The circuit diagram shows the distribution

bridges and electrical junctions that have to be

checked first. The cable ends are different

colours (see circuit diagram on Pages 38-39).

When disconnecting a load, unclamp the

battery negative pole. Some switches and

cables are left exposed.

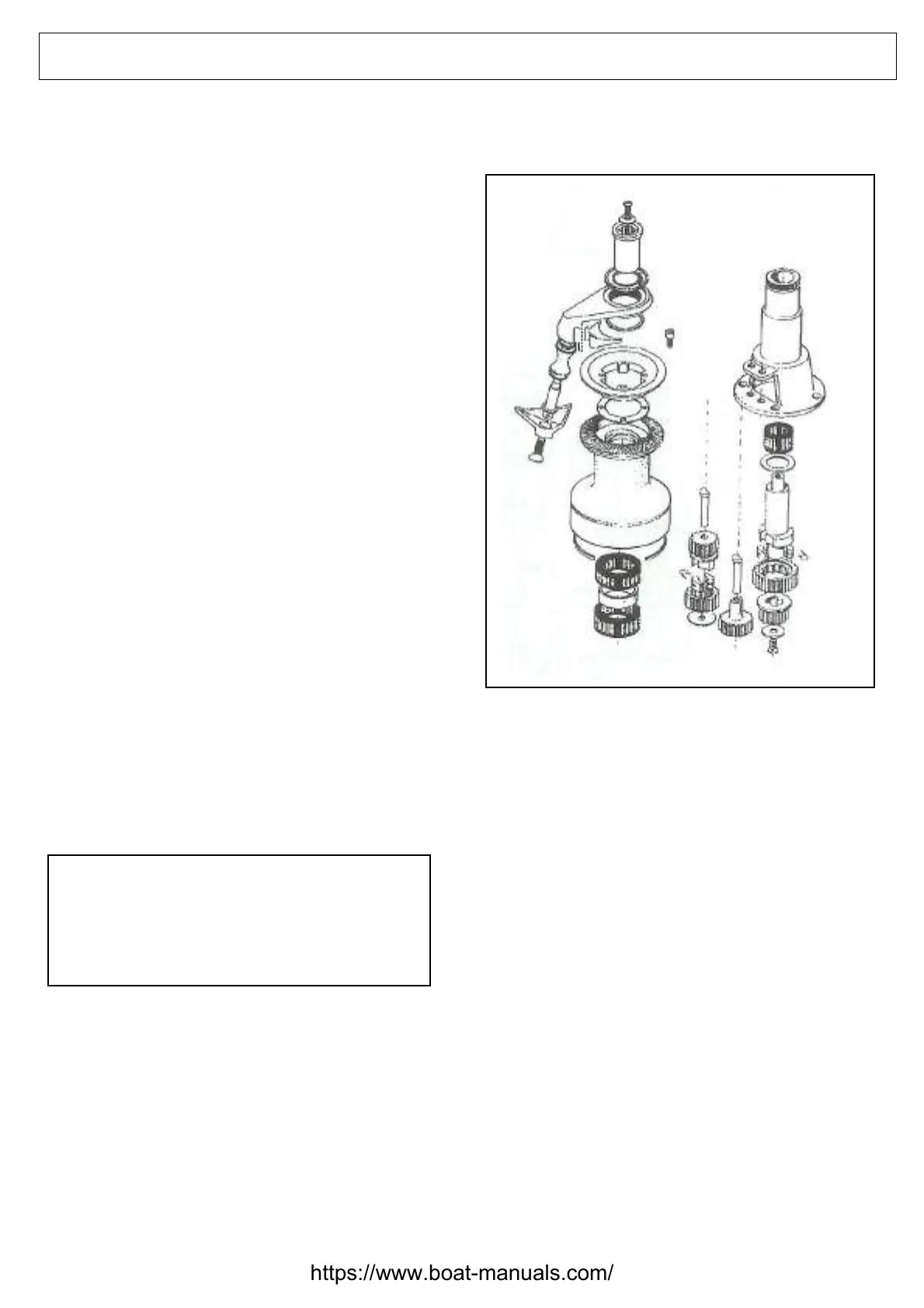

Servicing the winches

The modern HARKEN winches are of a

simple, robust design. Nevertheless, the

bearings will need to be re-greased at least

once a year. Grease that has turned to resin

can only have an adverse effect on the

functioning of the winch. Disassembly and

reassembly of the winches is as follows:

Remove the securing screw with a large

screwdriver and then remove the entire head

and self-tailing mechanism from the winch

base.

Make sure that the detent pawls do not spring

out, and that the pawl springs are correctly

seated on reassembly.

The documentation supplied should include

two A4 sheets in English, containing an

exploded drawing of the winch construction.

The method of cleaning the winch is described

in the diagrams on the back.

Fig. 42. Winch

Autopilot

If the boat is equipped with an autopilot, then it

is soon given a name and regarded as an extra

member of the crew. The autopilot is

unbeatable, in terms of stamina and

concentration.

Please familiarize yourself thoroughly with the

operating instructions. Apart from the control

panel, virtually all the components of the

AUTOHELM ST 6000 have been fitted with the

computer in the space below the steering

pedestal, comprising the Linear Drive,

Repeater, Gyro-plus Sensor and Computer.

Access to these components can be gained by

opening the hatch at the foot of the after cabin.

The Fluxgate Compass is mounted on the

bulkhead in the washroom/toilet compartment.

A small paintbrush dipped in petroleum or

benzene will make the job of cleaning the

winch components easier.

Dehler 35 cws

42

https://www.boat-manuals.com/

Loading...

Loading...