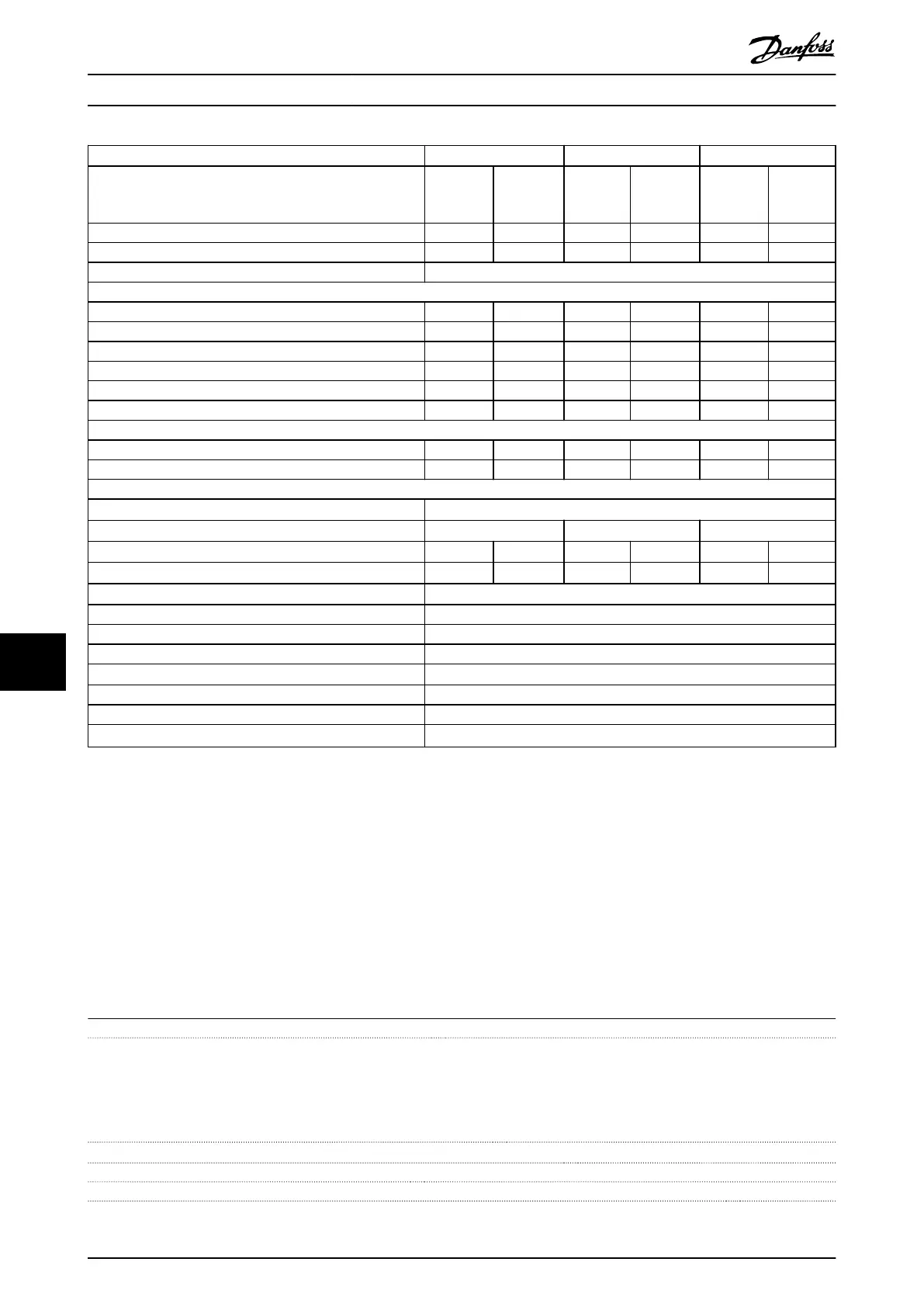

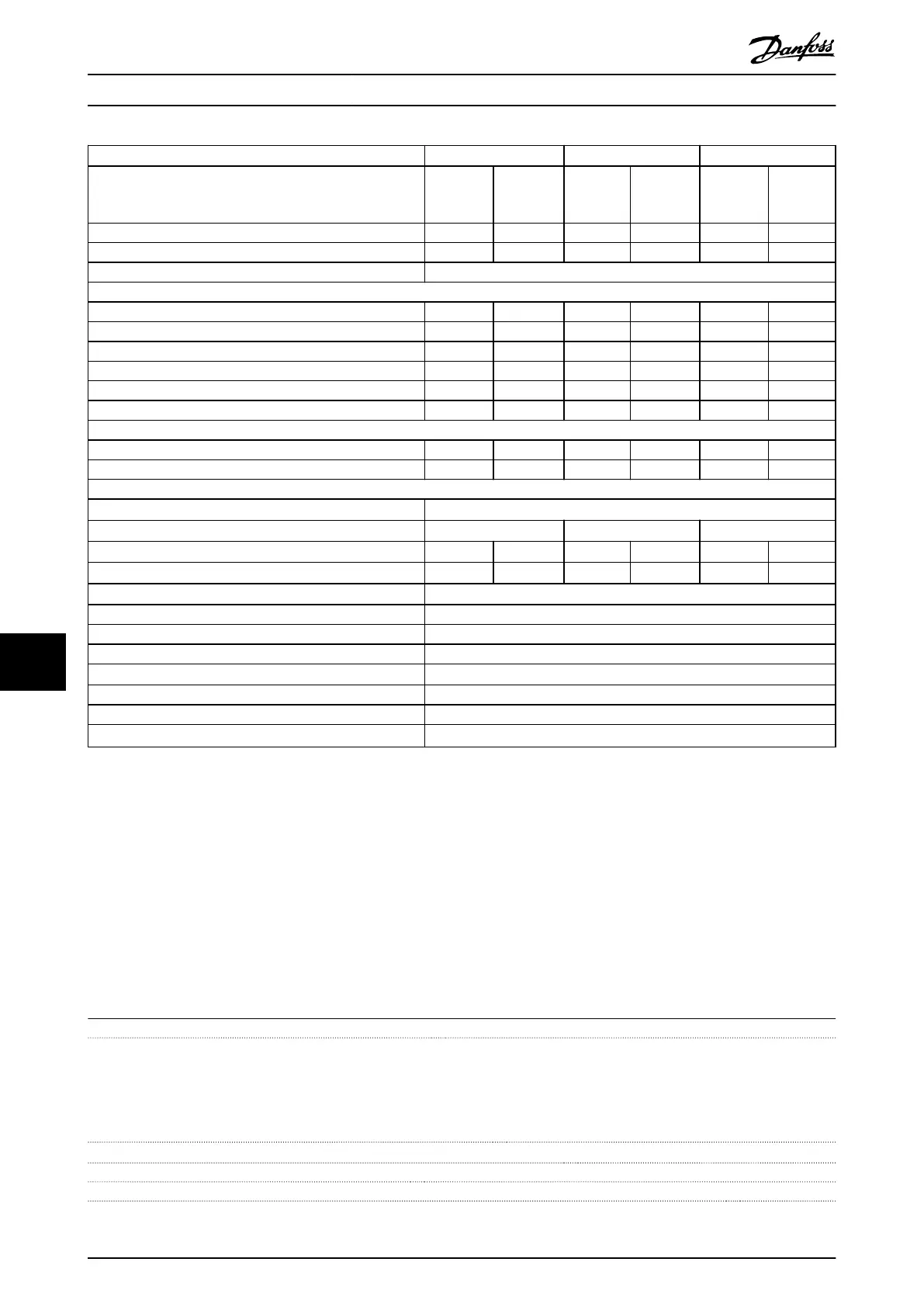

VLT

®

AutomationDrive FC 361

N200 N250 N315

High/normal overload HO NO HO NO HO NO

(High overload=150% current during 60 s, normal

overload=110% current during 60 s)

Typical shaft output at 400 V [kW] 160 200 200 250 250 315

Typical shaft output at 460 V [hp] 250 300 300 350 350 450

Enclosure size J9

Output current (3-phase)

Continuous (at 400 V) [A] 315 395 395 480 480 588

Intermittent (60 s overload) (at 400 V)[A] 473 435 593 528 720 647

Continuous (at 460 V) [A] 302 361 361 443 443 535

Intermittent (60 s overload) (at 460 V) [kVA] 453 397 542 487 665 589

Continuous kVA (at 400 V) [kVA] 218 274 274 333 333 407

Continuous kVA (at 460 V) [kVA] 241 288 288 353 353 426

Maximum input current

Continuous (at 400 V) [A] 304 381 381 463 463 567

Continuous (at 460 V) [A] 291 348 348 427 427 516

Maximum number and size of cables per phase

Mains, motor, brake, and load share [mm

2

(AWG)]

2x185 (2x350 mcm)

Maximum external mains fuses [A]

1)

550 630 800

Estimated power loss at 400 V [W]

2), 3)

3093 4116 4039 5137 5004 6674

Estimated power loss at 460 V [W]

2), 3)

2872 3569 3575 4566 4458 5714

Eciency

3)

0.98

Output frequency [Hz] 0–590

Heat sink overtemperature trip [°C (°F)]

110 (230)

Weight, enclosure protection rating IP20 kg (lbs) 168.6 (371.6)

Eciency

3)

0.98

Output frequency [Hz] 0–590

Heat sink overtemperature trip [°C (°F)]

110 (230)

Control card overtemperature trip [°C (°F)]

80 (176)

Table 10.2 Electrical Data for Enclosures J9, Mains Supply 3x380–480 V AC

1) For fuse ratings, see chapter 10.7 Fuses and Circuit Breakers.

2) Typical power loss is at normal conditions and expected to be within

