Vehicle System System Operation 28

Steering Gear

Steering Gear

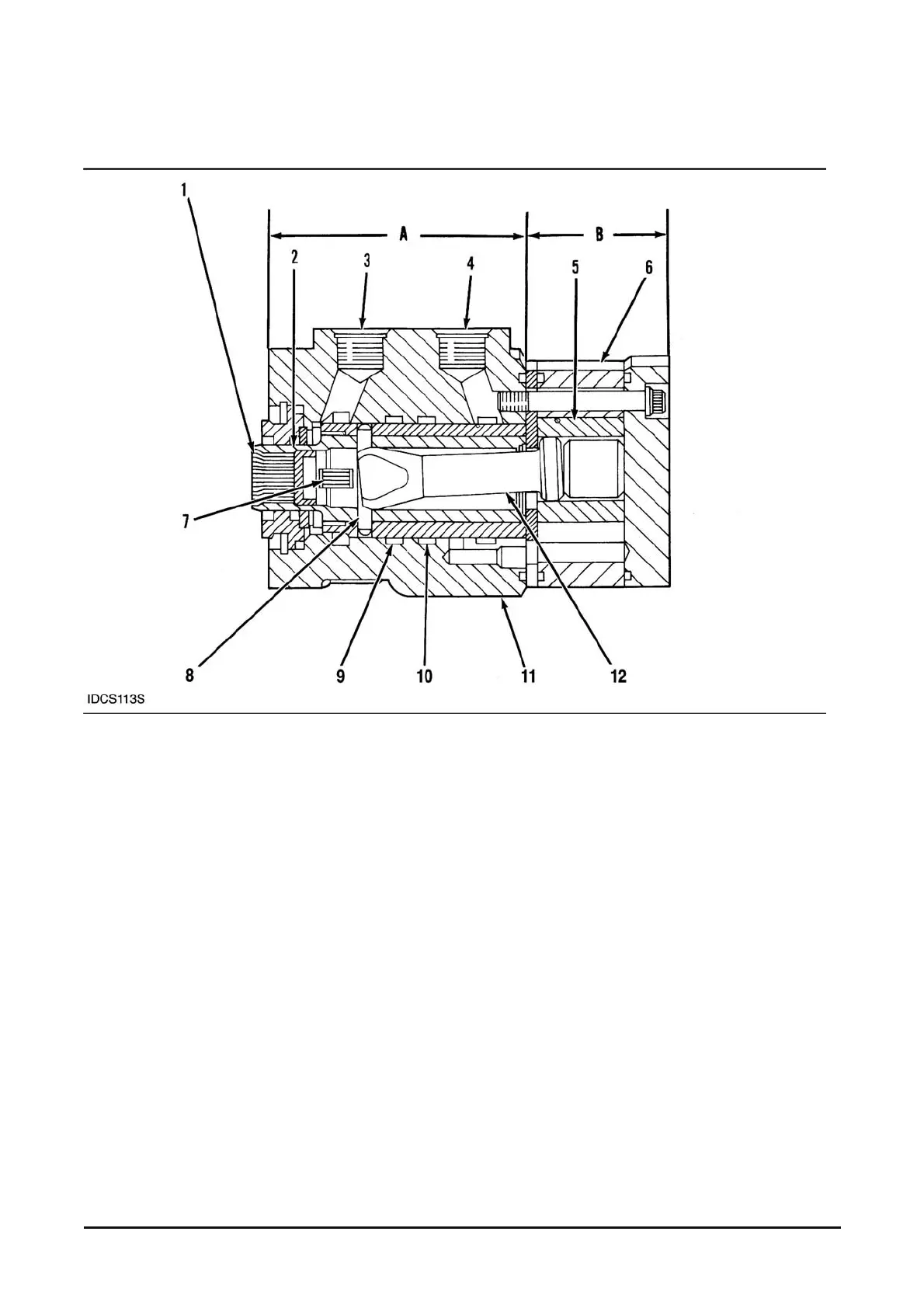

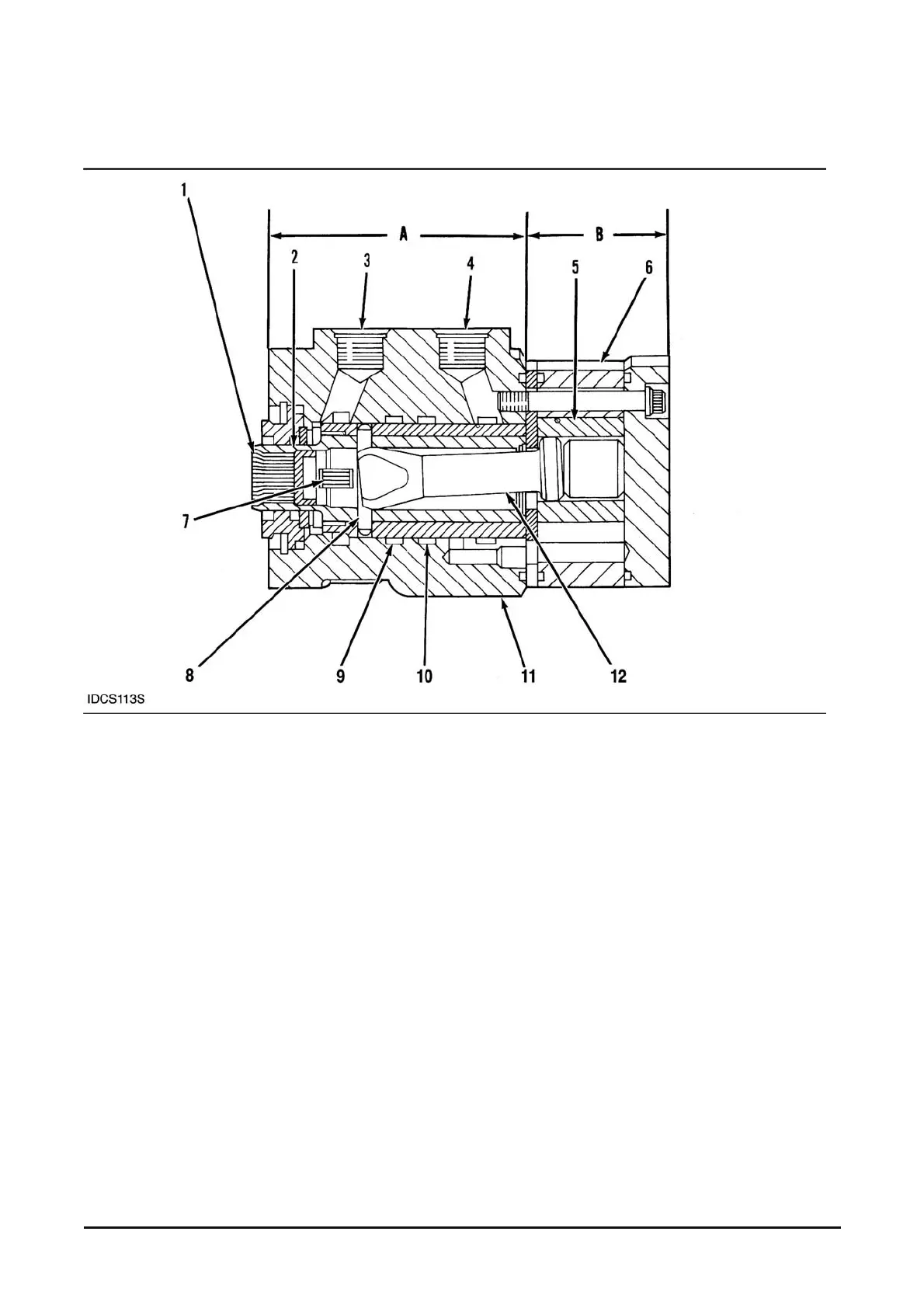

(1) Spool. (2) Sleeve. (3) Outlet (to tank). (4) Inlet (for pump oil). (5) Internal pump gear. (6) External pump gear. (7) Centering springs. (8)

Pin. (9) Left turn port. (10) Right turn port. (11) Body. (12) Drive. (A) Control section. (B) Metering section.

Lift trucks use the non load sensing, open center (oil

flow to steering gear only when needed) steering

gear.

All lift truck hydraulic lines serve a dual purpose in

that they serve both the steering and cylinder

hydraulics through the use of a priority valve. The

priority valve sends oil to the steering gear before

the needs of the cylinder hydraulics are met.

The steering gear has two main sections: control

section (A), and pump or metering section (B).

These two sections work together to send oil to the

steering cylinder.

Oil from the priority valve goes through inlet (4) into

the control section of the steering gear. When the

steering wheel is turned, the control section sends

the oil to and from the metering section and also to

and from the steering cylinder.

The metering section is a small hydraulic pump. It

controls (meters) the oil that goes to the steering

cylinder. As the steering wheel is turned faster, there

is an increase in the flow of oil to the steering

cylinder. This increased flow causes the main valves

pool to move farther. As the spool moves farther,

more oil can flow from the priority valve or power

steering pump to the steering cylinder, and a faster

turn is made.

Loading...

Loading...