The drive uses back-channel cooling to circulate the heat

sink cooling air. The cooling duct can carries approximately

90% of the heat out of the back channel of the drive.

Redirect the back-channel air from the panel or room by

using:

•

Duct cooling. Back-channel cooling kits are

available to direct the air away from the panel

when an IP20/chassis drive is installed in a Rittal

enclosure. Use of a kit reduces the heat in the

panel and smaller door fans can be specied on

the enclosure.

•

Cooling out the back (top and base covers). The

back-channel cooling air can be ventilated out of

the room so that the heat from the back channel

is not dissipated into the control room.

NOTICE

One or more door fans are required on the enclosure to

remove heat not contained in the back channel of the

drive. The fans also remove any additional losses

generated by other components inside the drive.

Ensure that the fans supply adequate airow over the heat

sink. To select the appropriate number of fans, calculate

the total required airow. The ow rate is shown in

Table 4.2.

Enclosure size Door fan/top fan Heat sink fan

J8

102 m

3

/hr (60 CFM) 420 m

3

/hr (250 CFM)

J9

204 m

3

/hr (120 CFM) 840 m

3

/hr (500 CFM)

Table 4.2 Airow

4.6

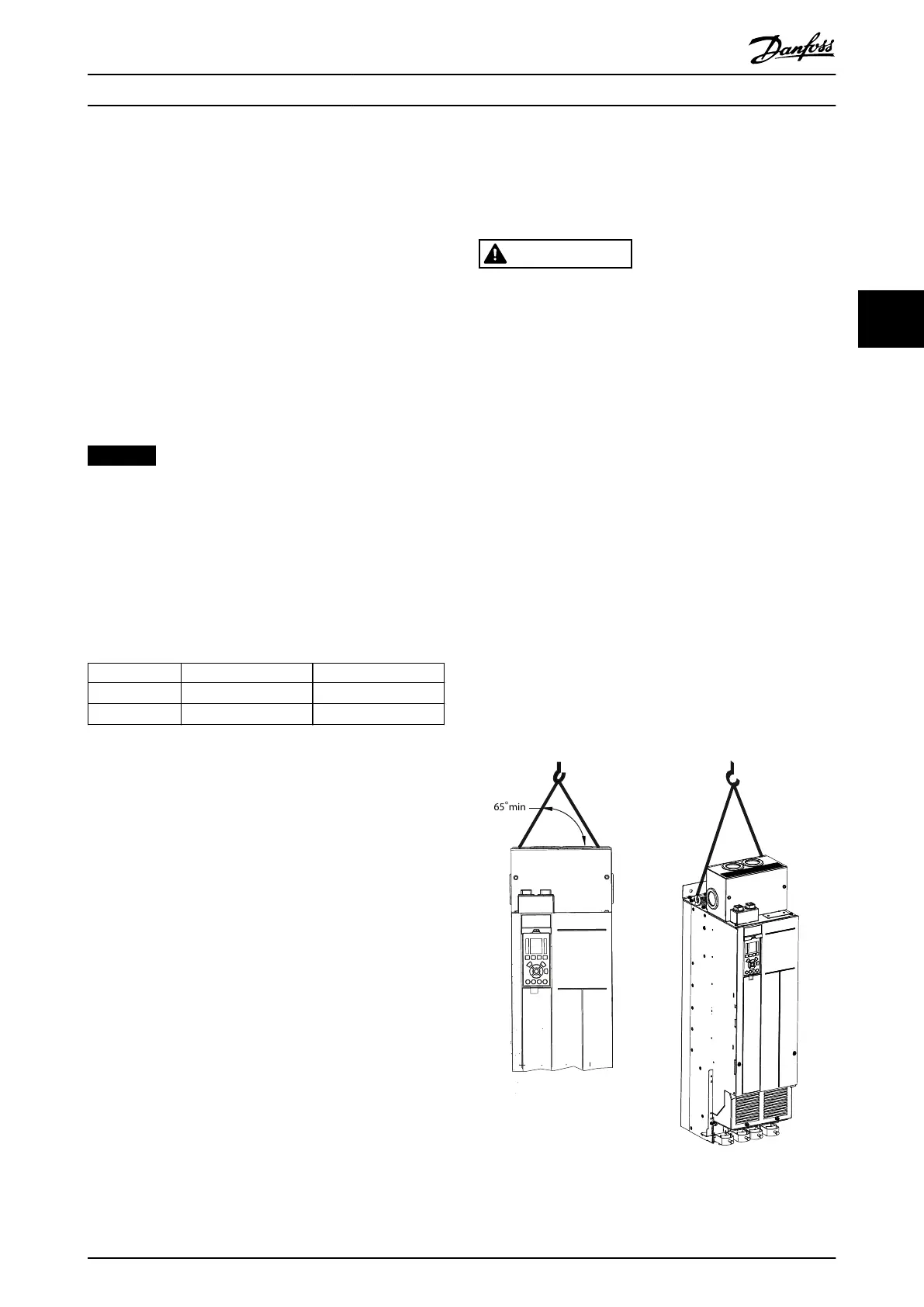

Lifting the Drive

Always lift the drive using the dedicated eye bolts at the

top of the drive. See Illustration 4.2.

WARNING

HEAVY LOAD

Unbalanced loads can fall or tip over. Failure to take

proper lifting precautions increases risk of death, serious

injury, or equipment damage.

•

Move the unit using a hoist, crane, forklift, or

other lifting device with the appropriate weight

rating. See chapter 3.2 Power Ratings, Weights,

and Dimensions for the weight of the drive.

•

Failure to locate the center of gravity and

correctly position the load can cause

unexpected shifting during lifting and

transport. For measurements and center of

gravity, see chapter 10.9 Enclosure Dimensions.

•

The angle from the top of the drive module to

the lifting cables aects the maximum load

force on the cable. This angle must be 65° or

greater. Refer to Illustration 4.2. Attach and

dimension the lifting cables properly.

•

Never walk under suspended loads.

•

To guard against injury, wear personal

protective equipment such as gloves, safety

glasses, and safety shoes.

Illustration 4.2 Lifting the Drive

Mechanical Installation Operating Guide

MG06I102 Danfoss A/S © 06/2018 All rights reserved. 15

4 4

Loading...

Loading...