±

15% (tolerance relates to variety in voltage and cable conditions). These

values are based on a typical motor eciency (IE/IE3 border line). Lower eciency motors add to the power loss in the drive. Applies for

dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses can increase. LCP and typical control

card power consumptions are included. For power loss data according to EN 50598-2, refer to drives.danfoss.com/knowledge-center/energy-

eciency-directive/#/. Options and customer load can add up to 30 W to the losses, though usually a fully loaded control card and options for

slots A and B each add only 4 W.

3) Measured using 5 m (16.4 ft) shielded motor cables at rated load and rated frequency. Eciency measured at nominal current. For energy

eciency class, see chapter 10.4 Ambient Conditions. For part load losses, see drives.danfoss.com/knowledge-center/energy-eciency-directive/#/.

10.2

Mains Supply

Mains supply (L1, L2, L3)

Supply voltage 380–480 V ±10%

Mains voltage low/mains voltage drop-out:

During low mains voltage or a mains drop-out, the drive continues until the DC-link voltage drops below the minimum stop

level, which corresponds typically to 15% below the lowest rated supply voltage of the drive. Power-up and full torque cannot be

expected at mains voltage lower than 10% below the lowest rated supply voltage of the drive.

Supply frequency 50/60 Hz ±5%

Maximum imbalance temporary between mains phases 3.0% of rated supply voltage

1)

True power factor (λ) ≥0.9 nominal at rated load

Displacement power factor (cos Φ) near unity (>0.98)

Specications VLT® AutomationDrive FC 361

58 Danfoss A/S © 06/2018 All rights reserved. MG06I102

1010

Loading...

Loading...