Chapter 12 Description of Parameter SettingsCP2000

12.1-12-18

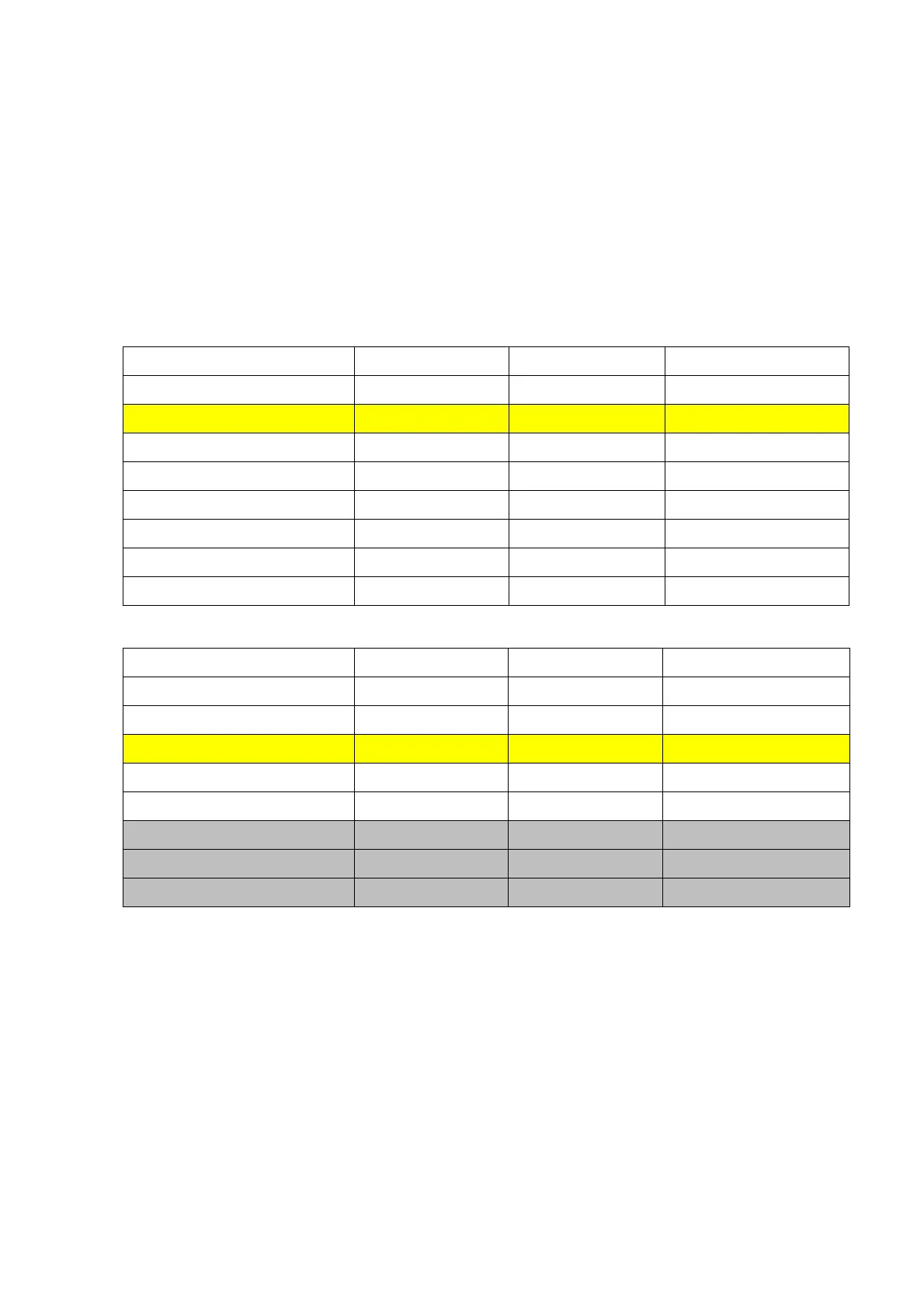

When the minimum operation time (Pr.12-27=1) is enabled, the drive sorts the operation hours

according to the amount of running motors at the moment, and then choose the motor that has

the minimum operation hour to start after RUN command.

As Example 1 below shows, the drive starts Motor 2, which having a minimum operation time

among all eight motors.

