Dry-running compressor | TM 5.0 B

www.dilo-gmbh.com | C 1610-10 | Page 15 / 18

Maintenance:

All bearings are closed and provided with permanent lubrication.

The sliding surfaces of the cylinders are dry-running.

Do not lubricate the compressor with oil or grease.

Only the O-rings are slightly greased with a special grease before installation.

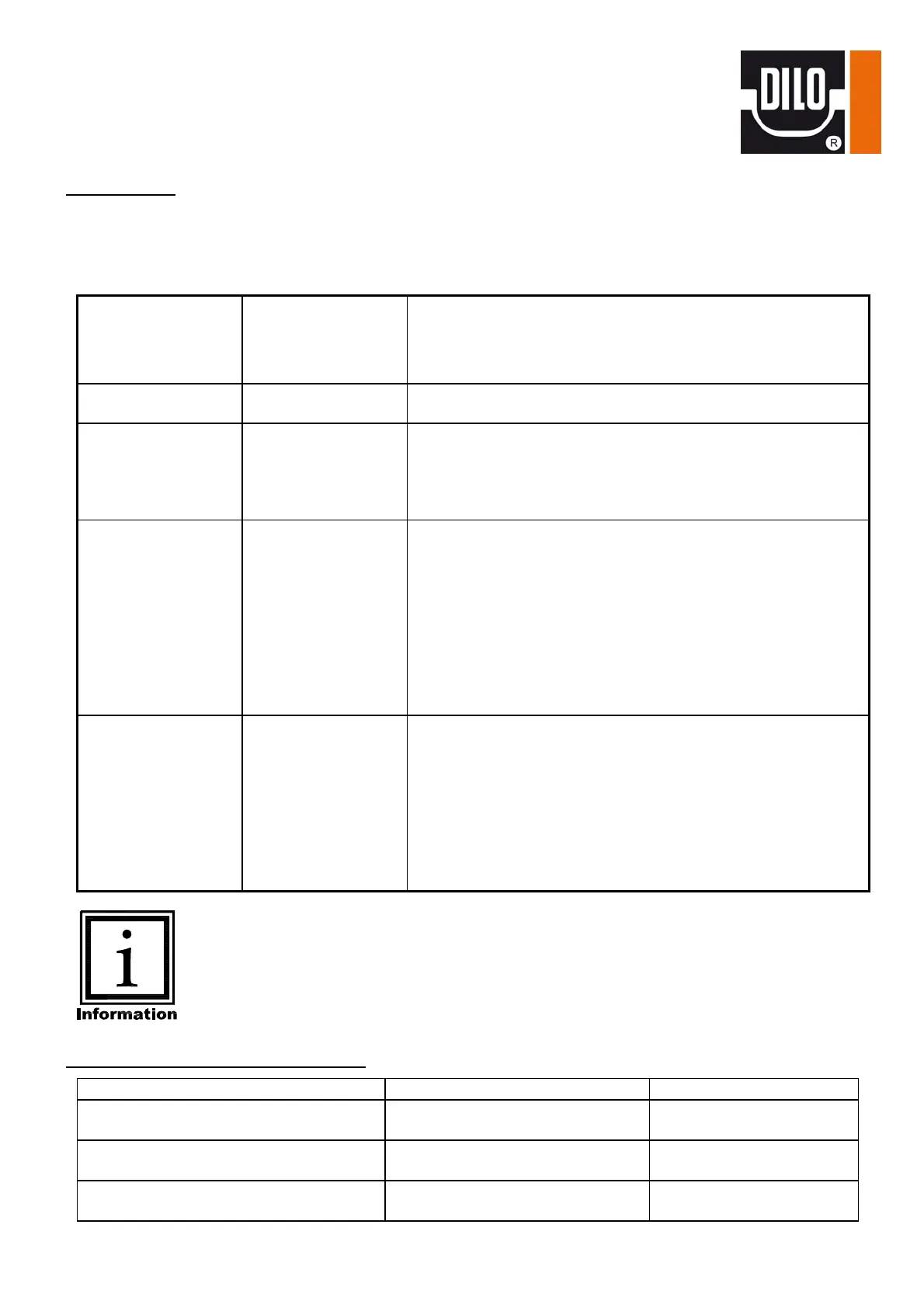

Maintenance

interval

Operating hours

Object Work

Weekly Noises Check

Every 500 hours

or year

Piston and guide

rings

Valve seats

Carry out pressure test with SF

6

(see page 16)

after 1500 h,

4000 h, 6500 h,

9000 h, ……..

