Vehicle System Testing and Adjusting 65

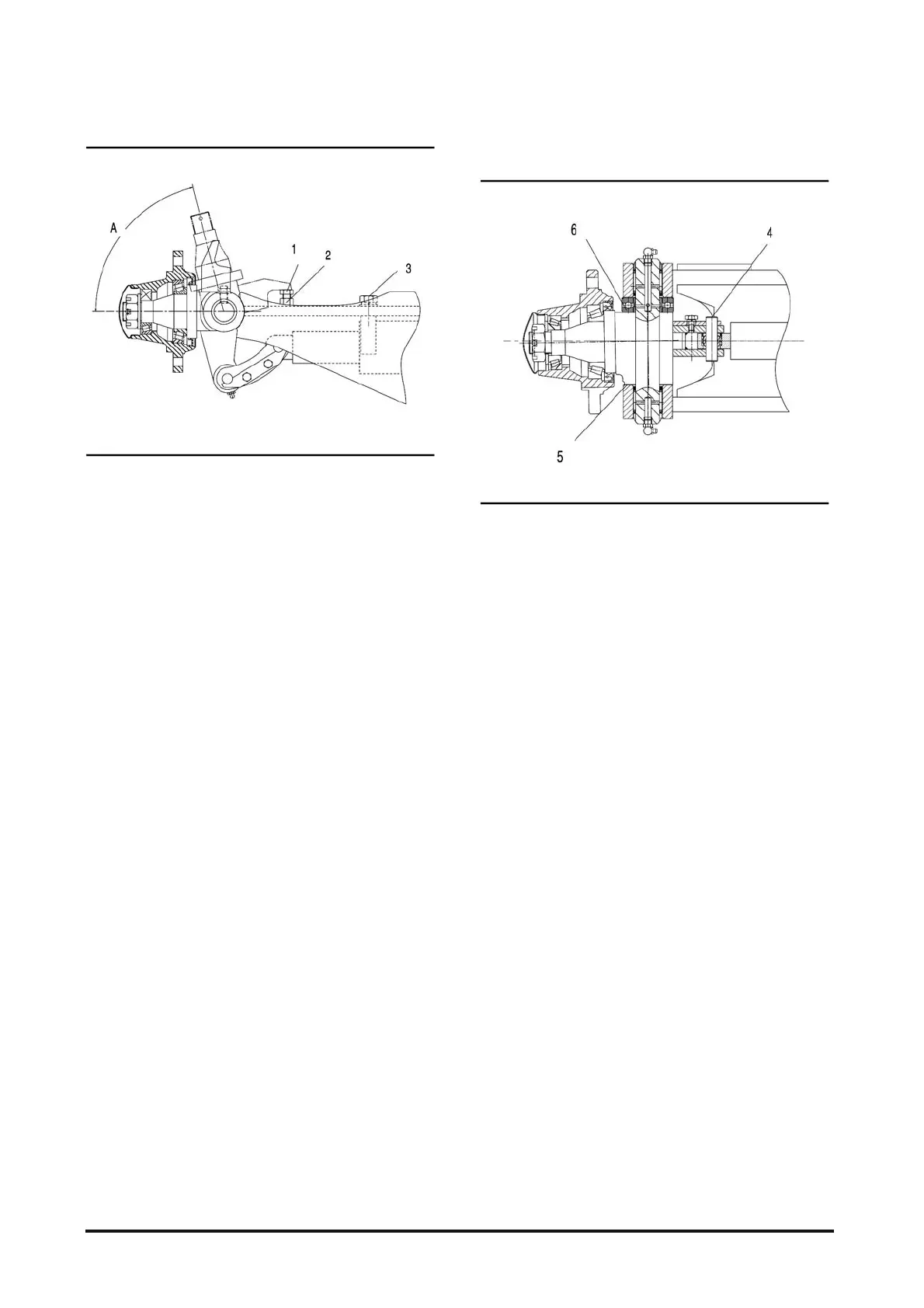

Steering Axle Stop Adjustment

Steer Angle

(1) Bolt. (2) Nut. (3) Bolt. (A) 76°angle.

Use the procedure that follows to make an

adjustment to the steer axle turning angle.

1. Adjust the cylinder rod extension so it is equal on

both sides of the axle.

2. Loosen nuts (2) on both sides of the steer axle.

3. Turn the steer wheel one direction until the steer

cylinder rod extension measures 97.5 mm (3.8 in)

than the straight ahead measurement.

4. Adjust stop bolt (1) on both sides.

5. Tighten nut (2) on both sides. Turn the steer

wheel the opposite direction and do the same

procedure for the opposite stop bolts. This will

give a maximum cramp angle of 76°

.

