Chapter 7 Optional AccessoriesC2000 Plus

7-6

*2. Refer to Chapter 7 “Brake Module and Brake Resistors” in the application manual for “Operation Duration & ED” vs. “Braking

Current”.

*3. To dissipate heat, mount a resistors of 400 W or lower to a frame to keep the surface temperature below 250°C. Fix a resistor of

1000 W or higher to a surface to keep the surface temperature below 350°C. (If the surface temperature is higher than the

temperature limit, install extra cooling or increase the size of the resistor.)

*4. The calculation of the brake resistor is based on a four-pole motor (1800 rpm). Refer to VFDB series Braking Module

Instruction for more details on brake resistor.

NOTE:

1. Specification and Appearance of Brake Resistors

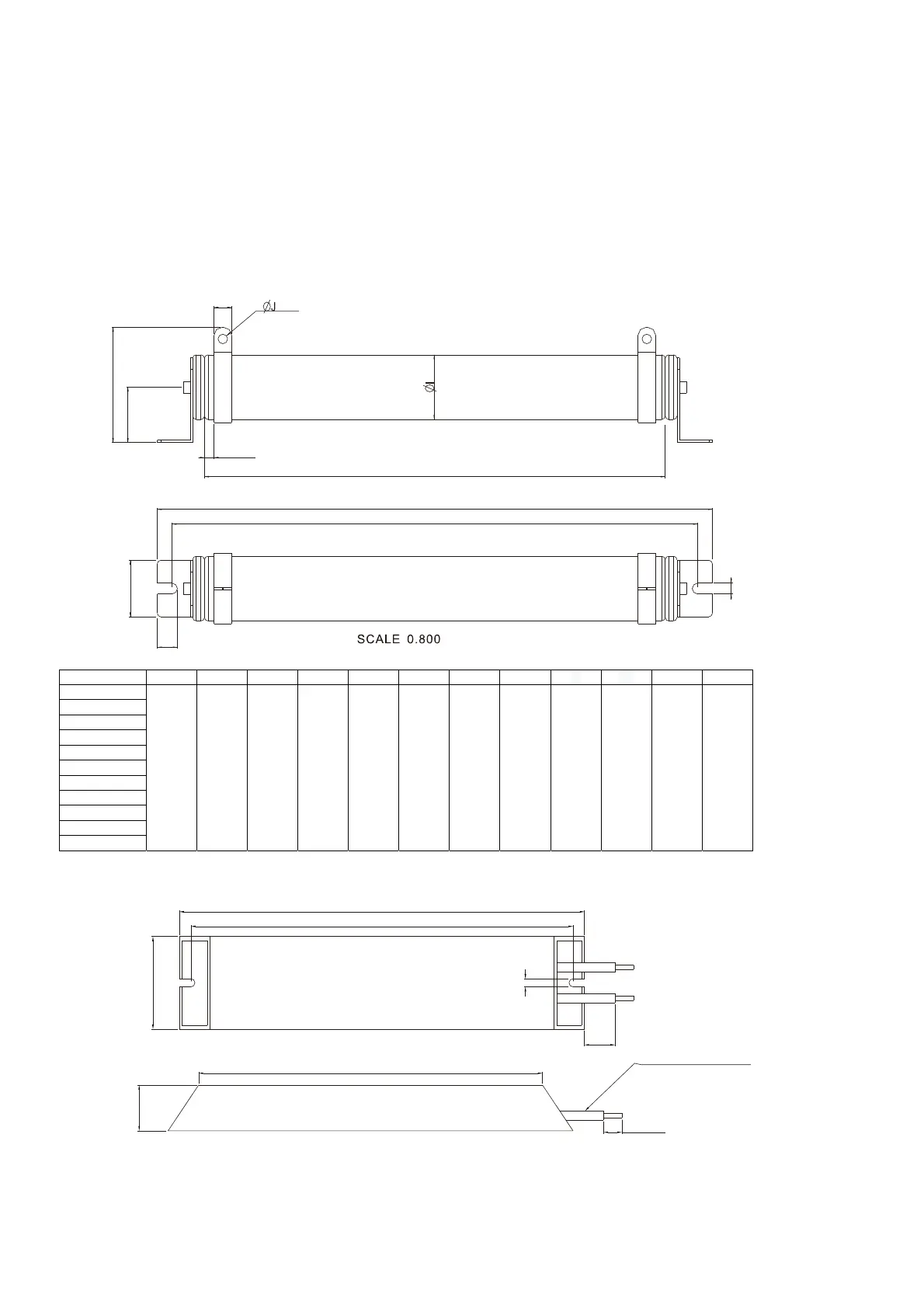

1.1 Wire wound resistors: For 1000 W and above, refer to the following appearance of wire wound resistor

(Figure7-1) and its model and specification comparison table (Table 7-5) for details.

