- 25 -

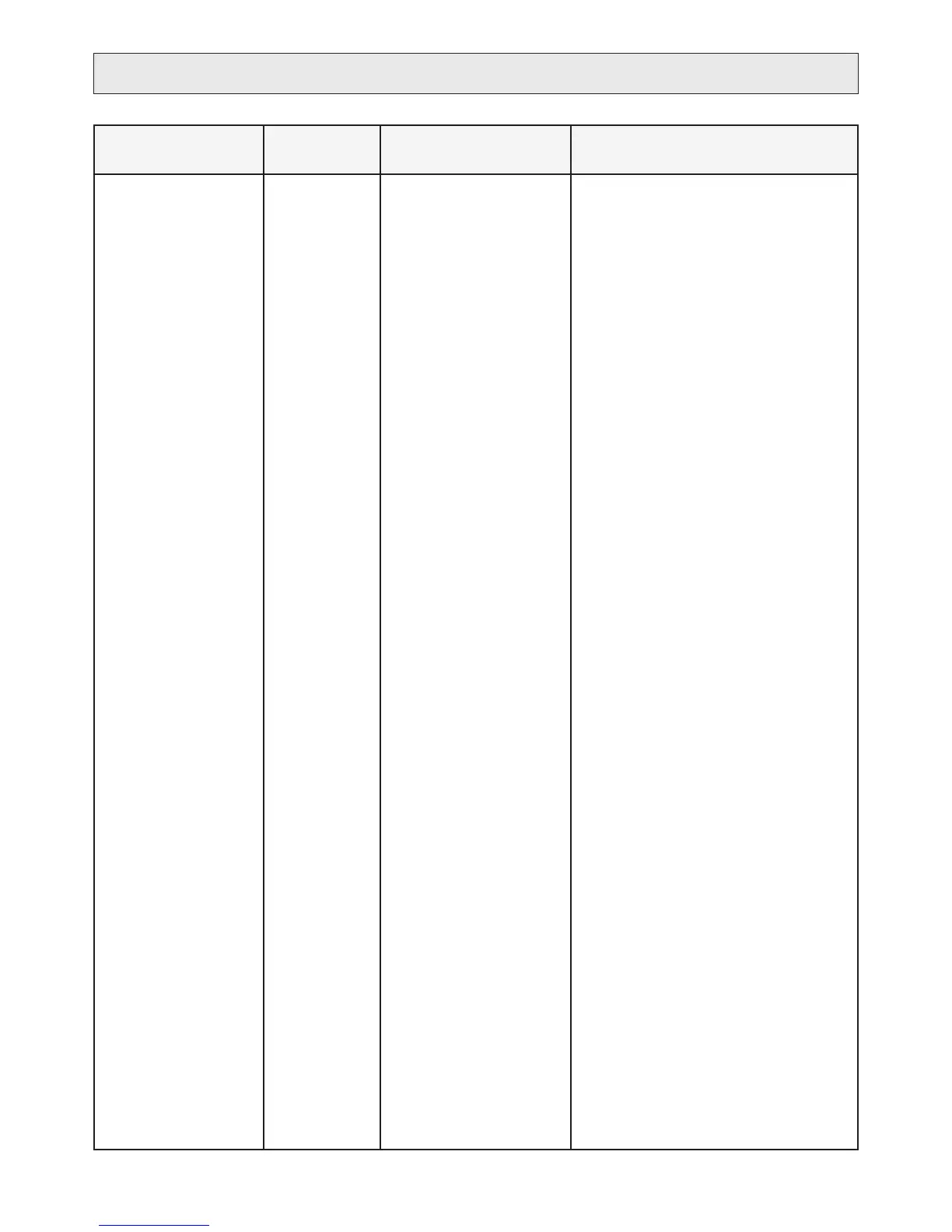

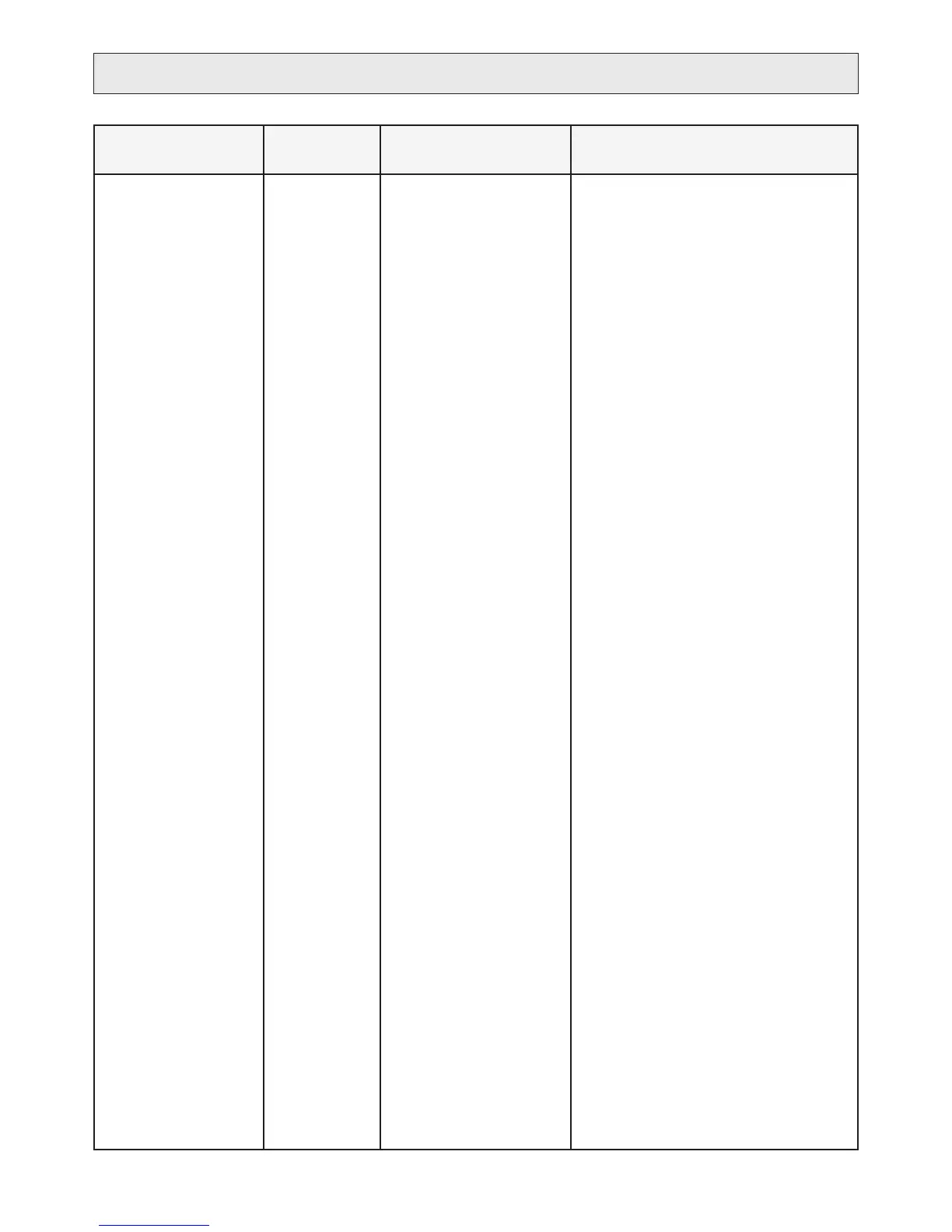

Symptom

Possible error

codes

Check/Action Remedy

Alarm, too low pres-

sure due to a high

pressure drop in the

lters.

Alarm, too low

pressure due to

too low feed pres-

sure.

12

Has lter I been replaced?•

Can a high particle load be •

expected?

Is the coarse lter clogged?•

Check valves for inlet water •

before the water purier is

opened.

Measure the dynamic feed •

pressure using the special

service tool.

Is the water temperature •

high, thus resulting in a very

high capacity of pure water

production?

Is there reason to believe •

that the feed pressure varies

a lot?

Are there other users at the •

net that occasionally might

draw large amounts of

water?

Are there other lters, •

valves etc. installed prior to

the water purier that can

reduce pressure?

If lter I has not been changed or if the parti-

cle load is high, change lter I and try again.

If lter I has been replaced but the problem re-

mains, remove lter II. If this solves the issue,

install a new lter II. (It can also be concluded

that the inlet pressure sensor is OK).

Clean the coarse lter.

Booster pump

If the water pressure is frequently low, a

booster pump is a solution. Make sure that

lters, installed prior to the water purier, do

not add to the pressure drop.

Reduced pure water ow

A very high pure water ow will increase the

requirements of high enough feed pressure.

Therefore, it is possible to reduce the pure

water ow by an external valve. (It should not

be restricted too much if a accumulator tank is

used since this will result in on/off operation.)

Reduced working pressure

Reduce the working pressure by manipulat-

ing the pressure regulating valve. A decreased

working pressure will reduce the water ow.

The drawback is that there is no “pressure”

buffer. If, for example, feed water temperature

is reduced or if the membrane is scaled, the

ow will immediately go down. Normally, this

would result in an increased working pressure

and maintained capacity.

Accumulation of water

If the problem is due to an almost complete

absence of water, consider (for a short period

of time) using an accumulator tank - pres-

surised with a check valve or open tank

combined with a pump - that can provide the

product with water.

External low pressure shut-down

Use an external inlet pressure sensor at the

inlet side combined with a valve on the pure

water side that cuts the pure water ow when

the feed pressure is too low.

Temporary disconnection

As a drastic measure consider temporarily dis-

connecting the water purier at periods when

the water pressure is low. This will reset the

low pressure alarm. Note that if this is made to

frequently, the pump may be damaged.

TROUBLESHOOTING

c)

d)

Loading...

Loading...