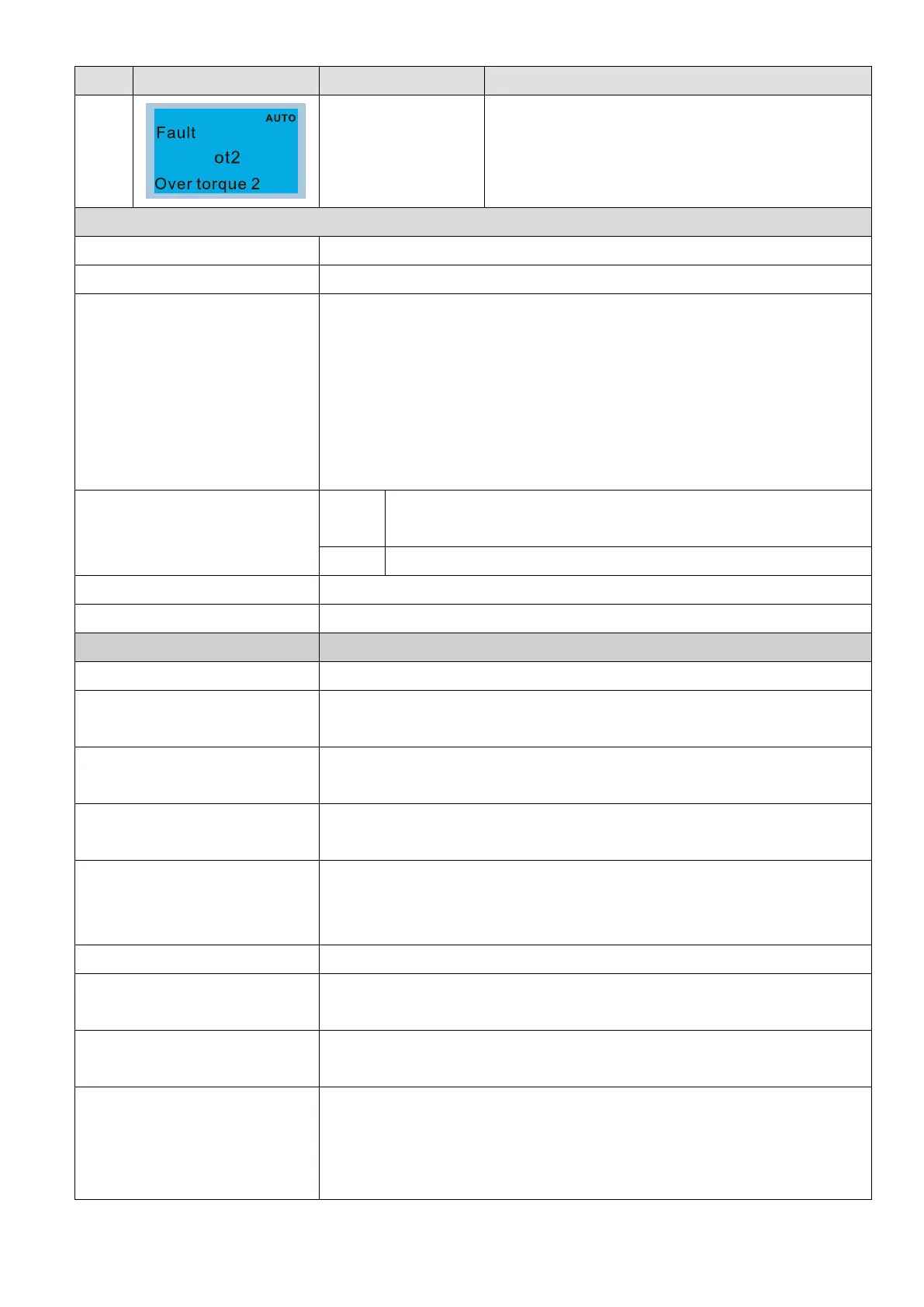

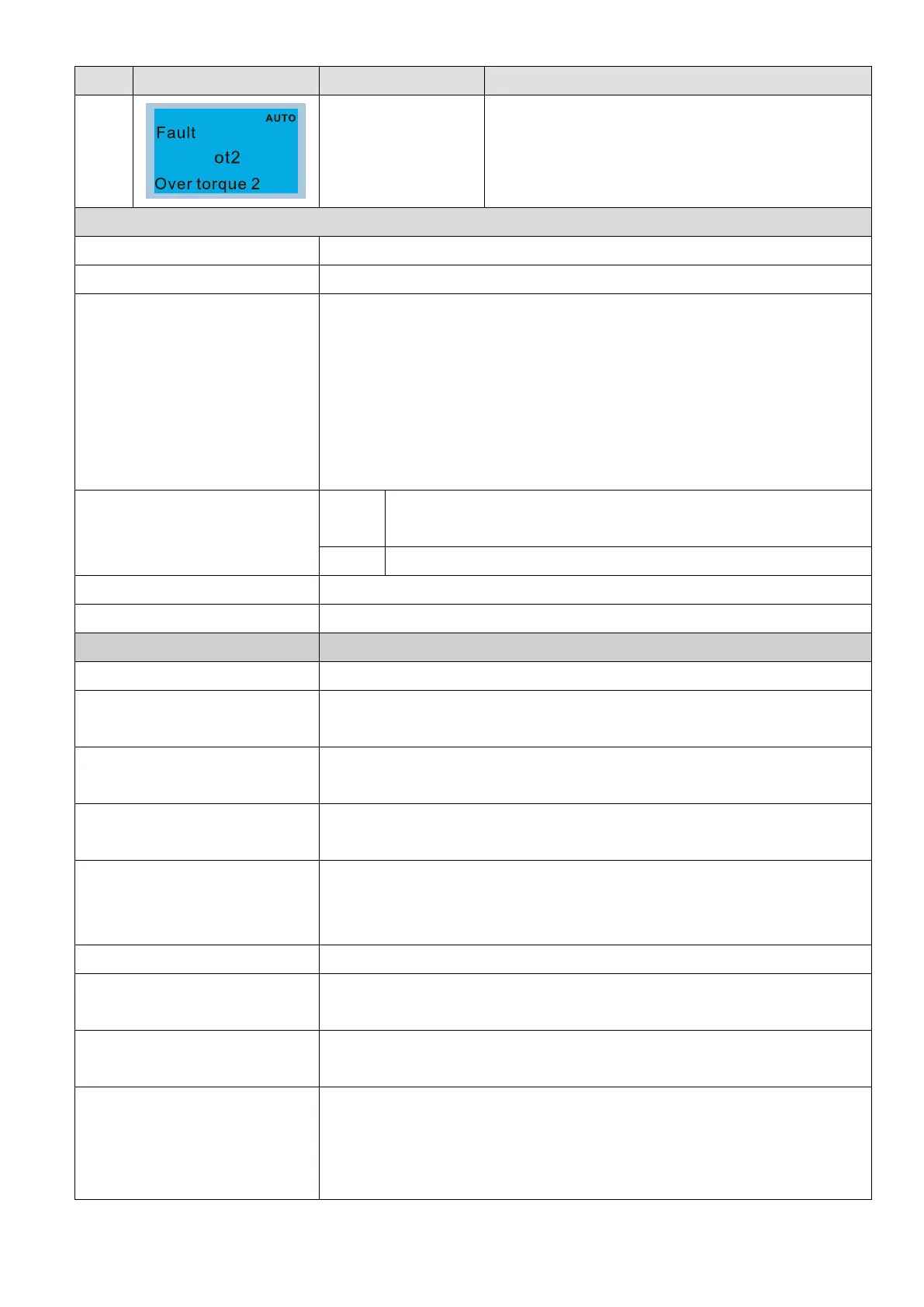

Chapter 14 Fault Codes and DescriptionsC2000 Plus

ID* Display on LCD Keypad Fault Name Fault Descriptions

27

Over torque 2

(ot2)

When output current exceeds the over-

level (Pr.06-10) and exceeds over-

(Pr.06-11), and when Pr.06-09 is set to 2 or 4,

fault displays.

Action and Reset

Action condition Pr.06-10

Action time Pr.06-11

Fault treatment parameter

Pr.06-09

0: No function

1: Continue operation after Over-torque detection during constant speed

operation

2: Stop after Over-torque detection during constant speed operation

3: Continue operation after Over-torque detection during RUN

4: Stop after Over-torque detection during RUN

Reset method

Reset condition

Auto

When Pr.06-09 = 1 or 3, ot2 is a “Warning”.

The warning is automatically

cleared when the output current < (Pr.06-10 - 5%).

Manual When Pr.06-09 = 2 or 4, ot2 is a “Fault”. You must reset manually.

Record Reset immediately

Active level When Pr.06-09 = 2 or 4, ot2 is a “Fault”, and the fault is recorded.

Cause Corrective Actions

Incorrect parameter setting Reset Pr.06-07 and Pr.06-08

Mechanical failure (e.g. over-

torque, mechanical lock)

Remove the causes of malfunction.

The load is too large.

Reduce the load.

Replace the motor with a larger capacity model.

Accel./Decel. time and working

cycle are too short

Increase the setting values for Pr.01-12–01-19 (accel./decel. time).

V/F voltage is too high

Adjust the settings for Pr.01-01–01-08 (V/F curve), especially

for the mid-point voltage (if the mid-point voltage is set too low, the

decreases at low speed).

The motor capacity is too small Replace the motor with a larger capacity model.

Overload during low-speed

operation

Decrease low-speed operation time.

Increase the motor capacity.

Torque compensation is too large

Adjust the torque compensation (refer to Pr.07-

26 torque compensation gain)

until the current reduces and the motor does no stall.

Improper parameter settings for

speed tracking function (including

restart at momentary power loss

and restart after fault)

Correct the parameter settings for speed tracking.

1. Start the speed tracking function.

2. Adjust the maximum current for Pr.07-09 speed tracking.

Loading...

Loading...