A

B

C

D

H

F

K

G

E

L

Figure 7-1

Models and Specifications Comparison Table of Wire Wound Resistors:

Unit: mm

Models A B C D E F G H

Ø ØJ K L

BR1K0W4P3

470±10 445±5 48±0.2 9.1±0.1 390±3 98±5 47±5 15±1 55±5 8.1±0.1 21±0.2 8±1

BR1K0W5P1

BR1K0W016

BR1K0W020

BR1K0W075

BR1K2W3P9

BR1K2W015

BR1K5W3P3

BR1K5W012

BR1K5W013

BR1K5W043

Table 7-5

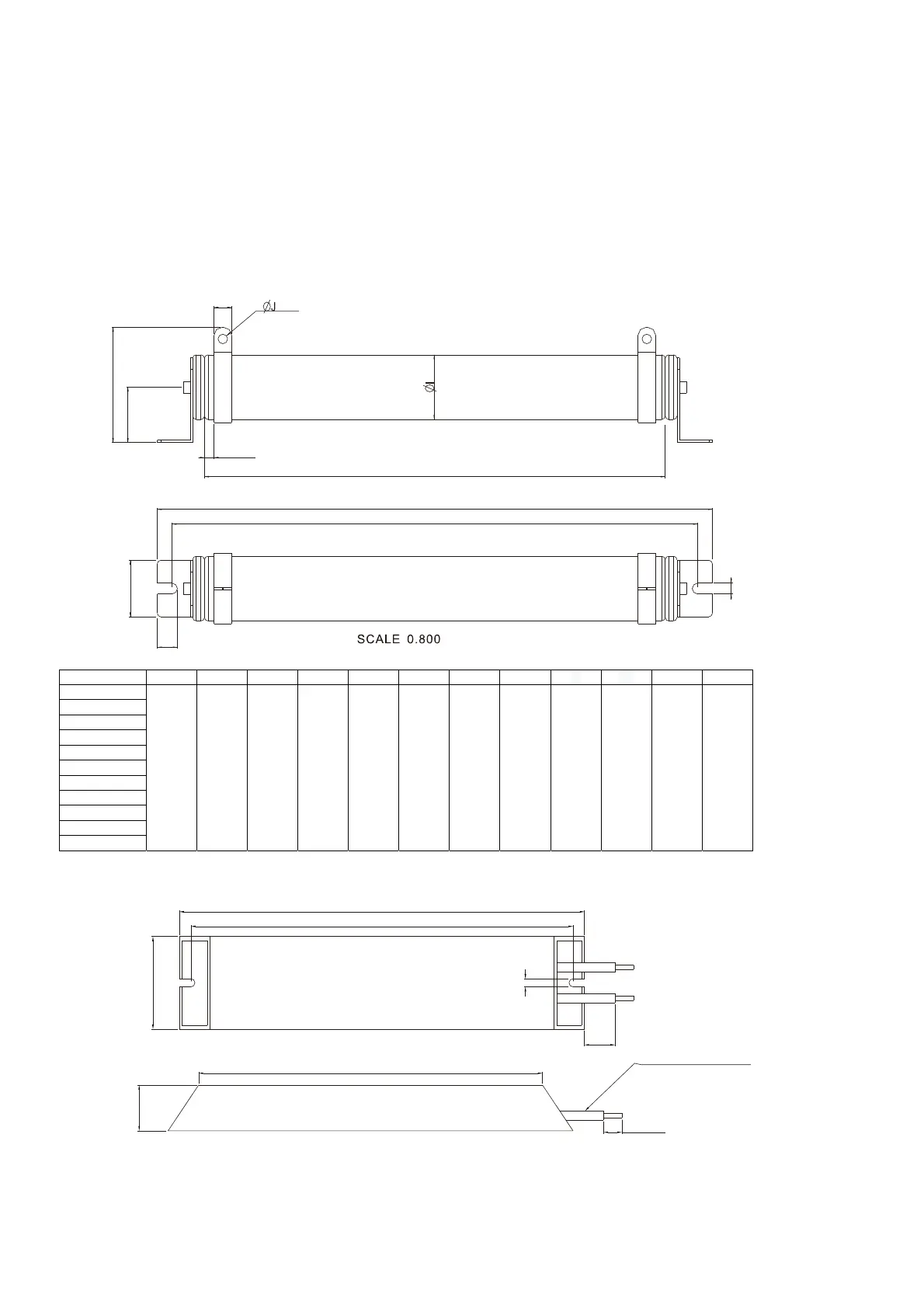

1.2 Aluminum housed resistors: For below 1000 W, refer to the following appearance of aluminum-housed

resistor (Figure 7-2) and its model and specification comparison table (Table 7-6) for details

A

W

L1

L 2

L

H

L3

12.0

16A WG, 1. 31 8 M M2

Figure 7-2

Loading...

Loading...