Suction pump | DSP 015

www.dilo-gmbh.com | C 3232-01 | Page 2 / 5

Cooling air direction check:

Put the palm of your hand on the cooling air openings of the cover in order to check if air is put out from

the fan.

In case of too low or none cooling air supply, check the electrical connection of the fan motor.

The cooling openings must be released.

Maintenance:

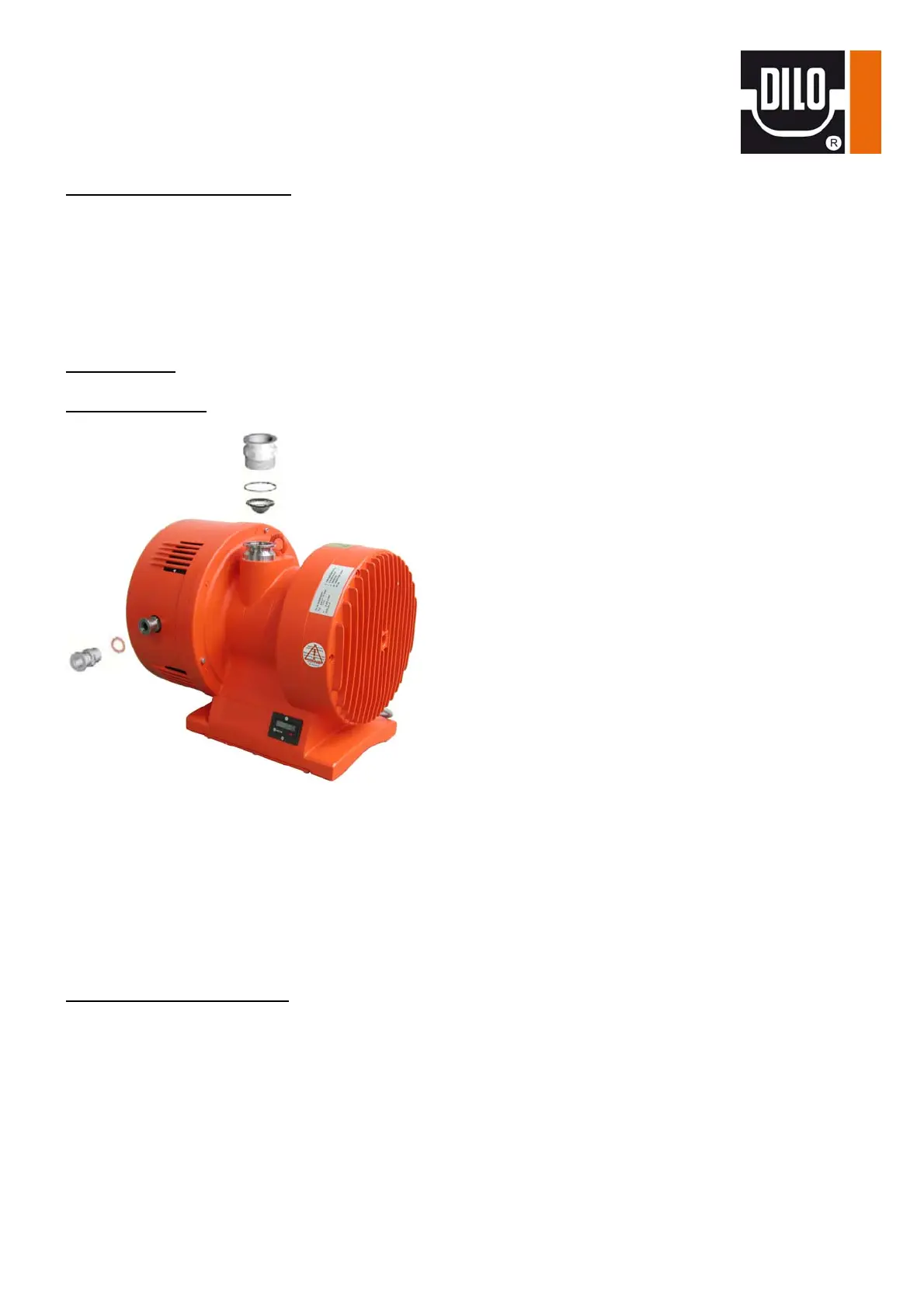

Cleaning of sieve

It is recommended to regularly check devices without particle filter connected in series for contamination.

Contaminated sieves could lower the suction capacity. Clean the sieve if necessary.

Unscrew the suction connection and remove the sieve.

Blow sieve with compressed air and reinstall the sieve with suction connection. Make sure that

the suction connection is clean and air tight.

Further maintenance works

We recommend carrying out maintenance works on the pump every 8000 operating hours. For this

purpose the pump is to be dismounted from the device. But recover the SF

6

-gas from the service cart

beforehand. Then dismount the pump.

When ordering the spare part kit for the pump (B105R58) you will receive detailed information on the

maintenance works.

Loading...

Loading...