C244, 320207, REV B LCC_LCD1-16/51 Oven Owner’s Manual

©2021 ITW EAE. All rights reserved. Despatch is a registered trademark in the U.S. and other

countries. No part of the contents of this manual may be reproduced, copied or transmitted in any form

or by any means without the written permission from ITW EAE - Despatch, unless for purchaser's

personal use.

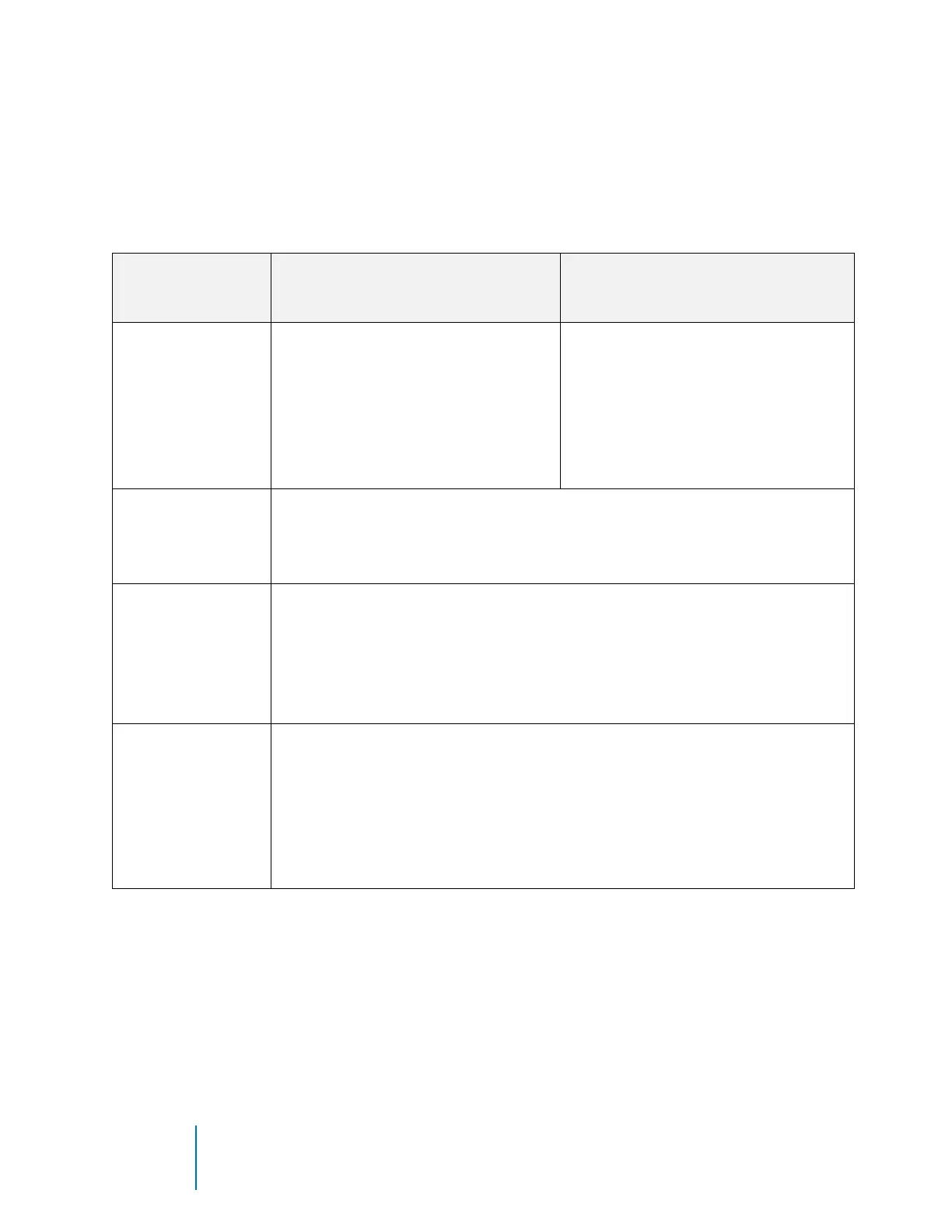

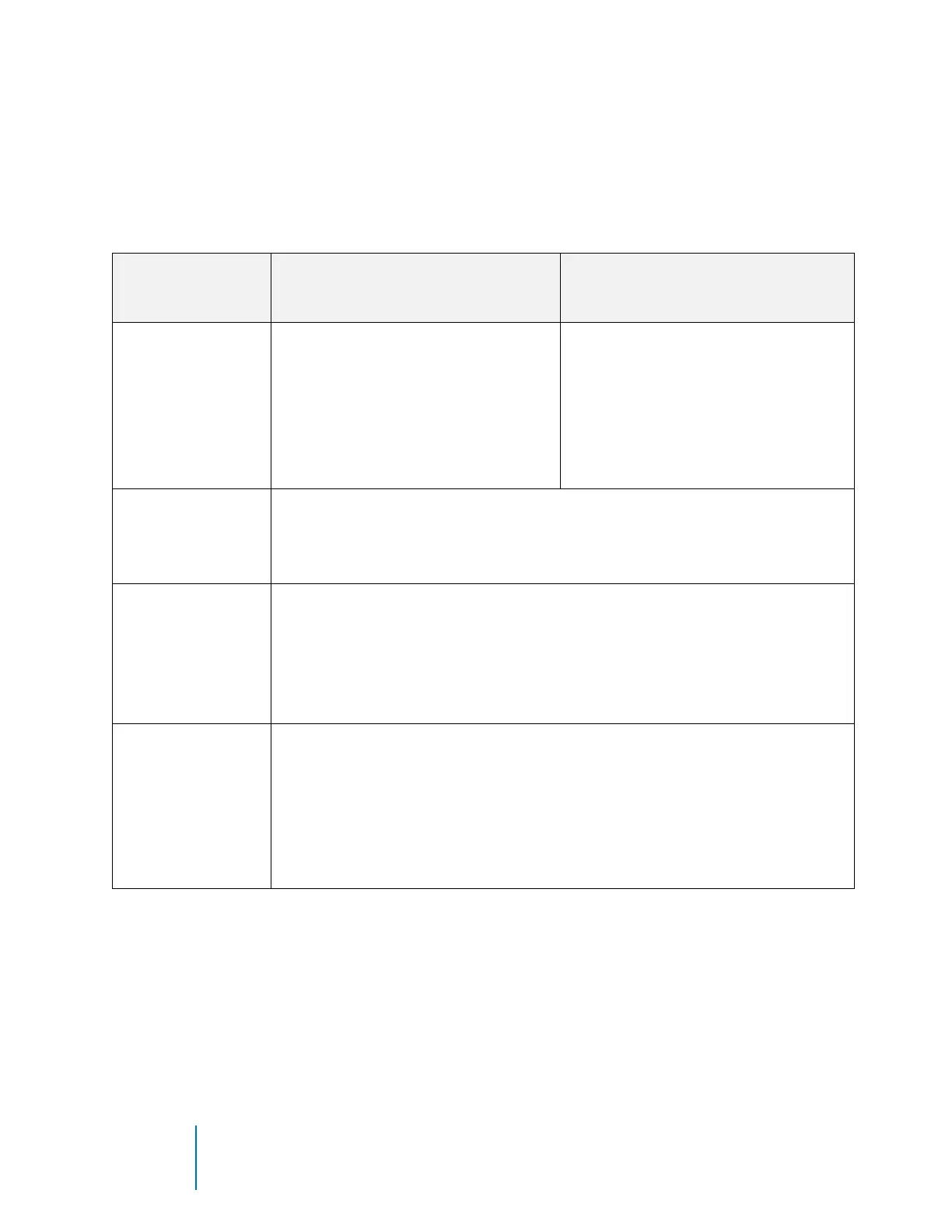

5.2.2. Oven Utility Connections

Utility connections vary slightly on different LCC/LCD models. Table 5 lists the

connection purposes and parameters. Refer to Figure 11 for a visual reference.

Table 5. Oven Utility Connections.

LCC/LCD Air Atmosphere models

with optional Water-cooled Model

LCC/LCD Nitrogen Atmosphere

models with standard water-

cooling

NITROGEN/CLEAN

DRY AIR INLET

• Clean Dry Air Inlet (70-80 psi

(4.83-5.52 bar))

• Used to purge water from coil

prior to heating oven

• 1/4” NPT female brass

connections provided

• Nitrogen Inlet (58-86 psi (4 -6

bar))

• Purge nitrogen, clean dry air

and water from coil prior to

heating the oven

• 1/4” NPT female brass

connections provided

• During cooling cycle, water flows through the water coil and out this

connection

• 3/8” NPT female brass connections provided

• Piping must be rated for up to 250°F (121°C)

• At the end of a cooling cycle, Nitrogen or Clean Dry Air is purged

through the water coil. Water and pressurized nitrogen/air exit this

connection for 30 seconds. Must be connected to gravity style drain

(no backpressure).

• 3/8” NPT female brass connections provided

• Piping must be rated for up to 250F (121C)

• Water Inlet for cooling

• 3/8” NPT female brass connections provided

• Requires 2 GPM flow at 16°C (55°F) to meet published cooling rates

• Maximum Pressure 100 PSI (6.89 Bar)

• Maintain a 20 PSI (1.4 bar) pressure differential at 2 GPM (7.6 lpm)

water flow

Loading...

Loading...