Vehicle System System Operation 31

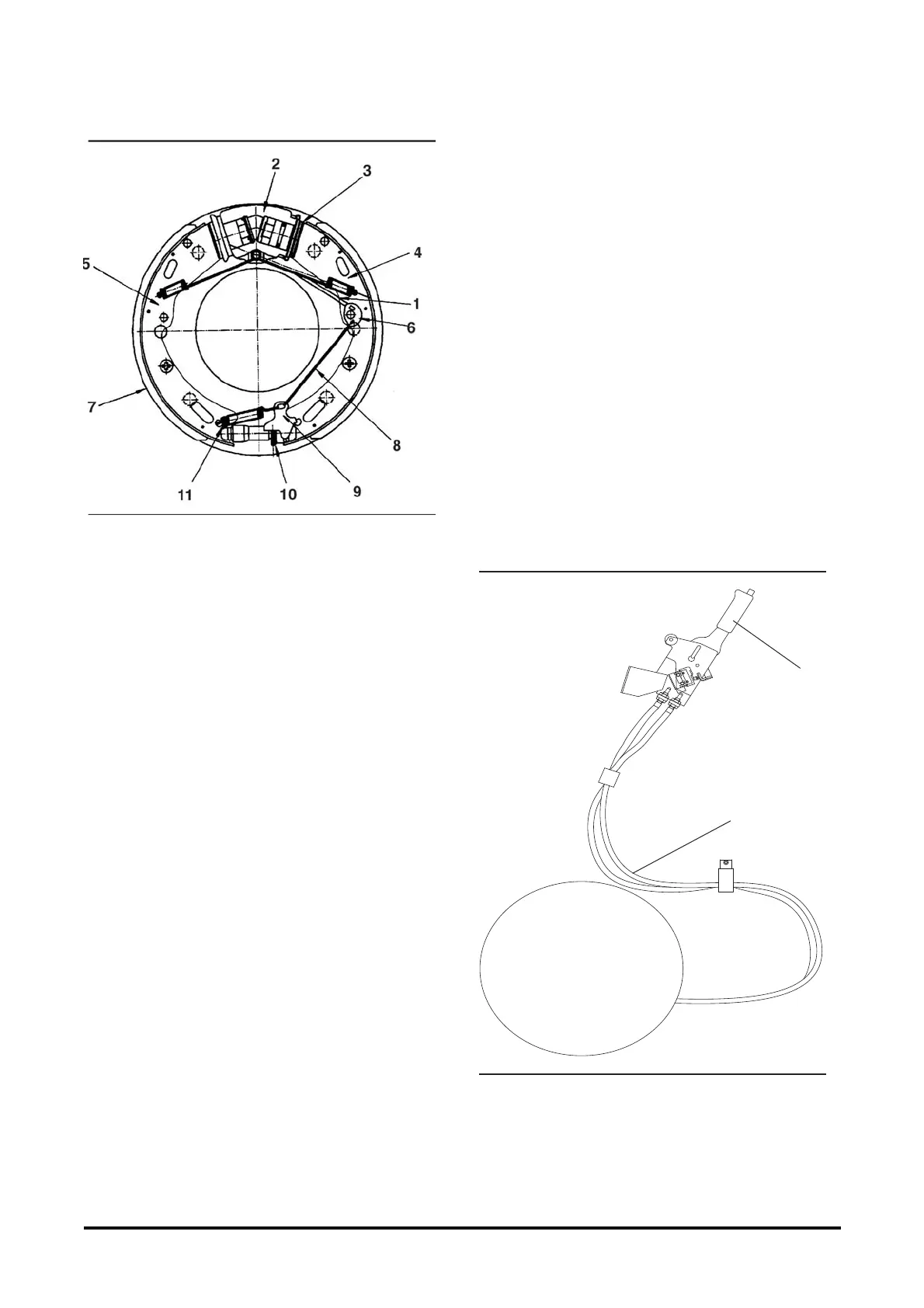

Shoe Type Brake

Brake with Automatic Adjustment (Right Side Shown)

(1) Upper adjustment link. (2) Cylinder assembly. (3) Piston.

(4) Secondary shoe. (5) Primary shoe. (6) Toggle lever. (7)

Support plate. (8) Lower adjustment link. (9) Adjustment lever.

(10) Adjustment screw. (11) Adjustment spring.

When the brake pedal is pushed down, the master

cylinder sends brake fluid to wheel cylinder (2).

Wheel cylinder pistons (3) are pushed out and move

primary shoe (5) and secondary shoe (4). The brake

shoes move until they make contact with the brake

drum.

When the brake action first starts, primary shoe (5)

comes in contact with the brake drum as it is in

rotation. This contact of the primary shoe puts some

force on secondary shoe (4) to help put it in position

against the drum.

