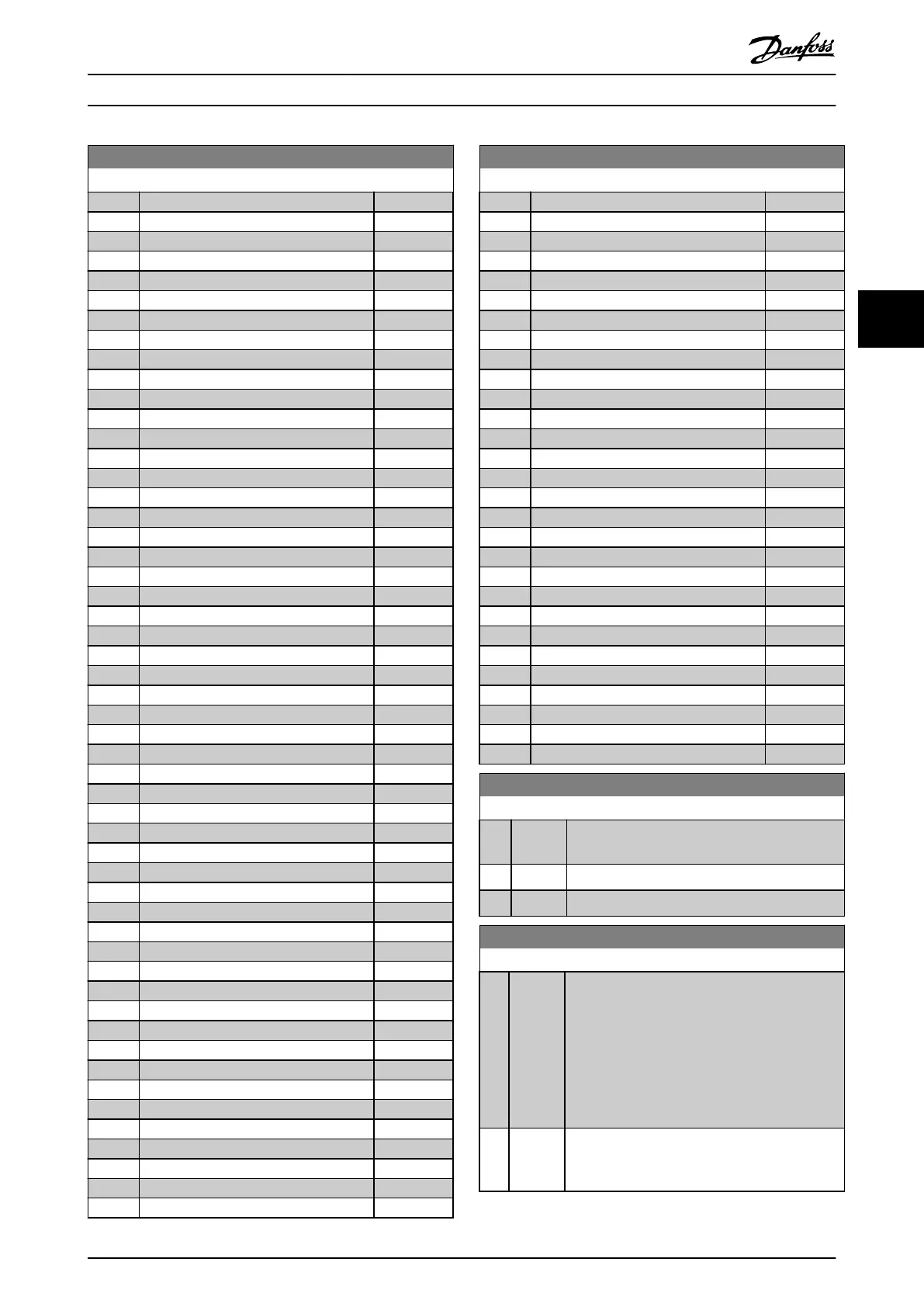

9-23 Parameters for Signals

Option: Function:

