46

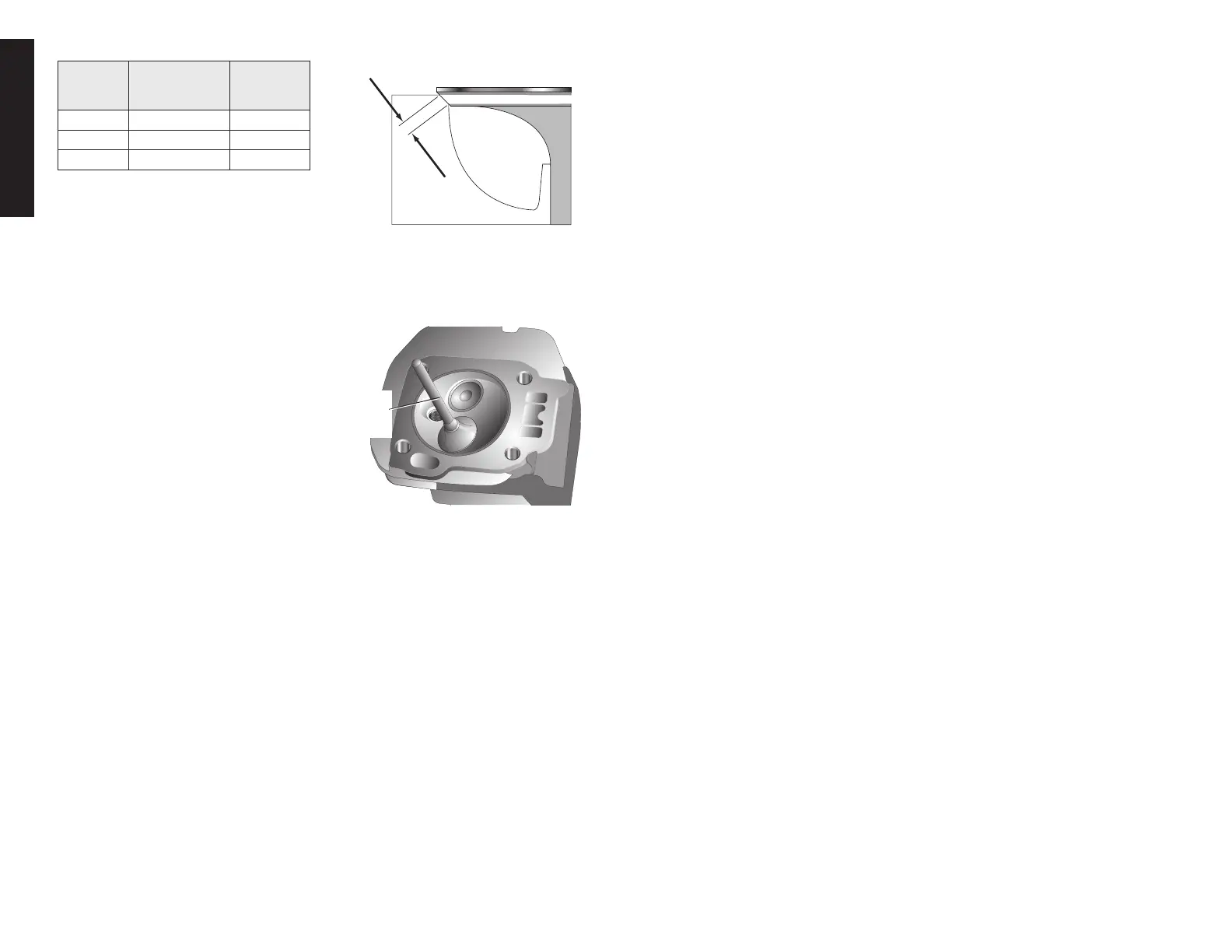

VALVE SEAT WIDTH

modeL

Standard

(mm)

Service

Limit

(mm)

dW168

0.7~0.9 2.0

dW177

0.7~0.9 2.0

dW188

0.7~0.9 2.0

6.Make a light pass with a 45° cutter to

remove any possible burrs at the edges of

the seat.

7. After resurfacing the seats, inspect for even

valveseating.ApplyalightcoatofPrussianBlueorerasablefelt-tippedmarkerontothe

valve face. Insert the valve and snap it closed against the seat several times. Ensure

the valve does not rotate on the seat.