Automatic Adjustment

Brakes with automatic adjustment are adjusted on

the reverse braking action. In this example the drum

rotation is counterclockwise (in reverse) which

causes a counterclockwise rotation of the brake

shoes.

Secondary shoe (4) moves away from cylinder (2)

that causes link (1) to move toggle lever (6) in a

clockwise rotation. Link (8) is connected to the lower

part of toggle lever (6) and to adjustment lever (9).

By this connection, adjustment lever (9) is moved in

a counterclockwise rotation.

When the brakes are released at the end of a

reverse brake application, adjustment spring (11)

puts adjustment lever (9) into its original position. If

the brake shoe lining has worn enough to let lever

(9) engaged, lever (9) will rotate screw (10) to put

the brake into the correct adjustment.

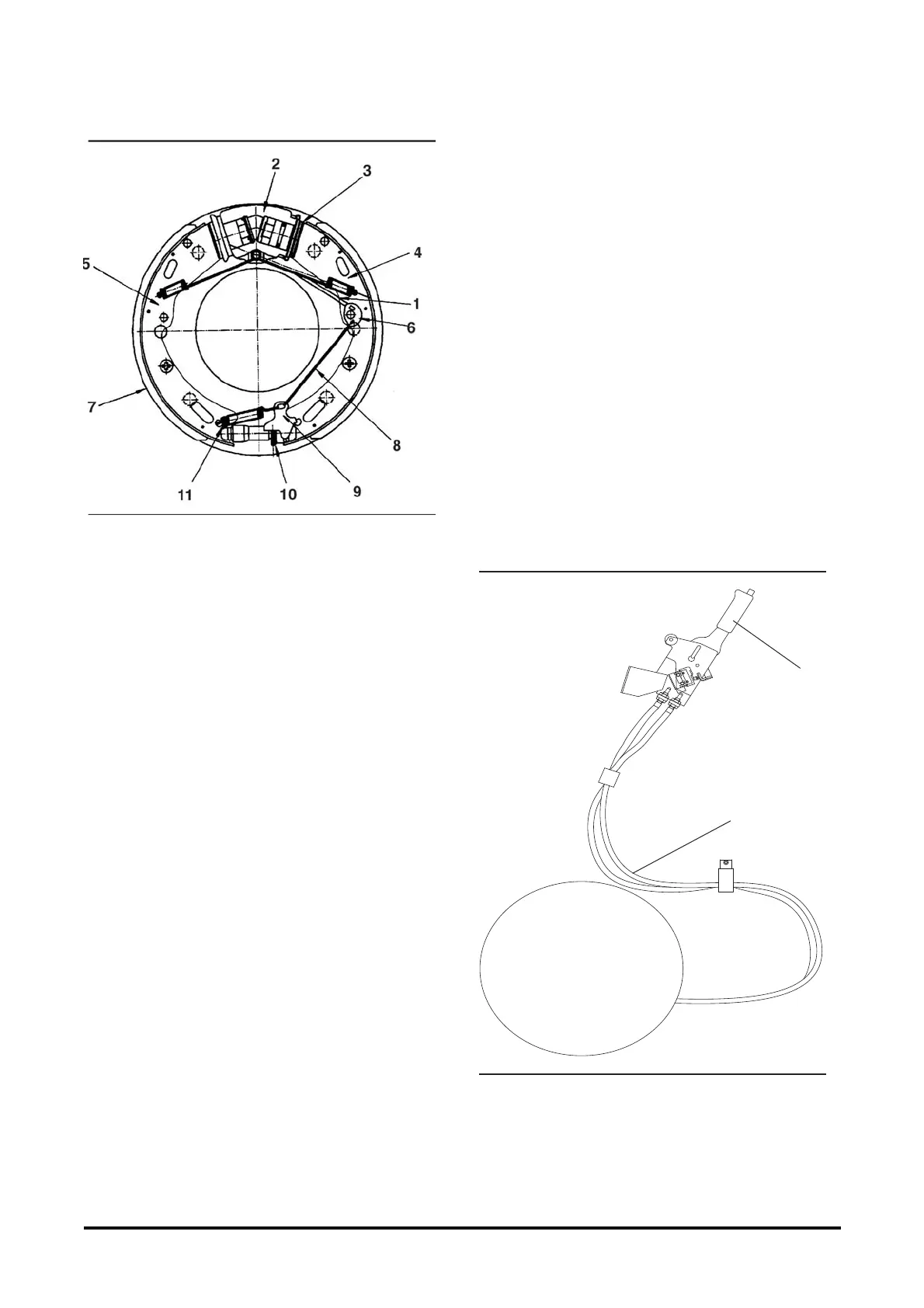

Parking Brake

Parking brakes use the shoe brake system

described above. The brakes are activated

mechanically instead of the hydraulic function. The

brakes are designed to hold the truck positively for

sure of parking by using parking lever (1) and cables

(2).

2

1

Loading...

Loading...