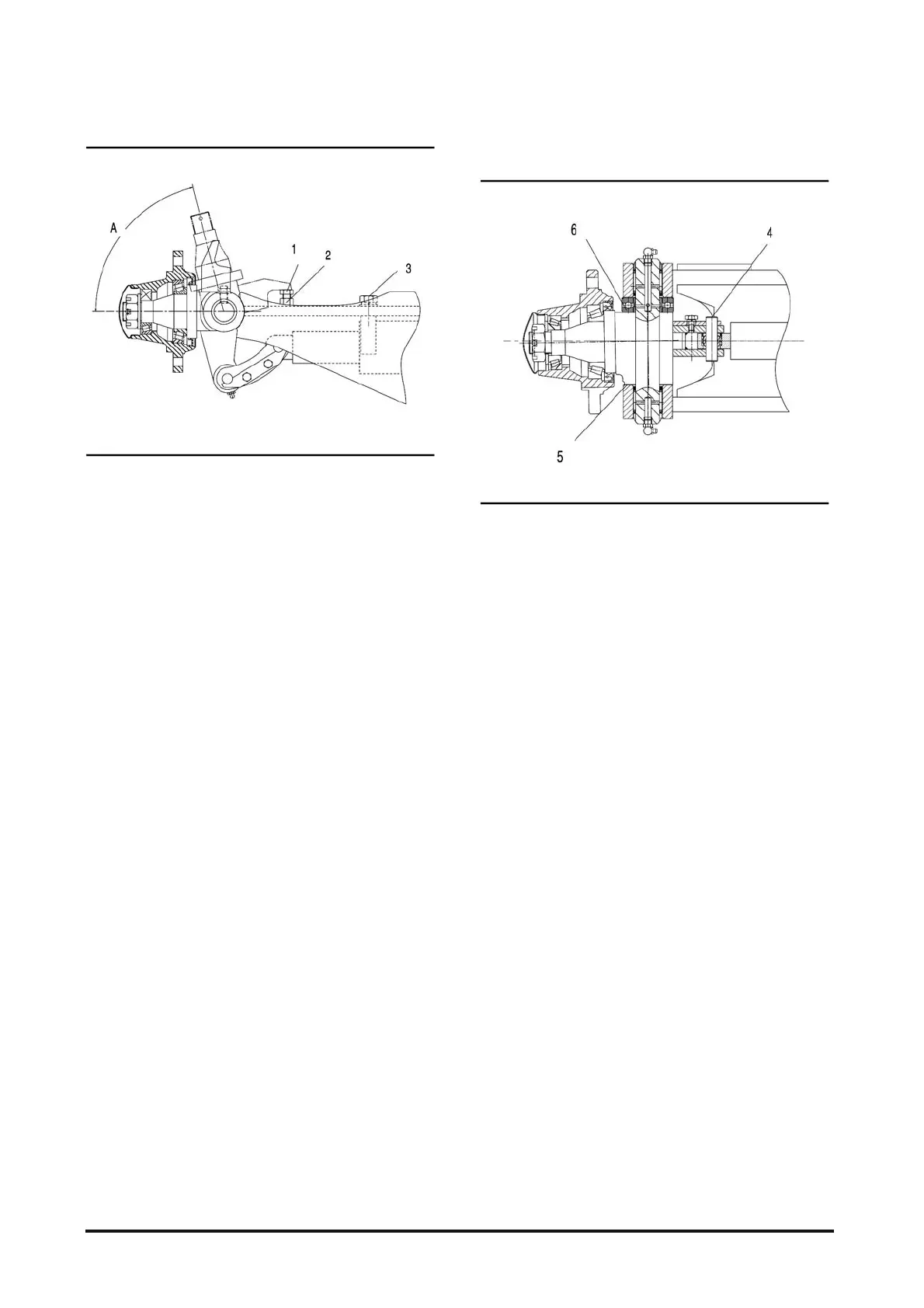

Steering Knuckle Bearing Preload

Adjustment

Steering Knuckle Bearing Preload Adjustment

(4) Steering link. (5) Shims. (6) Bearing.

1. During assembly of the steering knuckle, install

the thrust bearing and bushing without shims.

2. Measure the clearance between bearing (6) and

the axle beam.

3. Take an average of the measurements found in

Step 2. Select shims (5) equal in thickness to the

average clearance. For reference, the gad should

be less than 0.5 mm.

4. Remove the bearing group and install shims (5).

5. With steering links (4) disconnected from the

steering cylinder, check knuckle for 4.5 to 6.8 N·m

(40 to 60 lb·in) of rolling torque.

6. Connect links (4) to the steering cylinder.

Loading...

Loading...