- 28 -

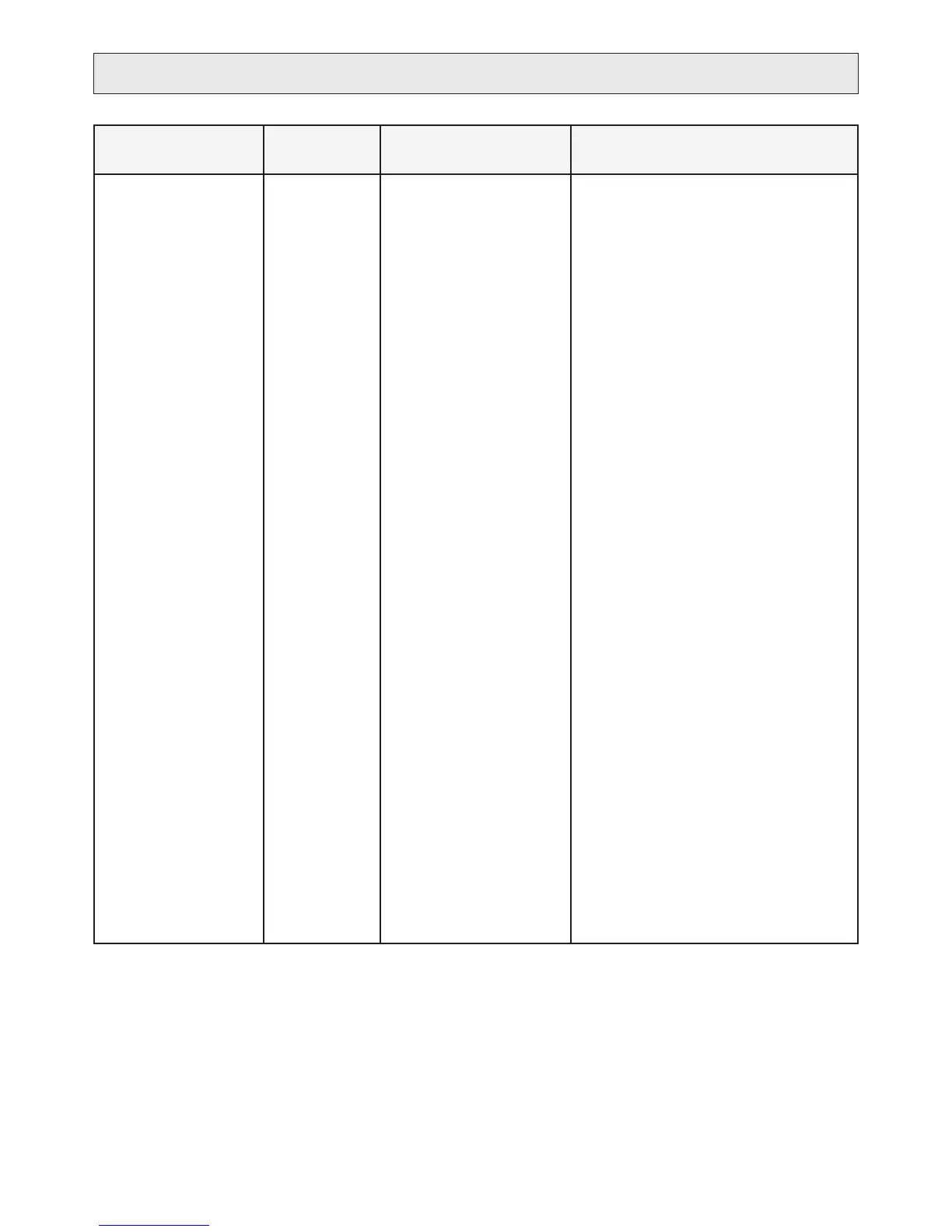

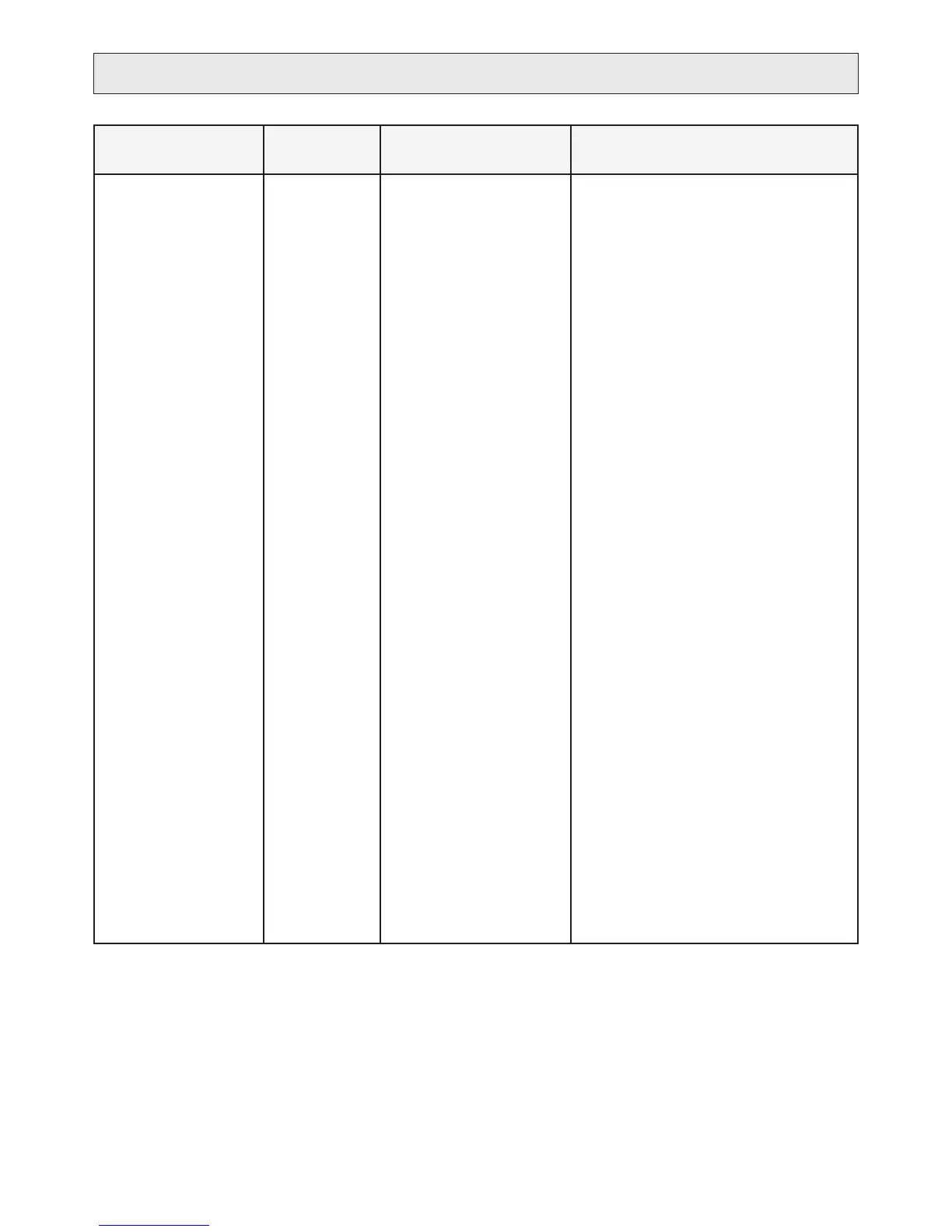

Symptom

Possible error

codes

Check/Action Remedy

The measured

conductivity indicates

a problem with the

purication.

Flushing does not

work properly. Bro-

ken reject valve.

17

Low pump pres-

sure.

18

Broken membrane.

Poor recirculation

ow.

19

Disconnect and connect •

the water purier. Flushing

starts and allows cold water

to enter the product.

Verify that the:

ushing commence after -

the tap/valve is closed,

reject ow is normal, and -

reject valve is energized. -

Measure the pump •

pressure.

Measure the conductivity in •

the inlet and the pure water.

Measure the conductivity of •

the pure water continuously

(several minutes).

If conductivity increases •

continuously after start

of pure water production,

check that:

The bottom of the mem- -

brane is not blocked due to

fouling, particles etc.

The membrane tape has -

not been unwinded (as-

sembly has to be dis-

mounted).

The reject ow is:

3 l/min — RO600C x

2 l/min — RO400B, RO400BC and RO400C x

0.8 l/min — RO400. x

Replace the reject valve if the reject ow is

> 5 l/min or much lower than the values given

above.

If the reject valve is not energized, check the

connections. Install a new PCB to see if that

solves the problem.

If the pump pressure and the water ow is low

in addition to a poor water quality - change the

pump, see “SERVICE”.

If the ow is OK and the water quality poor

from the start and it does not improve - change

the membrane, see “SERVICE”.

TROUBLESHOOTING

f)

e)

c)

d)

Loading...

Loading...