Chapter 12 Descriptions of Parameter SettingsC2000 Plus

12.1-08-5

Pr.00-04 = 10 (Display PID feedback (b) (%)).

Pr.01-12 Acceleration Time is set according to actual conditions.

Pr.01-13 Deceleration Time is set according to actual conditions.

Pr.00-21 = 0, operate through the digital keypad.

Pr.00-20 = 0, the digital keypad controls the set point.

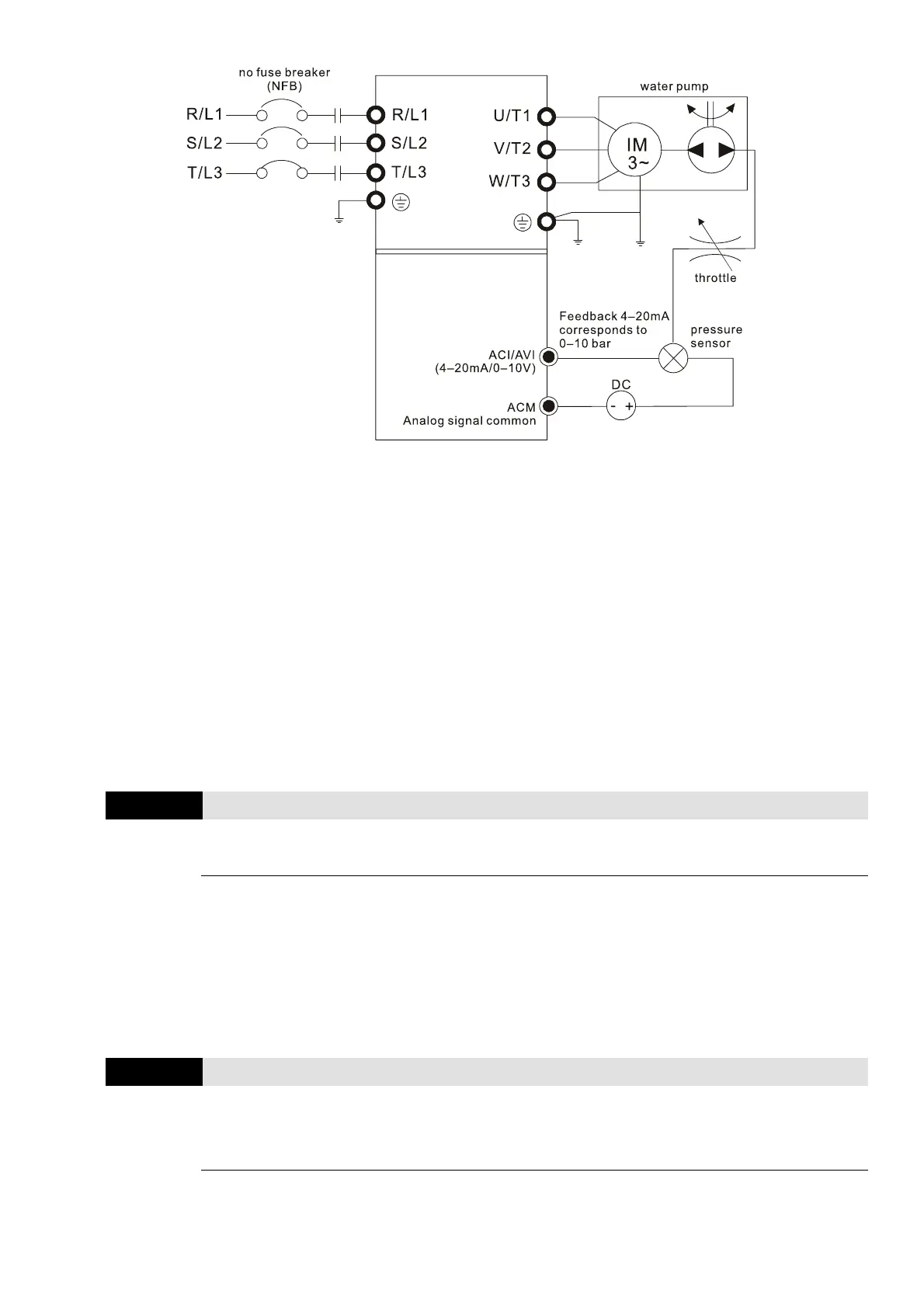

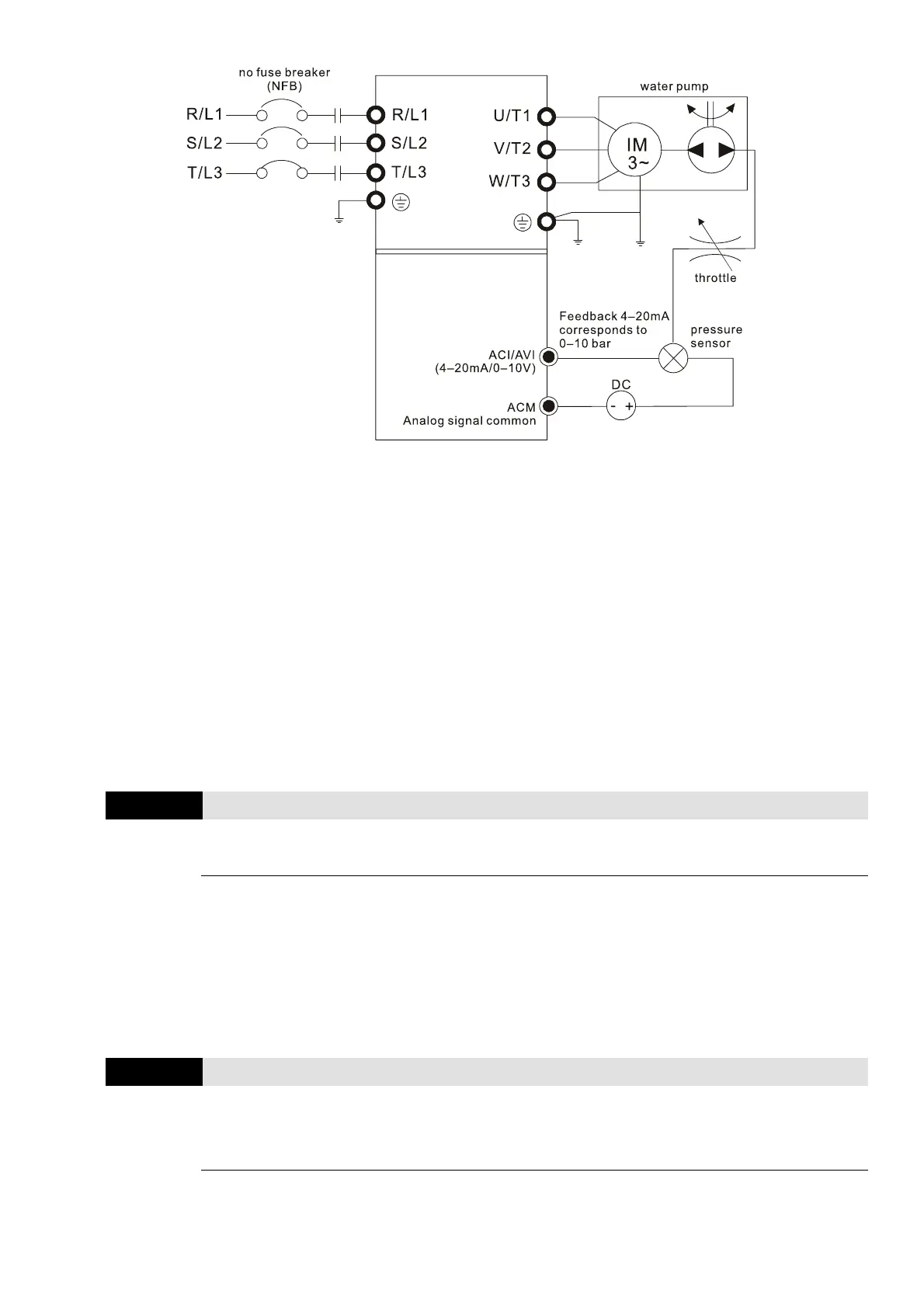

Pr.08-00 = 1 (Negative PID feedback from analog input)

ACI analog input Pr.03-01 = 5, PID feedback signal.

Pr.08-01–08-03 is set according to actual conditions:

If there is no oscillation in the system, increase Pr.08-01 (Proportional Gain (P))

If there is no oscillation in the system, decrease Pr.08-02 (Integral Time (I))

If there is no oscillation in the system, increase Pr.08-03 (Differential Time (D))

Refer to Pr.08-00 to Pr.08-21 for PID parameter settings.

08-01

Proportional Gain (P)

Default: 1.0

Settings 0.0–500.0

1.0: Kp gain is 100%; if the setting is 0.5, Kp gain is 50%.

Set the proportional gain to determine the deviation response speed. The higher the proportional

gain, the faster the response speed. Eliminates the system deviation; usually used to decrease

the deviation and get faster response speed, it also reduces the steady-state error. If you set the

value too high, overshoot occurs and it may cause system oscillation and instability.

If you set the other two gains (I and D) to zero, proportional control is the only effective parameter.

08-02

Integral Time (I)

Default: 1.00

Settings 0.00–100.00 sec.

0.0: No integral

Use the integral controller to eliminate the deviation during stable system operation. The integral

control does not stop working until the deviation is zero. The integral is affected by the integral

Loading...

Loading...