Shaft assembly

The Shaft arrangement is largely

maintenance-free. Even the external rubber

cutlass bearing is water-lubricated. Running

it dry will quickly destroy it. See the VOLVO

service sheet for instructions on how to vent

and lubricate the shaft seal (see also Page

6 of this manual).

In addition to the servicing instructions

given in the YANMAR manual, the shaft

arrangement must also be re-aligned after

20 hours’ operation. Chapter 3, “Installation

of the engine” describes how this is done.

The last section in the YANMAR operating

instructions, deals with the centring of the

propeller shaft after 50 hours. This point is

often forgotten. The procedure for checking

this is simple: undo the coupling flange and

check the clearance with a feeler gauge.

The flange should not be more than 3/10

out of alignment. The heavy Centraflex

shaft coupling is not held by the VOLVO

shaft seal and must be supported

accordingly. Take up sufficient thread on

the stay bolts of the rear engine bearers to

raise the rear of the engine, which usually

sags, back up again. (see diagram in Fig.

33)

Careful alignment of the engine installation

will keep noise level to a minimum.

The zinc anode on the propeller shaft is a

wasting component and should be replaced

once a year. It should be fitted so as to

ensure good electrical connection between

the shaft and the inside surface of the

anode.

In the Mediterranean, it has proved

expedient to paint the propeller shaft and

folding propeller with toxic paint. Under no

circumstances paint the zinc anode, as this

will impair its effectiveness.

Folding Propeller

Folding Propellers have to be serviced

annually, the double socket head cap

screws inspected to ensure they are

secure, and the propeller greased. This job

is best done during winter lay up.

Included in the technical documentation

supplied with the boat is an illustrated

servicing sheet provided by the

manufacturer.

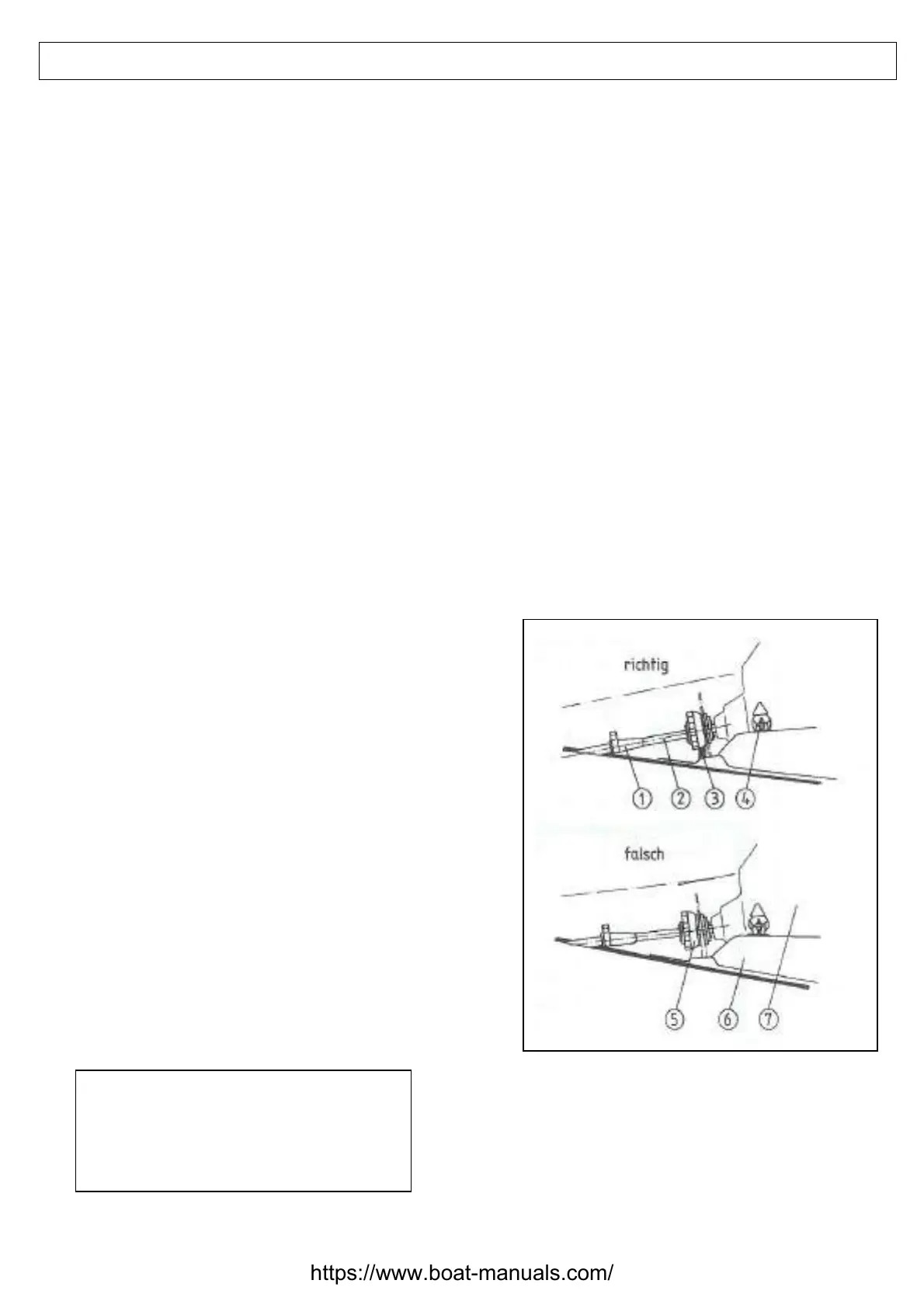

Fig. 33 Centring of the propeller shaft

1. VOLVO shaft seal

2. Propeller shaft

3. Chock

4. Engine Bearer with adjusting bolt

5. Shaft coupling

6. Engine Bed

7. Engine

The zinc anode should be sanded

back to bright metal or replaced, if

ever the boat is hauled out for repairs

32

https://www.boat-manuals.com/

Loading...

Loading...