45

If the stem to guide clearance exceeds the service limit:

Determine if the new guide with standard dimensions would bring the clearance within tol-

erance, if so replace any guide as necessary and ream to fit. If the stem to guide clearance

exceeds the service limit with new guides, replace the valves also.

NOTE: Recondition the valve seats when valve guides are replaced.

VALVE GUIDE REPLACEMENT

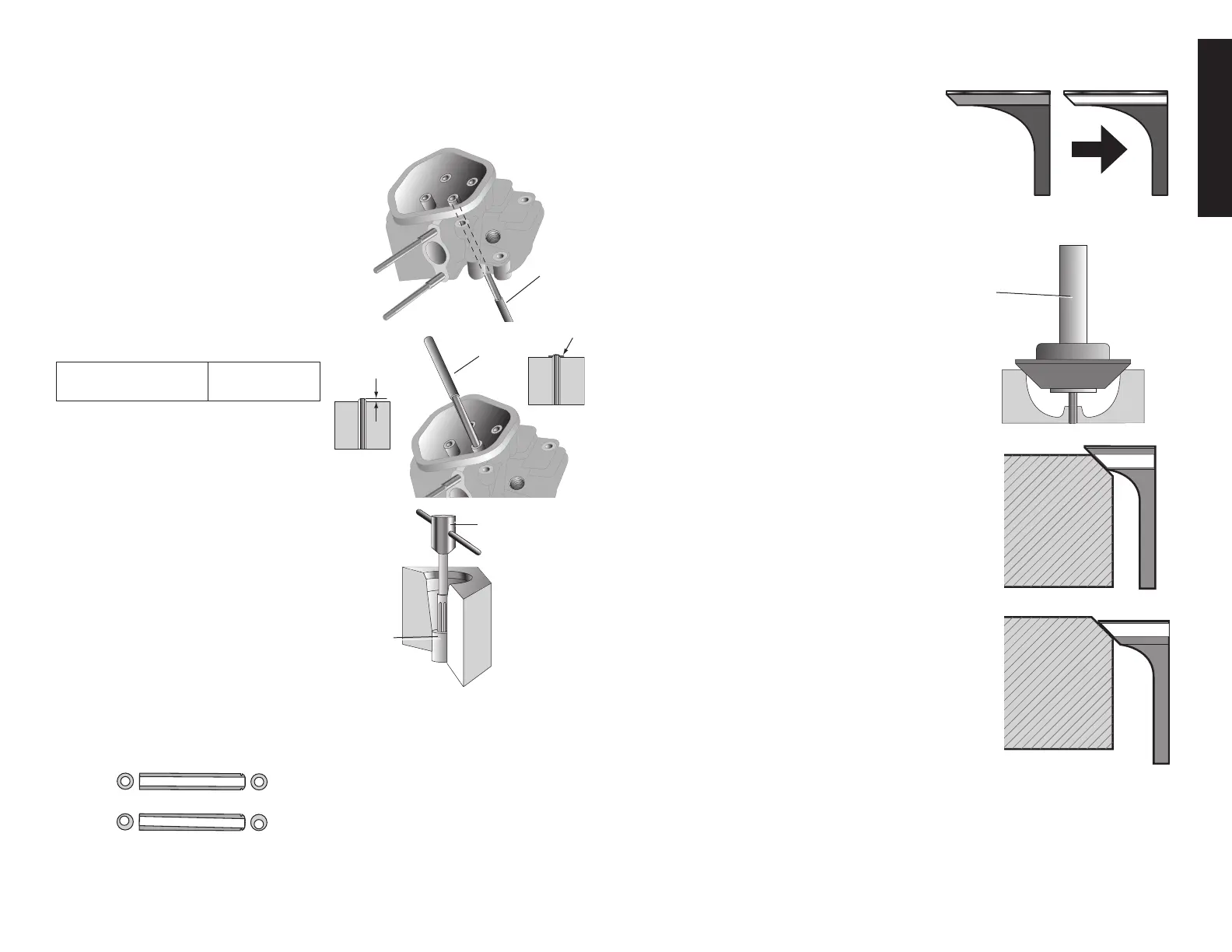

1. Drive the valve guides out of the head from

the combustion chamber side using a

valve guide driver.

2. Install the new valve guides from the

valve spring side of the cylinder head.

Exhaust side: Drive the exhaust valve

guide until the clip is fully seated as

shown.

Intake side: Drive the intake valve

guide to the specified height (measure

from the top of the valve guide to the

cylindercastingasshown)

IN valve guide

installation height

3.0mm(0.12")

3. After installation, inspect the valve guide

IN: 3.0 mm

.012 in

EX: CLIP

for damage, replace if necessary.

VALVE GUIDE REAMING

1. Coat the reamer and valve guide with

cutting oil.

2.Rotate the reamer clockwise through

the valve guide the full length of the

reamer.

3.Continuetorotatethereamerclockwise

while removing it from the valve guide.

4. Thoroughly clean the cylinder head

to remove any cutting oil residue and

chips.

