Dry-running compressor | TM 5.0 B

www.dilo-gmbh.com | C 1610-10 | Page 18 / 18

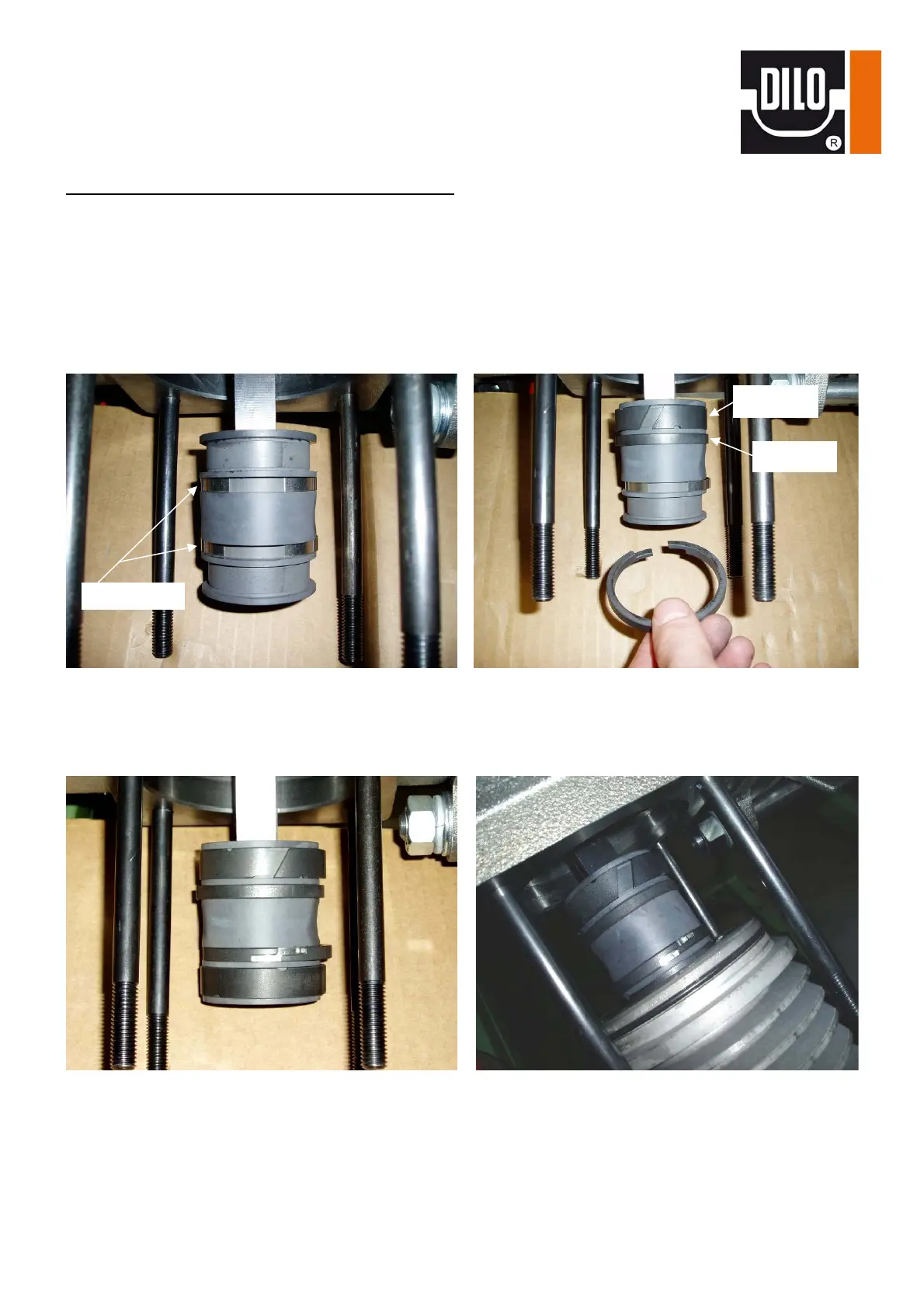

Assembly of piston and guide rings and valve seats

Prior to assembly, clean all O-rings and piston ring grooves.

Exchange all O-rings and slightly grease them with silicone grease.

Mount two tension springs per piston.

Bend the guide and piston rings as little as possible and slide on to the piston. Mount the piston

ring at about 180 degrees with respect to the tension spring (that means in case the open end of

the tension spring is at the top the open end of the piston ring must be at the bottom)

Turn the piston and guide ring so that the open ends are 180 degrees out of position to each

other (see photo down left).