Thetransferredmarkingcompoundshouldshowtheseatingsurfacehasgoodcontact

all the way around.

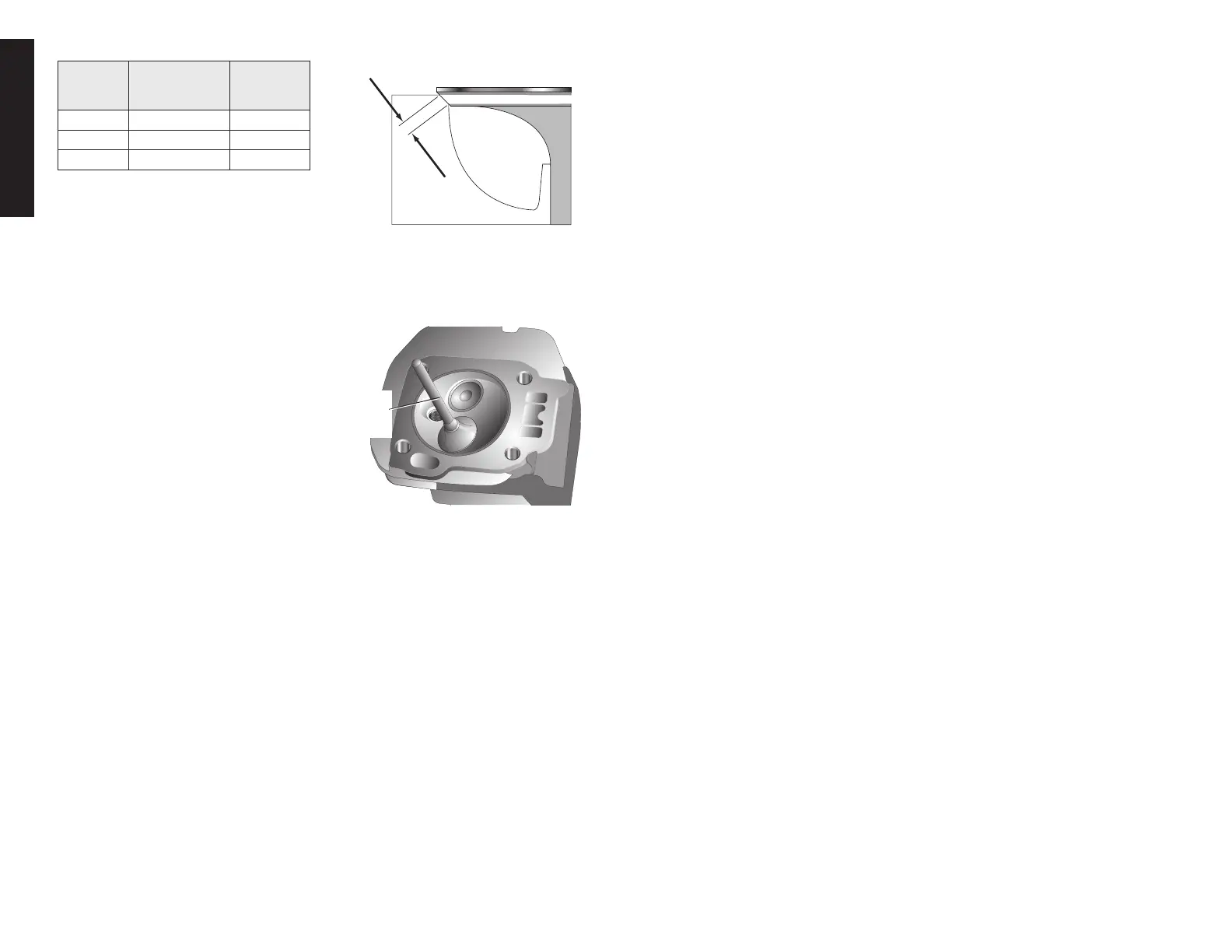

8. Lap the valves into their seats using a

hand valve lapper and lapping com-

pound(commerciallyavailable).

CAUTION: Risk of property damage.

Ensure all lapping compound is removed

from the engine before reassembly.

NOTE: Adjust the valve clearance after

reassembly.

VALVE

LAPPER

Loading...

Loading...