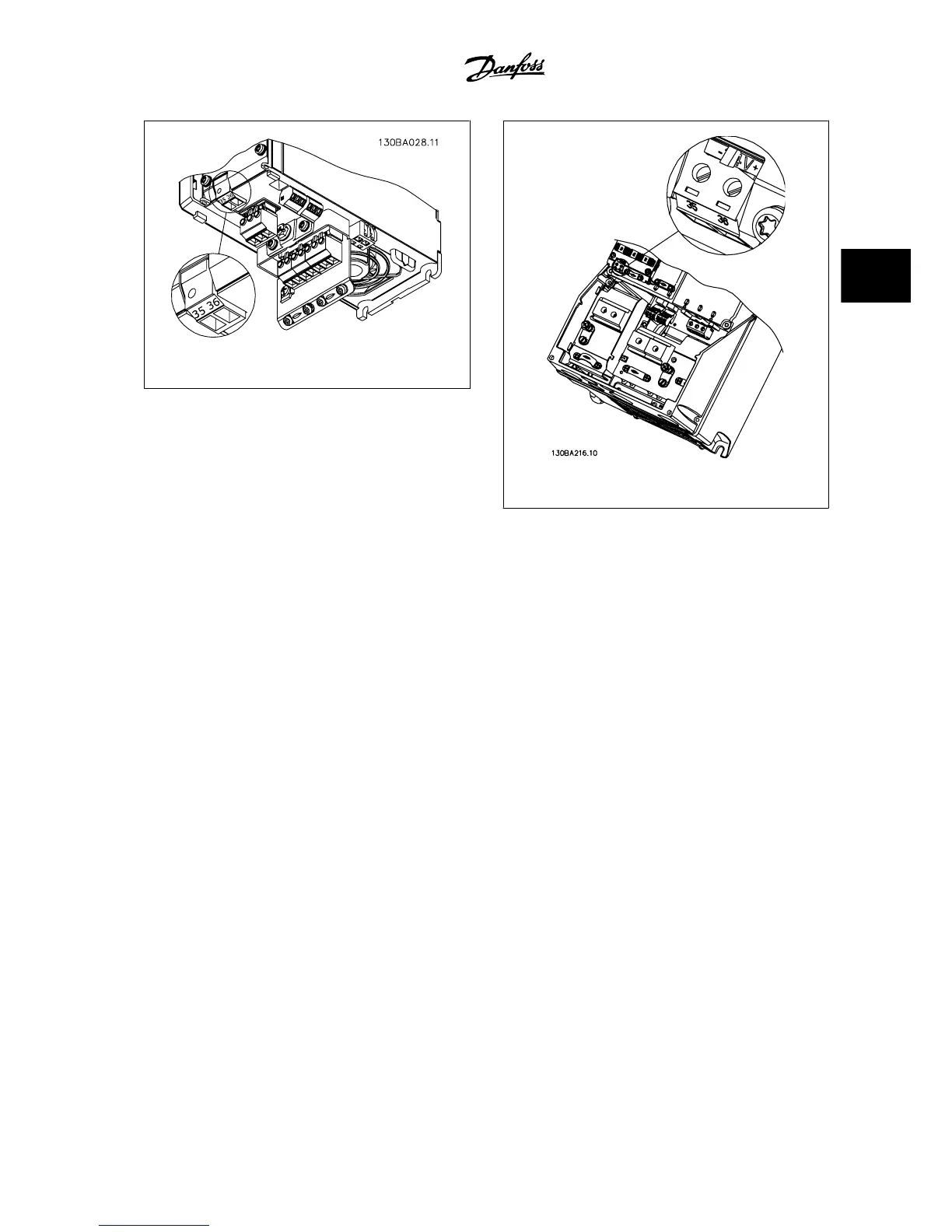

Figure 3.21: Connection to 24 V back-up supplier (A2-A3).

