Dry-running compressor | TM 5.0 B

www.dilo-gmbh.com | C 1610-10 | Page 16 / 18

Functional test (pressure test with SF

6

)

Connect the gauge, then the check valve (ball valve or solenoid valve) to the compressor output (in case

they are not already present downstream from the compressor in the service cart. If the compressor is

installed in the service cart the exact procedure is described in the operating manuals, chapter 9

“Maintenance and functional test of the compressor).

Close the check valve and start the compressor (suction pressure should be about p

e

0 bar) After a

certain time a pressure of p

e

48 bar should be obtained. Turn off the compressor!

If the compressor is turned off too late the compressed SF

6

is released in the atmosphere via the safety

valve p

e

55 bar (upstream from the compressor output).

In case a pressure of p

e

48 bar is not reached exchange the valve seats. After the exchange repeat the

pressure test.

If the pressure is still not reached the piston and guide rings are to be exchanged.

Verification and disassembly of the piston and guide rings and valve seats

Attention: Only carry out if the plant is depressurized and disconnected from the power

supply!

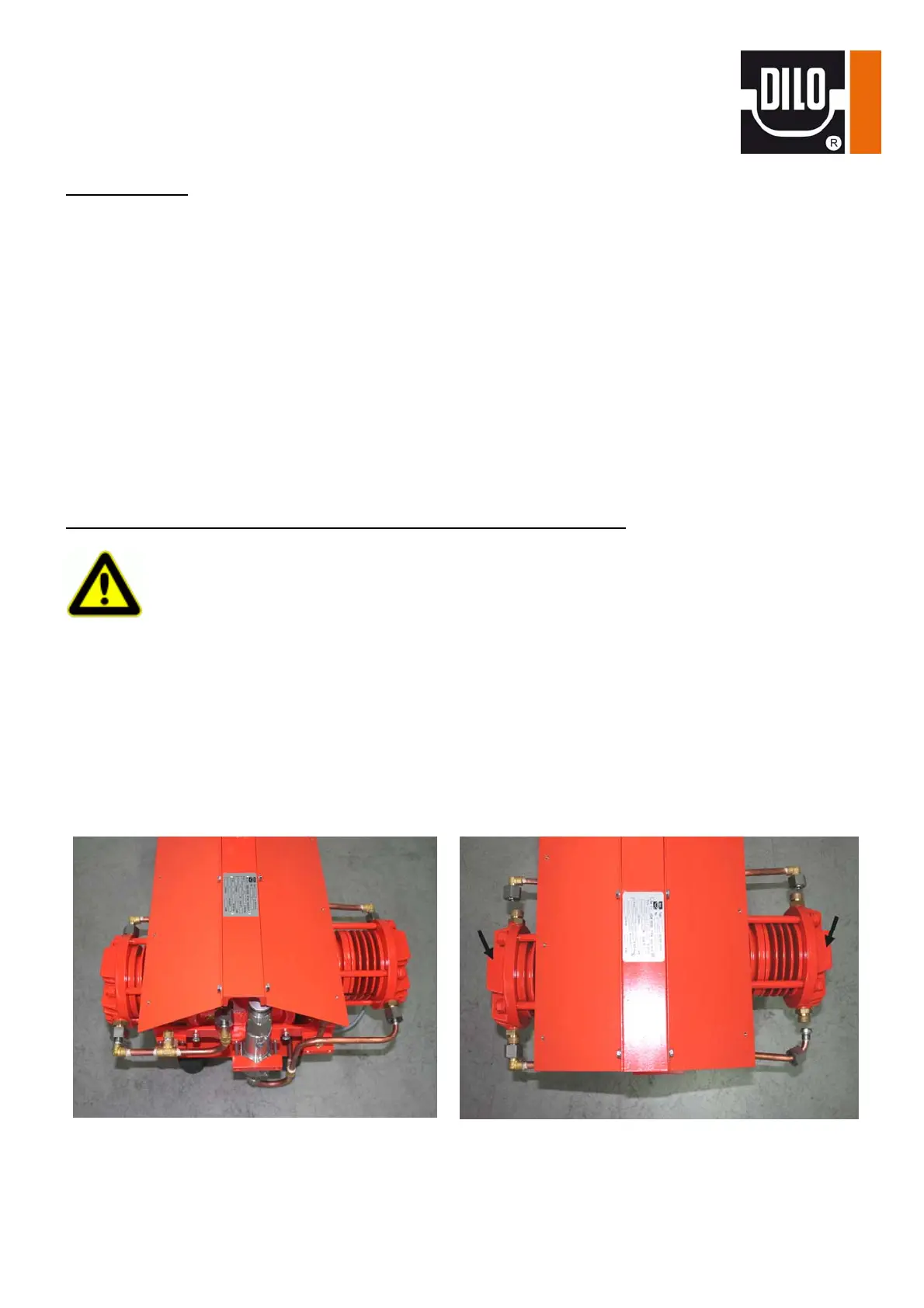

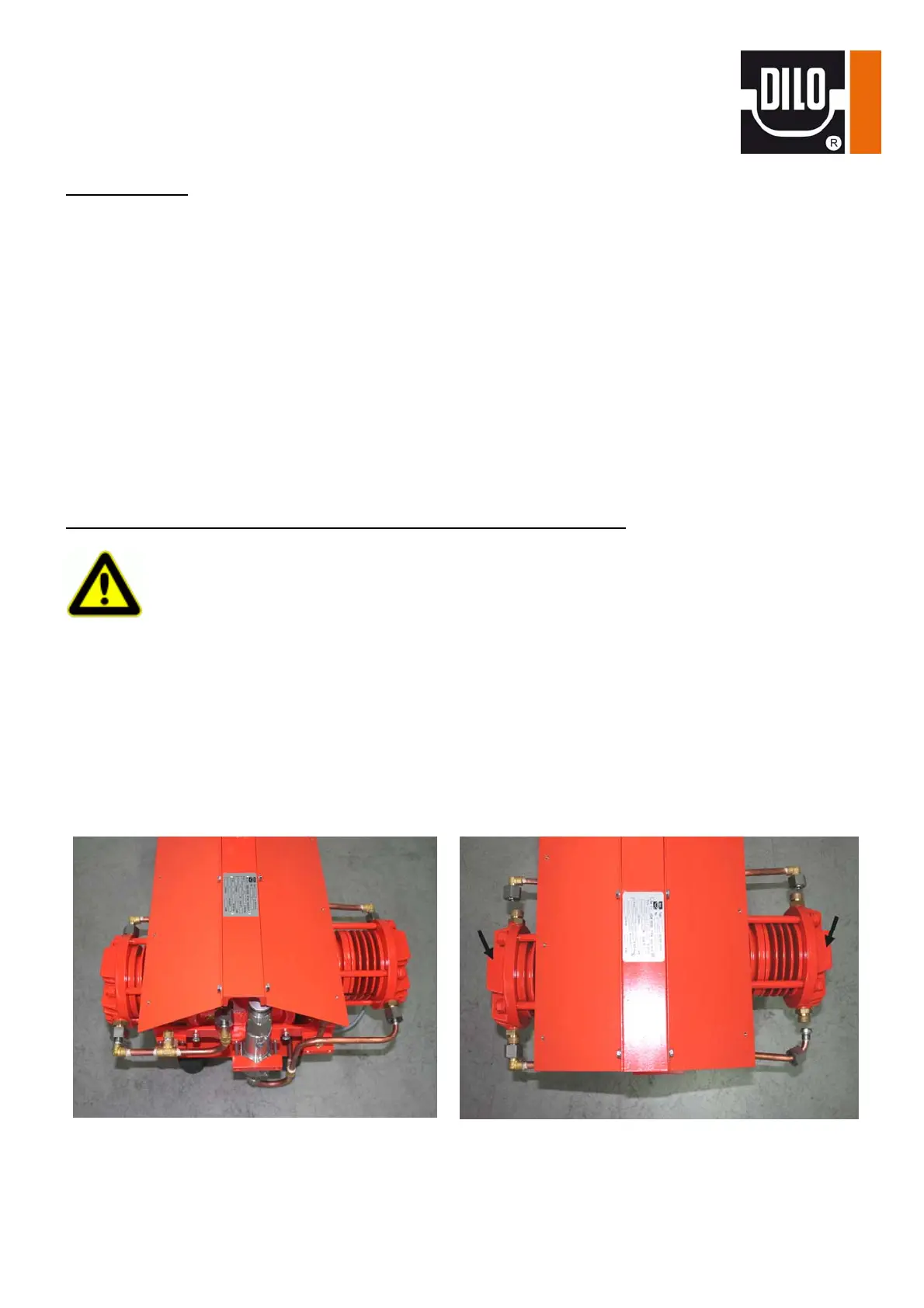

Disassemble the front cover (2 pieces).

Disassemble all tubings on the cylinder caps. Then dismount all cylinder caps.

Danger

Loading...

Loading...