Piston and guide

rings

Valve seats

Check, measure, exchange if necessary

(see page 16 to 18)

(1 piece spare part kit - piston ring with O-ring kit,

article no.: 6-1010-R013)

Check, exchange if necessary (see page 16 to 18)

(1 piece spare part kit – valve seats with O-ring kit,

article no.: 6-1010-R004)

every 2500 h Crank gear

Non return valve

Exchange

(1 piece replacement crankcase mounted completely,

article no.: 4-291-61)

Check, exchange, if necessary

(1 piece non return valve,

article no.: VR/A-02/8 P)

The specified maintenance intervals only apply for compressed SF

6

gas corresponding

to the quality stipulated in the IEC 60480 regulations. These maintenance intervals are

considerably shortened if the gas contains increased humidity values and / or

decomposition products.In this case the compressor must be rinsed after each

operation (also see the “Correct use” chapter).

Wearing parts are excluded from warranty!

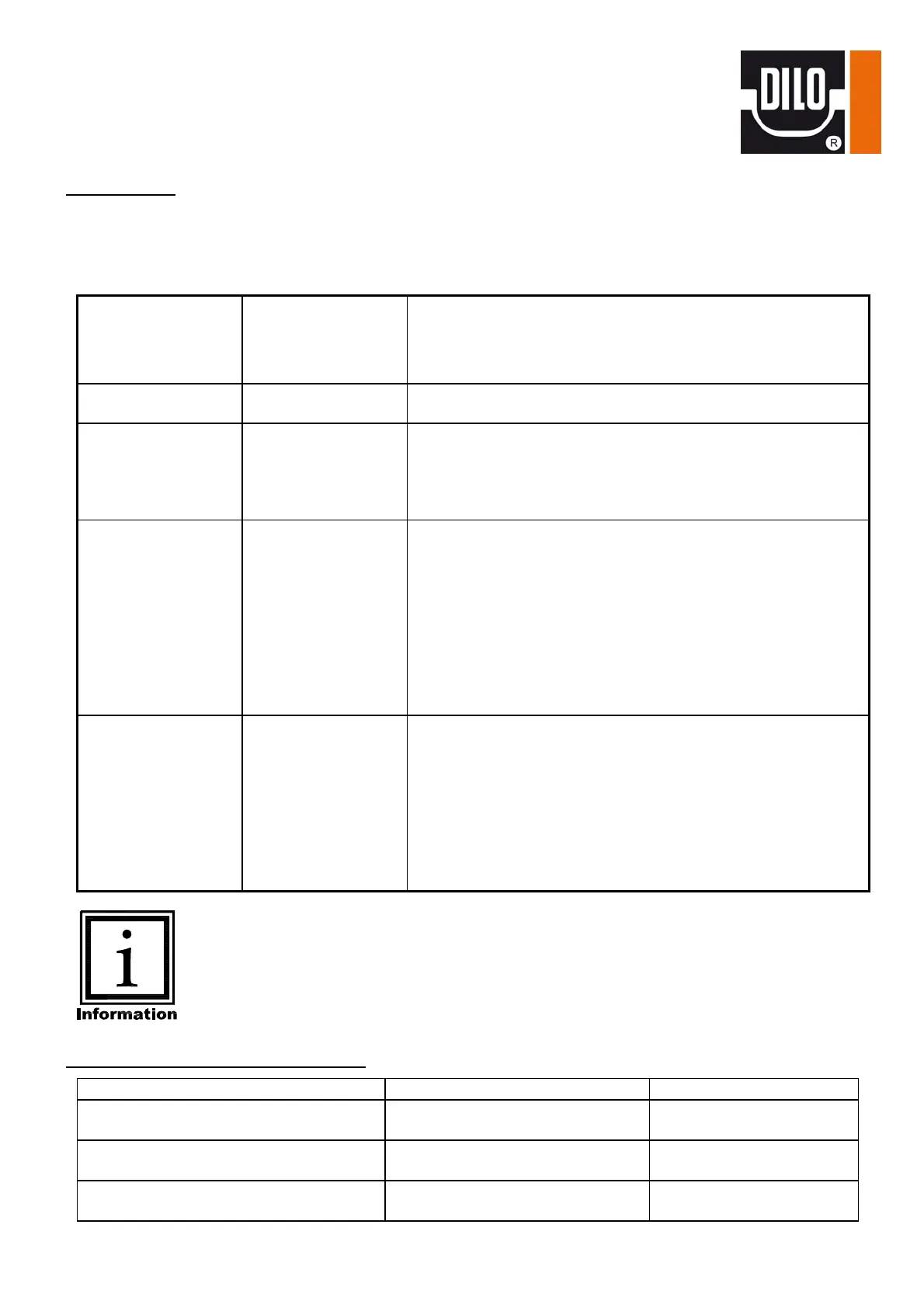

Examination in disassembled condition:

Radial minimum thickness

Dimension of new ring

Piston ring, Ø 54 mm

(Article no.: 05-1054-R012)

3.0 mm

4.0 mm

Guide ring, Ø 54 mm

(Article no.: 05-1054-R013)

3.1 mm

3.5 mm

High pressure piston ring, Ø 23 mm

(Article no.: 05-1054-R015)

4.0 mm

5.0 mm

Loading...

Loading...