5.Check thevalveguide bore: it should

be straight, round and centered in

the valve guide. Insert the valve and check operation. If the valvedoes not operate

smoothly, the guide may have been bent during installation. Replace the valve guide if

it is bent or damaged.

6.ChecktheValveGuidetoStemClearance.

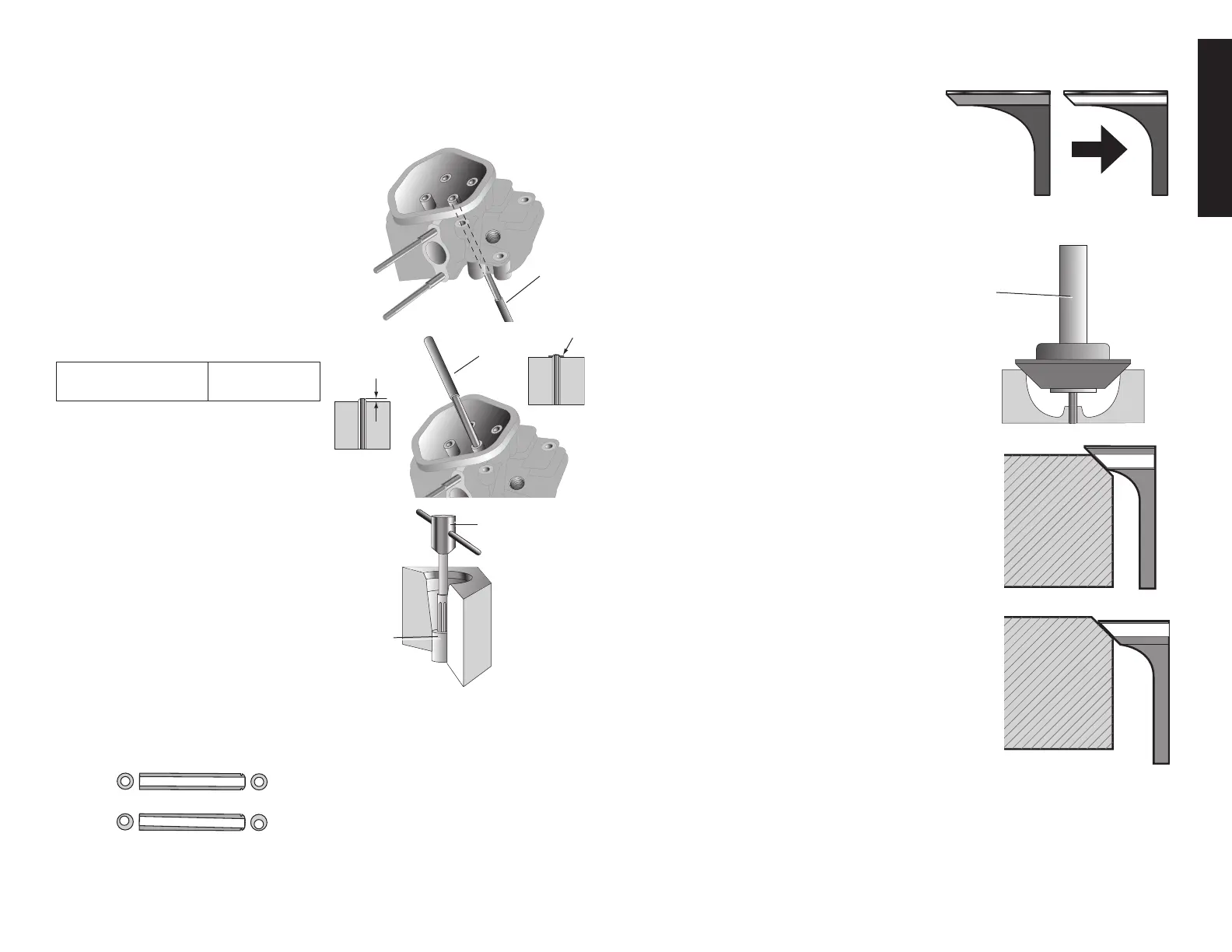

VALVE SEAT RECONDITIONING

1. Clean the combustion chamber and valve

seats(V8)toremovecarbondeposits.

2. Apply a light coat of Prussian Blue or eras-

ablefelt-tippedmarkeronvalveface.

3. Insert the valve and snap it closed against

the seat several times. Ensure the valve does

notrotateontheseat.Thetransferredmark-

ing compound will show any area of the seat

this is not concentric.

NOTE: Follow the valve seat cutter manufacture

instructions.

4. Use a 45° cutter to remove enough material

to produce a smooth and concentric seat.

Turn the cutter clockwise, never counterclockwise.

Continue to turn the cutter while lifting it from the valve

seat.

5. Use a 30° – 32° and 60° cutter to narrow and adjust the

valve seat so it contacts the middle of the valve face.

Use a 30° – 32° cutter to remove material from the

bottomedge(contacttoolow).

Use a 60° cutter to remove material from the top edge

(contact too high). Ensure the width of the finished

valve seat is within specifications.

V8

VALVE

SEAT

CUTTER

VALVE

GUIDE

DRIVER

REAMING TOOL

VALVE

GUIDE

CORRECT

INCORRECT

Loading...

Loading...