[615] Terminal 53 High Ref./Feedb. Value

[625] Terminal 54 High Ref./Feedb. Value

[696] Terminal 42 Output Bus Control

[748] PCD Feed Forward

[890] Bus Jog 1 Speed

[891] Bus Jog 2 Speed

[1500] Operating hours

[1501] Running Hours

[1502] kWh Counter

[1600] Control Word

[1601] Reference [Unit]

[1602] Reference [%]

[1603] Status Word

[1605] Main Actual Value [%]

[1609] Custom Readout

[1610] Power [kW]

[1611] Power [hp]

[1612] Motor Voltage

[1613] Frequency

[1614] Motor current

[1615] Frequency [%]

[1616] Torque [Nm]

[1618] Motor Thermal

[1620] Motor Angle

[1622] Torque [%]

[1630] DC Link Voltage

[1633] Brake Energy /2 min

[1634] Heatsink Temp.

[1635] Inverter Thermal

[1638] SL Controller State

[1639] Control Card Temp.

[1650] External Reference

[1652] Feedback[Unit]

[1653] Digi Pot Reference

[1657] Feedback [RPM]

[1660] Digital Input

[1661] Terminal 53 Setting

[1662] Analog Input 53

[1663] Terminal 54 Setting

[1664] Analog Input AI54

[1665] Analog Output 42 [mA]

[1667] Pulse Input 29[Hz]

[1668] Pulse Input 33 [Hz]

[1669] Pulse Output 27 [Hz]

