4 Mechanical Installation

4.1 Items Supplied

Items supplied may vary according to product congu-

ration.

•

Make sure the items supplied and the information

on the nameplate correspond to the order conr-

mation.

•

Check the packaging and the drive visually for

damage caused by inappropriate handling during

shipment. File any claim for damage with the

carrier. Retain damaged parts for clarication.

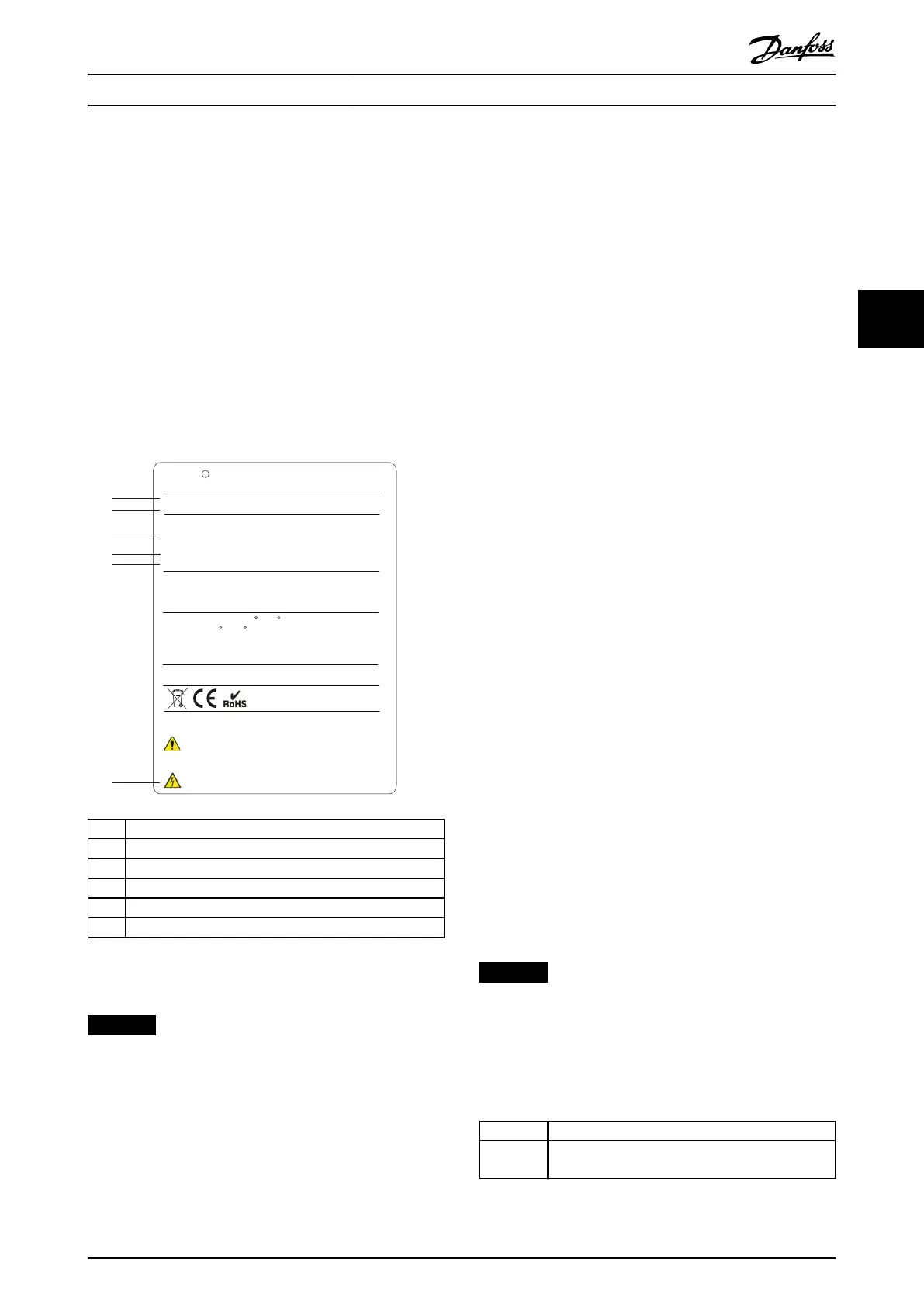

OUT: 3x0-Vin 0-590Hz 212/190 A

IN: 3x380-480 V 50/60Hz 204/183 A

110 kW / 150 HP, High Overload

OUT: 3x0-Vir. 0-590Hz 260/240 A

132 kW / 200 HP, Normal Overload

VLT

T/C: FC-361N132T4E20H2RXCXXXSXXXXAXBX

P/N: 136G8270 S/N:

123456H123

R

AutomationDrive

www.danfoss.com

e30bg567.10

IN: 3x380-480V 50/60Hz 251/231 A

ASSEMBLED IN USA

Max Tamb. 55

C/131

F w/Output Current Derating

CHASSIS/IP20 Tamb. 45 C/113 F

CAUTION - ATTENTION:

Stored charge, wait 20 min.

Charge residuelle, attendez 20 min.

See manual for special condition / mains fuse

Voir manuel de conditions speciales / fusibles

WARNING - AVERTISSEMENT:

`

`

1

2

3

4

5

6

Danfoss A/S

6340 Nordborg

Denmark

1 Type code

2 Part number and serial number

3 Power rating

4 Input voltage, frequency, and current

5 Output voltage, frequency, and current

6 Discharge time

Illustration 4.1 Example Nameplate for Drive Only (J8–J9)

NOTICE

LOSS OF WARRANTY

Do not remove the nameplate from the drive. Removing

the nameplate can result in loss of warranty.

4.2 Tools Needed

Receiving/unloading

•

I-beam and hooks rated to lift the weight of the

drive. Refer to chapter 3.2 Power Ratings, Weights,

and Dimensions.

•

Crane or other lifting aid to place the unit into

position.

Installation

•

Drill with 10 mm (0.39 in) or 12 mm (0.47 in) drill

bits.

•

Tape measurer.

•

Various sizes of Phillips and at bladed

screwdrivers.

•

Wrench with relevant metric sockets (7–17 mm/

0.28–0.67 in).

•

Wrench extensions.

•

Torx drives (T25 and T50).

•

Sheet metal punch for conduits or cable glands.

•

I-beam and hooks to lift the weight of the drive.

Refer to chapter 3.2 Power Ratings, Weights, and

Dimensions.

•

Crane or other lifting aid to place the drive onto

pedestal and into position.

4.3

Storage

Store the drive in a dry location. Keep the equipment

sealed in its packaging until installation. Refer to

chapter 10.4 Ambient Conditions for recommended ambient

temperature.

Periodic forming (capacitor charging) is not necessary

during storage unless storage exceeds 12 months.

4.4

Operating Environment

NOTICE

In environments with airborne liquids, particles, or

corrosive gases, ensure that the IP/type rating of the

equipment matches the installation environment. Failure

to meet requirements for ambient conditions can reduce

the lifetime of the drive. Ensure that requirements for air

humidity, temperature, and altitude are met.

Voltage [V] Altitude restrictions

380–480 At altitudes above 3000 m (9842 ft), contact

Danfoss regarding PELV.

Table 4.1 Installation at High Altitudes

Mechanical Installation Operating Guide

MG06I102 Danfoss A/S © 06/2018 All rights reserved. 13

4 4

Loading...

Loading...