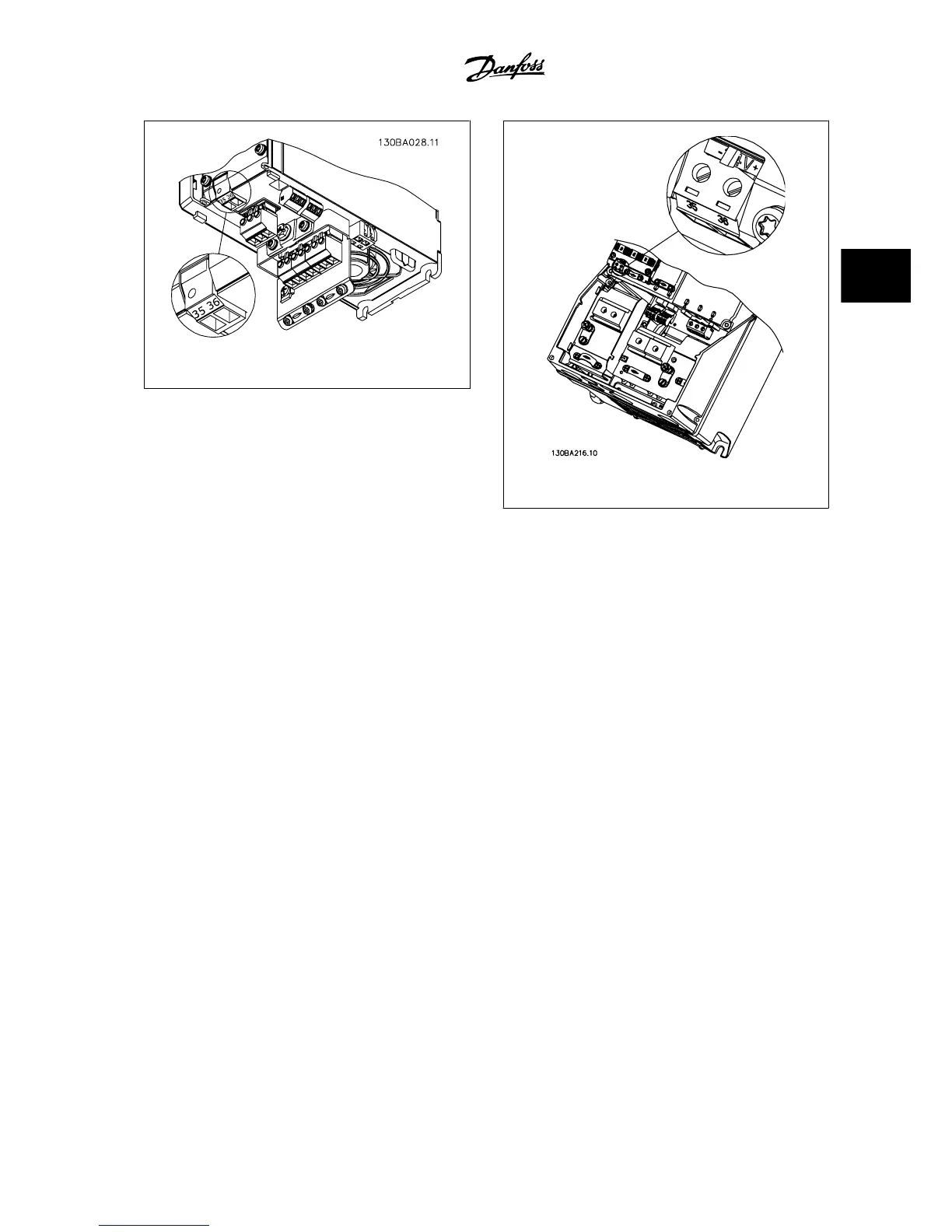

Figure 3.22: Connection to 24 V back-up supplier (A5-C2).

3.6.9 Analog I/O option MCB 109OPCAIO Analog I/O Option Module

The analog I/O card is supposed to be used in e.g., the following cases:

• Providing battery back-up of clock function on control card

• As general extension of analog I/O selection available on control card, e.g., for multi-zone control with three pressure transmitters

• Turning the adjustable frequency drive into a de-central I/O block supporting a Building Management System with inputs for sensors and outputs

for operating dampers and valve servos

• Support extended PID controllers with I/Os for setpoint inputs, transmitter/sensor inputs and outputs for switches.

VLT

®

AQUA Drive Design Guide 3 VLT AQUA Selection

MG.20.N5.22 - VLT

®

is a registered Danfoss trademark

3-37

3

Loading...

Loading...