[1671] Relay Output

[1672] Counter A

[1673] Counter B

[1674] Prec. Stop Counter

[1680] Fieldbus CTW 1

[1682] Fieldbus REF 1

[1684] Comm. Option STW

[1685] FC Port CTW 1

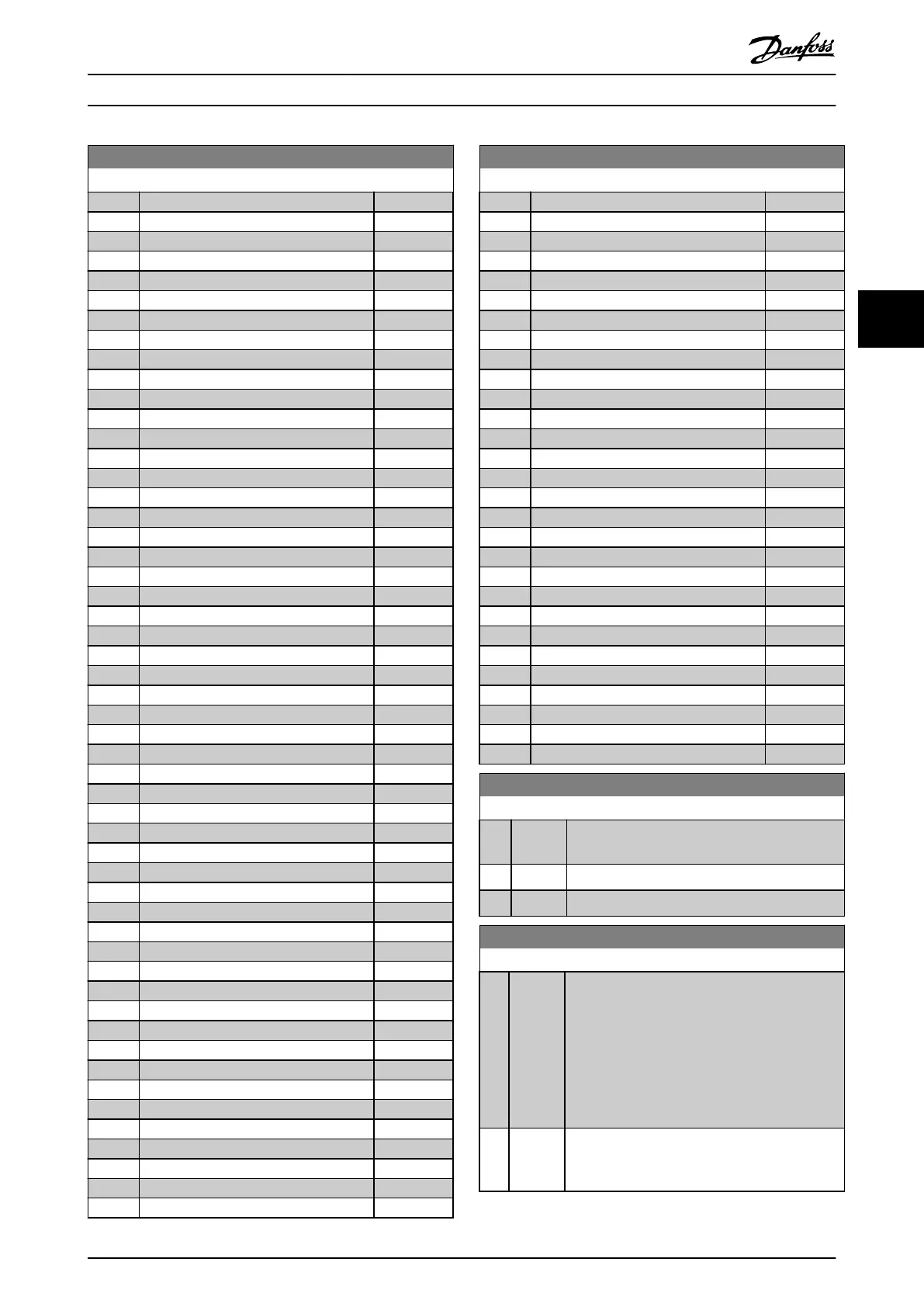

9-23 Parameters for Signals

Option: Function:

[1690] Alarm Word

[1691] Alarm Word 2

[1692] Warning Word

[1693] Warning Word 2

[1694] Ext. Status Word

[1695] Ext. Status Word 2

[1697] Alarm Word 3

[3401] PCD 1 Write For Application

[3402] PCD 2 Write For Application

[3403] PCD 3 Write For Application

[3404] PCD 4 Write For Application

[3405] PCD 5 Write For Application

[3406] PCD 6 Write For Application

[3407] PCD 7 Write For Application

[3408] PCD 8 Write For Application

[3409] PCD 9 Write For Application

[3410] PCD 10 Write For Application

[3421] PCD 1 Read For Application

[3422] PCD 2 Read For Application

[3423] PCD 3 Read For Application

[3424] PCD 4 Read For Application

[3425] PCD 5 Read For Application

[3426] PCD 6 Read For Application

[3427] PCD 7 Read For Application

[3428] PCD 8 Read For Application

[3429] PCD 9 Read For Application

[3430] PCD 10 Read For Application

[3450] Actual Position

[3456] Track Error

9-27 Parameter Edit

Option: Function:

Parameters can be edited via PROFIBUS, the

standard RS485 interface, or the LCP.

[0] Disabled Disables editing via PROFIBUS.

[1] * Enabled Enables editing via PROFIBUS.

9-28 Process Control

Option: Function:

Process control (setting of control word, speed

reference, and process data) is possible via either

PROFIBUS or standard eldbus, but not both

simultaneously. Local control is always possible via

the LCP. Control via process control is possible via

either terminals or eldbus depending on the

settings in parameter 8-50 Coasting Select to

parameter 8-56 Preset Reference Select.

[0] Disable Disables process control via PROFIBUS master

class 1 and enables process control via standard

eldbus or PROFIBUS master class 2.

Parameter Descriptions Programming Guide

MG07C102 Danfoss A/S © 12/2015 All rights reserved. 77

4 4

Loading...

Loading...