1. Use a clamp from the accessory bag

to connect the shield to the adjusta-

ble frequency drive decoupling plate

for control cables.

See section entitled

Grounding of Shielded/

Armored Control Cables

for the correct termi-

nation of control cables.

Illustration 4.29: Control cable clamp.

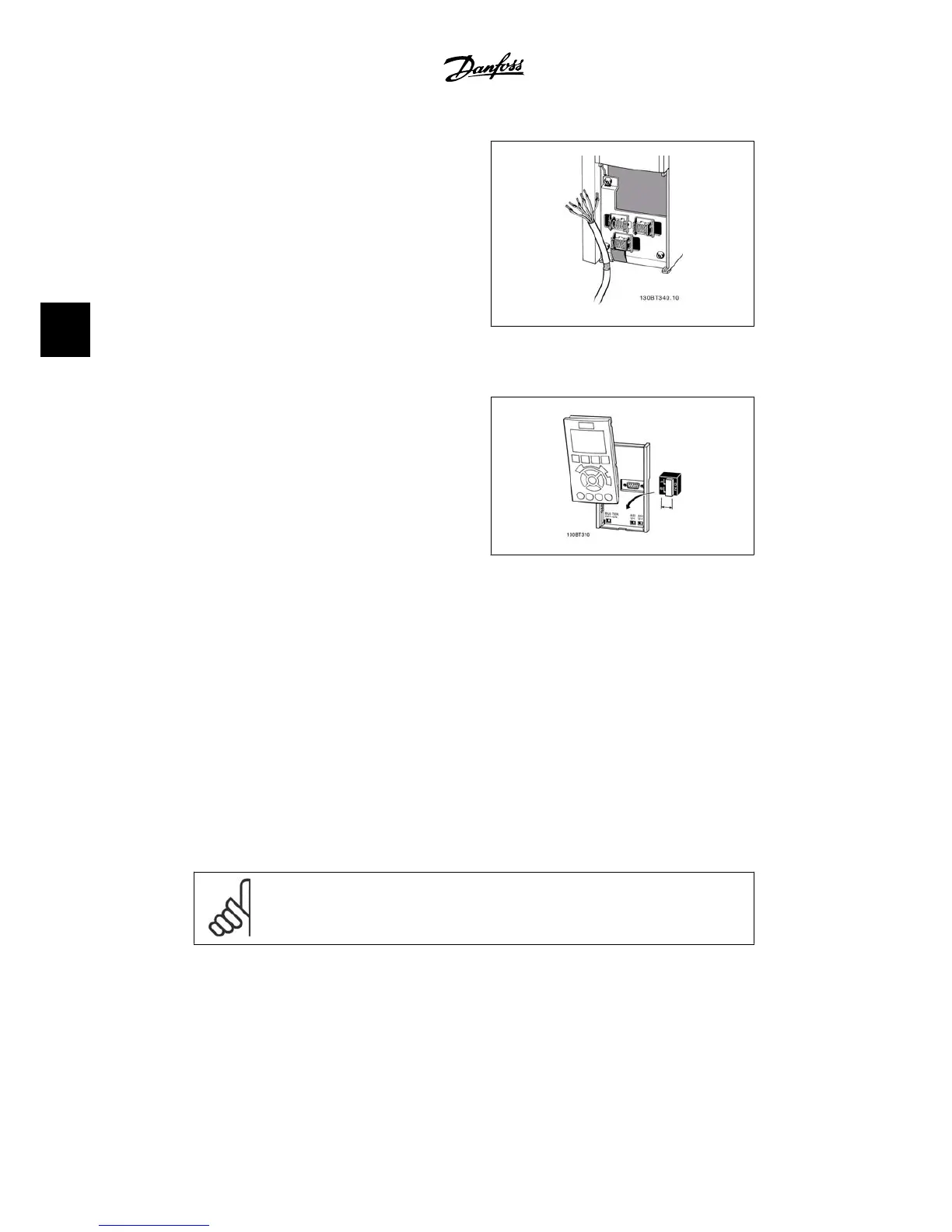

4.1.20. Switches S201, S202, and S801

Switches S201 (Al 53) and S202 (Al 54) are

used to select a current (0-20 mA) or a voltage

(0 to 10 V) configuration of the analog input

terminals 53 and 54 respectively.

Switch S801 (BUS TER.) can be used to enable

termination on the RS-485 port (terminals 68

and 69).

Please note that the switches may be covered

by an option, if so equipped.

Default setting:

S201 (AI 53) = OFF (voltage input)

S202 (AI 54) = OFF (voltage input)

S801 (Bus termination) = OFF

Illustration 4.30: Switches location.

4.2. Final optimization and test

4.2.1. Final optimization and test

To optimize motor shaft performance and optimize the adjustable frequency drive for the con-

nected motor and installation, please follow these steps: Ensure that adjustable frequency

driverand motor are connected and that power is applied to adjustable frequency drive.

NOTE

Before power-up, ensure that connected equipment is ready for use.

Step 1. Locate motor nameplate

4. Electrical installation VLT

®

HVAC Drive Instruction Manual

46

MG.11.A4.22 - VLT

®

is a registered Danfoss trademark

4

Loading...

Loading...