Chapter 12 Description of Parameter SettingsCP2000

12.1-07-3

Setting 1: Frequency tracking begins before momentary power loss and accelerates to the

master Frequency command after the drive output frequency and motor rotator speed are

synchronous. Use this setting when there is a lot of inertia with little resistance on the motor load.

For example, in equipment with a large inertia flywheel, there is NO need to wait until the

flywheel stops completely after a restart to execute the operation command; therefore, it saves

time.

Setting 2: Frequency tracking starts from the minimum output frequency and accelerates to the

master Frequency command after the drive output frequency and motor rotator speed are

synchronous. Use this setting when there is little inertia and large resistance.

This function is only valid when the RUN command is enabled.

Allowed Power Loss Duration

Default: 2.0

Settings 0.0–20.0 sec.

Determines the maximum time of allowable power loss. If the duration of a power loss exceeds

this parameter setting, the AC motor drive stops output.

Pr.07-06 is valid when the maximum allowable power loss time is ≤ 20 seconds and the AC

motor drive displays “Lv”. If the AC motor drive is powered off due to overload, even if the

maximum allowable power loss time is ≤ 20 seconds, the operation mode set in Pr.07-06 does

not execute.

Base Block Time

Default: Depending on the

model power

Settings 0.0–5.0 sec. (Depending on the model power)

When momentary power loss is detected, the AC motor drive blocks its output and then waits for

a specified period of time (determined by Pr.07-08, called Base Block Time) before resuming

operation. Set this parameter to the time that allows the residual regeneration voltage at the

output side to decrease to 0V before activating the drive again.

This parameter is not only for the B.B. time, but also is the re-start delay time after free run.

The RUN command during a free run operation is memorized, and runs or stops with the last

frequency command after the delay time.

This delay time is only applicable in “Re-start after coast to stop” status, and does not limit ramp

to stop. The coast to stop can be caused by various control command source, or by errors.

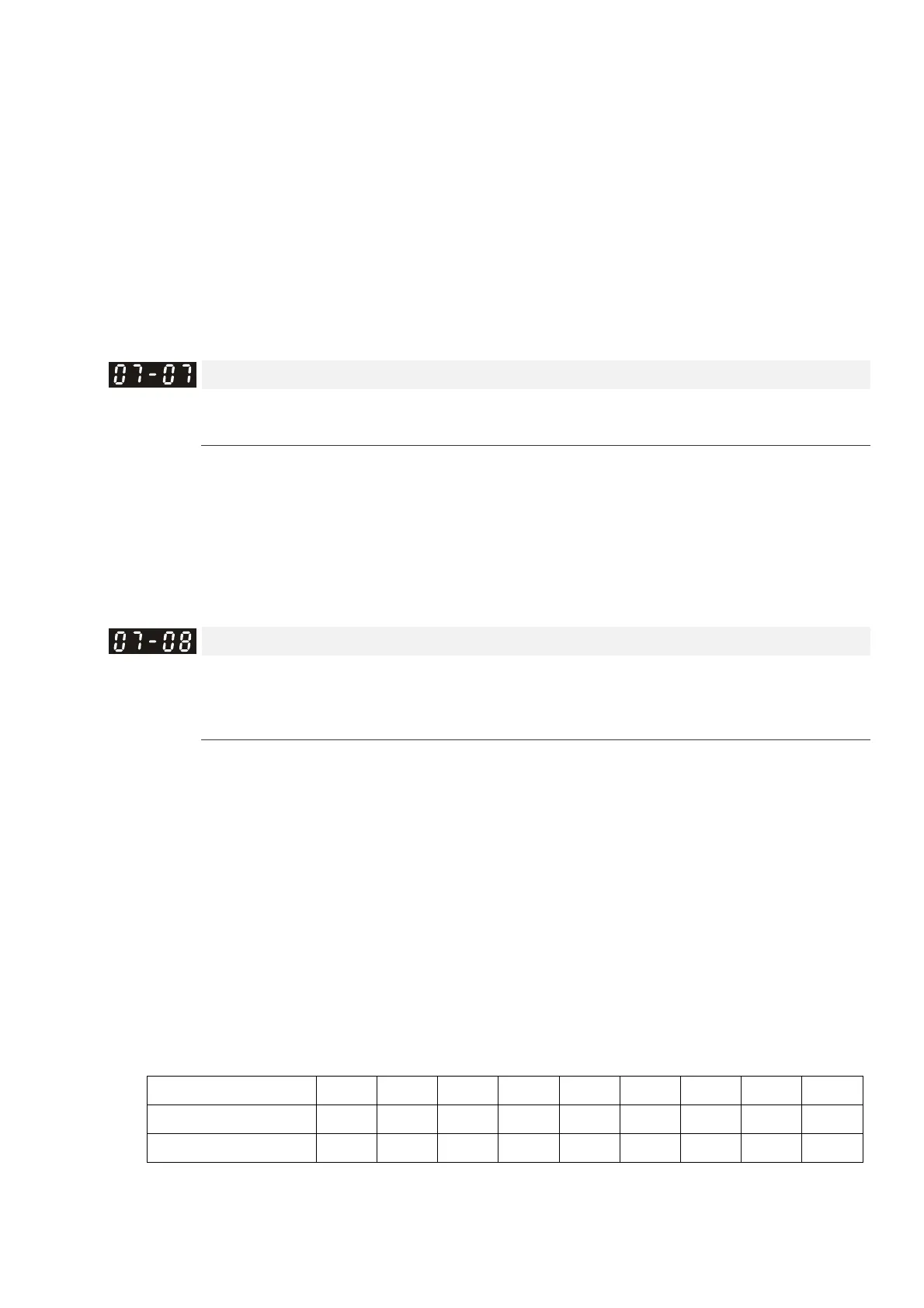

Following table is the recommended setting for re-start delay time of each model power. You

must set Pr. 07-08 according to this table (the default of each model power is based on this table

as well).

kW 007 015 022 037 040 055 075 110 150

HP 1 2 3 5 5.5 7.5 10 15 20

Delay time (sec.) 0.3 0.4 0.5 0.6 0.7 0.7 0.8 0.9 1

Loading...

Loading...