Do not grease the slide surface of the pistons neither with oil nor with grease.

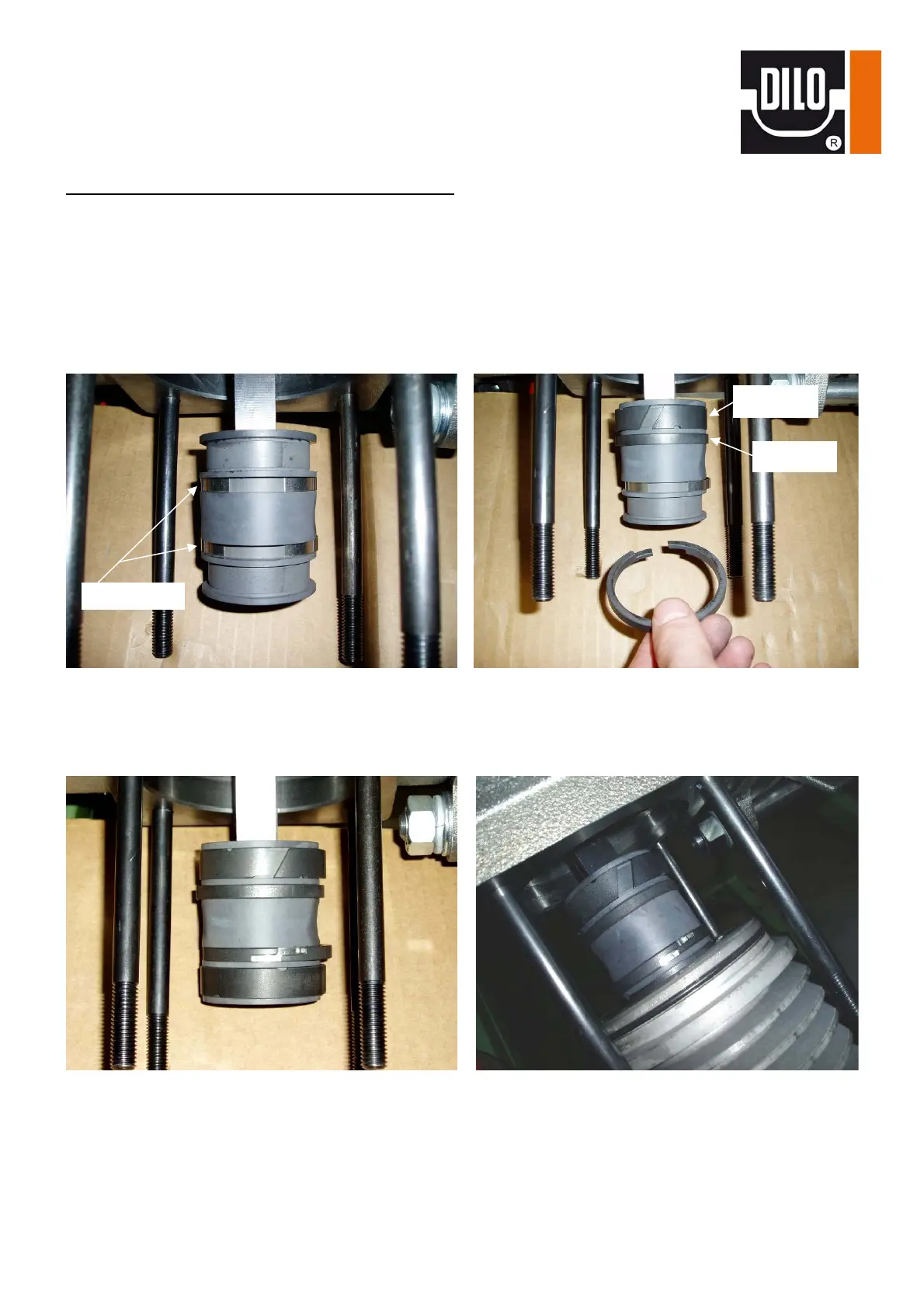

Assemble the cylinder.

Clean the valve seats or exchange them if necessary and put them on the cylinders.

Assemble the cylinder caps and hexagonal nuts and evenly thighten crosswise (35 Nm).

Assemble the complete tubing to the cylinder caps.

Carry out a leak test.

Assemble the cylinder covers.

tension spring

piston ring

guide ring

Loading...

Loading...