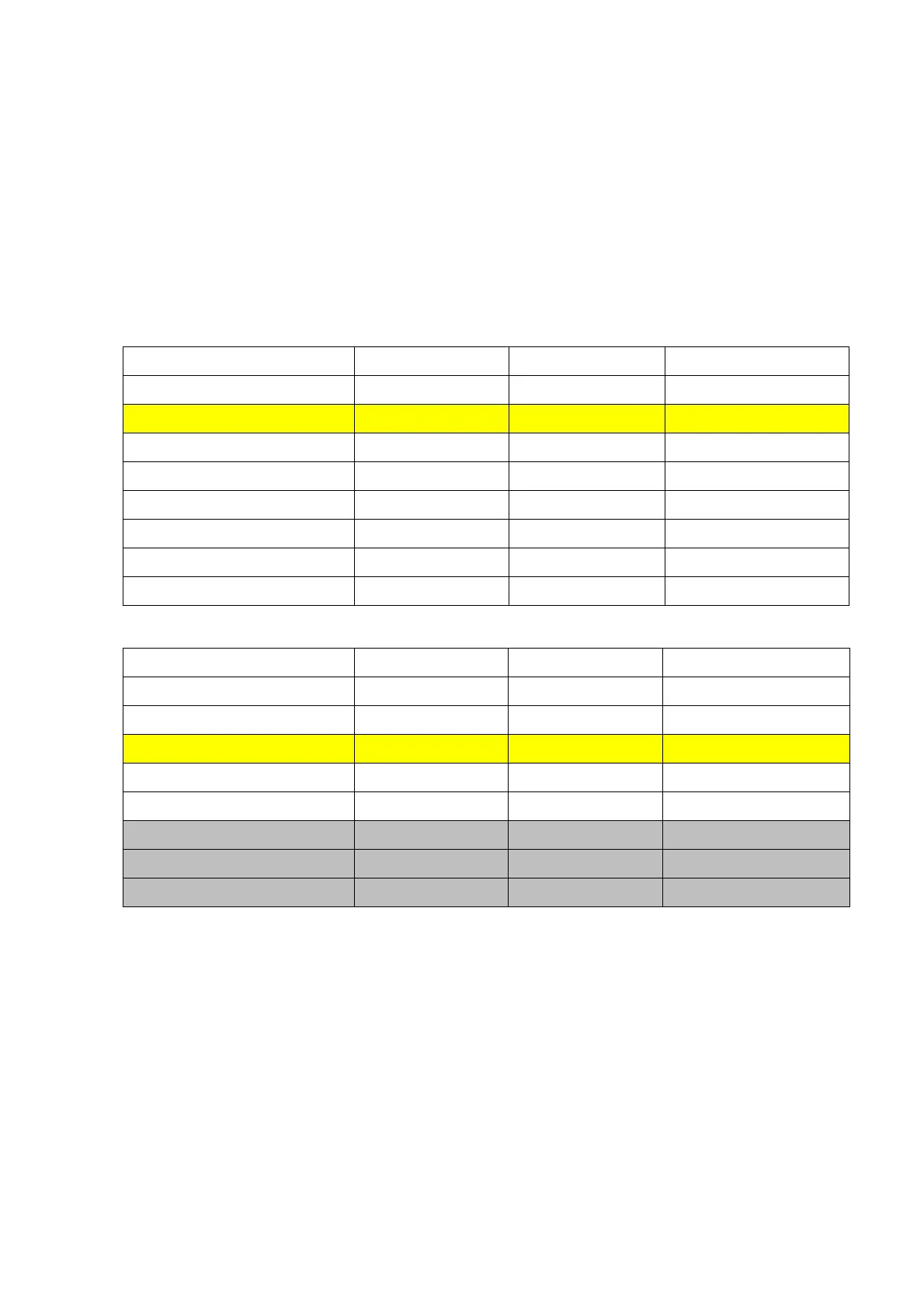

As Example 2 below shows, Motor 8 does not start though it has the minimum operation time,

because only Motor 1 to Motor 5 are started. Moreover, if more than one motors have the same

minimum operation hour, the number of the motor takes the priority. Therefore, Motor 3 starts

rather than Motor 5.

Motor operation time-Example 1

Motor No. / Motor Status Status Operating Hour Operating Min./ Sec.

Motor 1 ON 0 59 59

Motor 2 ON 0 12 12

Motor 3 ON 2 00 00

Motor 4 ON 0 43 11

Motor 5 ON 1 33 00

Motor 6 ON 3 50 05

Motor 7 ON 1 05 22

Motor 8 ON 10 20 21

Motor operation time-Example 2

Motor No. / Motor status Status Operating Hour Operating Min./ Sec.

Motor 1 ON 0 59 59

Motor 2 ON 5 12 12

Motor 3 ON 0 33 00

Motor 4 ON 0 43 11

Motor 5 ON 0 33 00

Motor 6 OFF 3 50 05

Motor 7 OFF 1 05 22

Motor 8 OFF 0 00 01

Loading...

Loading...