Model TP-700

TP-700 Instruction Manual Rev. 4.1 Page 6 of 42

When possible mount in an area void of high wind, accumulating dust, rain or splashing from hose spray, direct

steam releases, and continuous vibration. If the sensor cannot be mounted away from these conditions then

make sure the Detcon Harsh Environment Splashguard accessory is used.

Do not mount in locations where temperatures will exceed the operating temperature limits of the sensor. Where

direct sunlight leads to exceeding the high temperature-operating limit, use a sunshade to help reduce

temperature.

2.3 Sensor Contaminants and Interference

Solid State H

2

S sensors may be adversely affected by exposure to certain airborne substances. Loss of sensitivity

or corrosion may be gradual if such materials are present in sufficient concentrations.

The more common materials that potentially cause problems with the sensors are as follows:

• Silicone vapors such as those found in greases and lubricants

• Halide Compounds containing Chlorine, Chlorine Dioxide, Fluorine, HF, HCl, and Bromine

• Caustic and Acid liquids and concentrated vapors

• Heavy metals such as tetraethyl lead

The presence of such contaminants in an area does not preclude the use of this H

2

S sensor technology, although

it is likely that the sensor lifetime will be shorter as a result. Use of this sensor in these environments may

require more frequent calibration checks to ensure safe system performance.

Solid State H

2

S sensors require O

2

in the background gas and the reading is affected by changing O

2

levels.

Interference Data

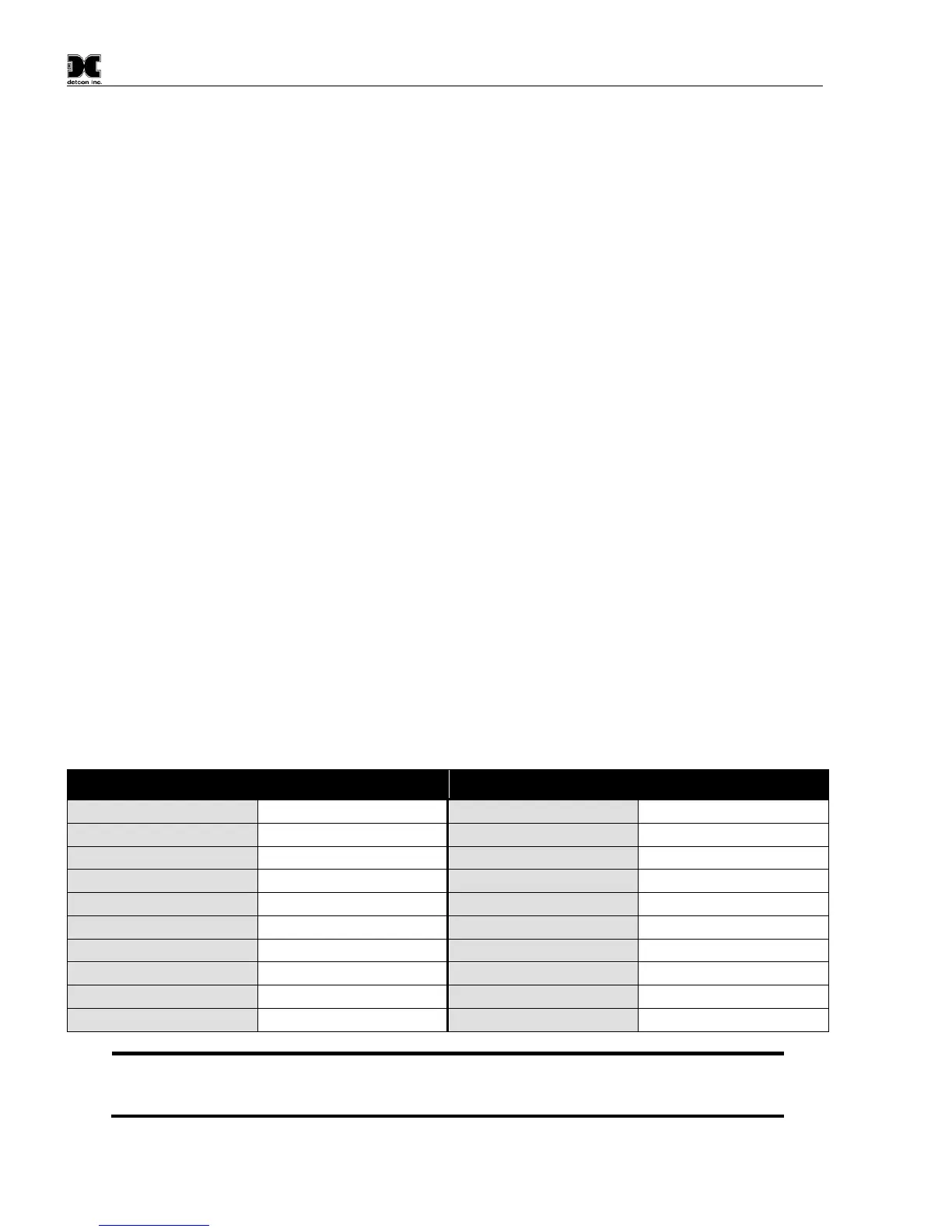

There are some gases typically found in industrial environments that can cause a cross-interference response on

the sensor. See the Table below for some examples.

Table 1 Cross Interference Gases

GAS PPM GAS PPM

NOTE: The Detcon MOS Sensor Cell can be damaged to the point of non-functioning if the

unit is left off power and in the presence normal air levels of moisture for periods exceeding 8

Loading...

Loading...