Maintenance Section

-176-

Fuel Specifications

General Fuel Information

Use only fuel as recommended in this section.

NOTICE

Fill the fuel tank at the end of each day of operation

to drive out moisture laden air and to prevent

condensation. Maintain a constant level near the

top of the day tank to avoid drawing moisture into

the tank as the level decreases.

Do not fill the tank to the top. Fuel expands as it

gets warm and can overflow.

Do not fill the fuel filters with fuel before installing

them. Contaminated fuel will cause accelerated

wear to the fuel system parts.

Drain the water and sediment from main fuel

storage tank before it is refilled. This will help

prevent water and/or sediment from being pumped

from the fuel storage tank into the engine fuel tank.

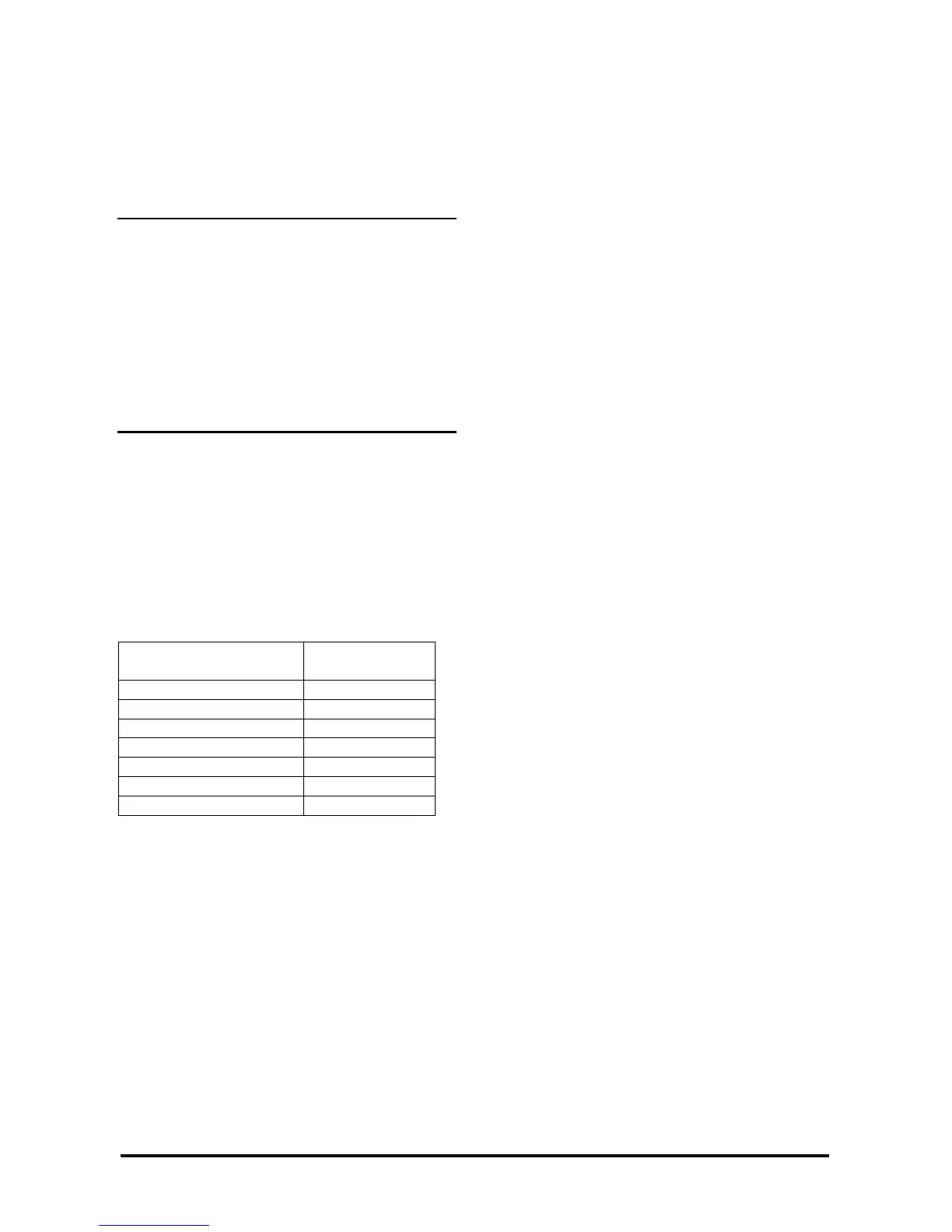

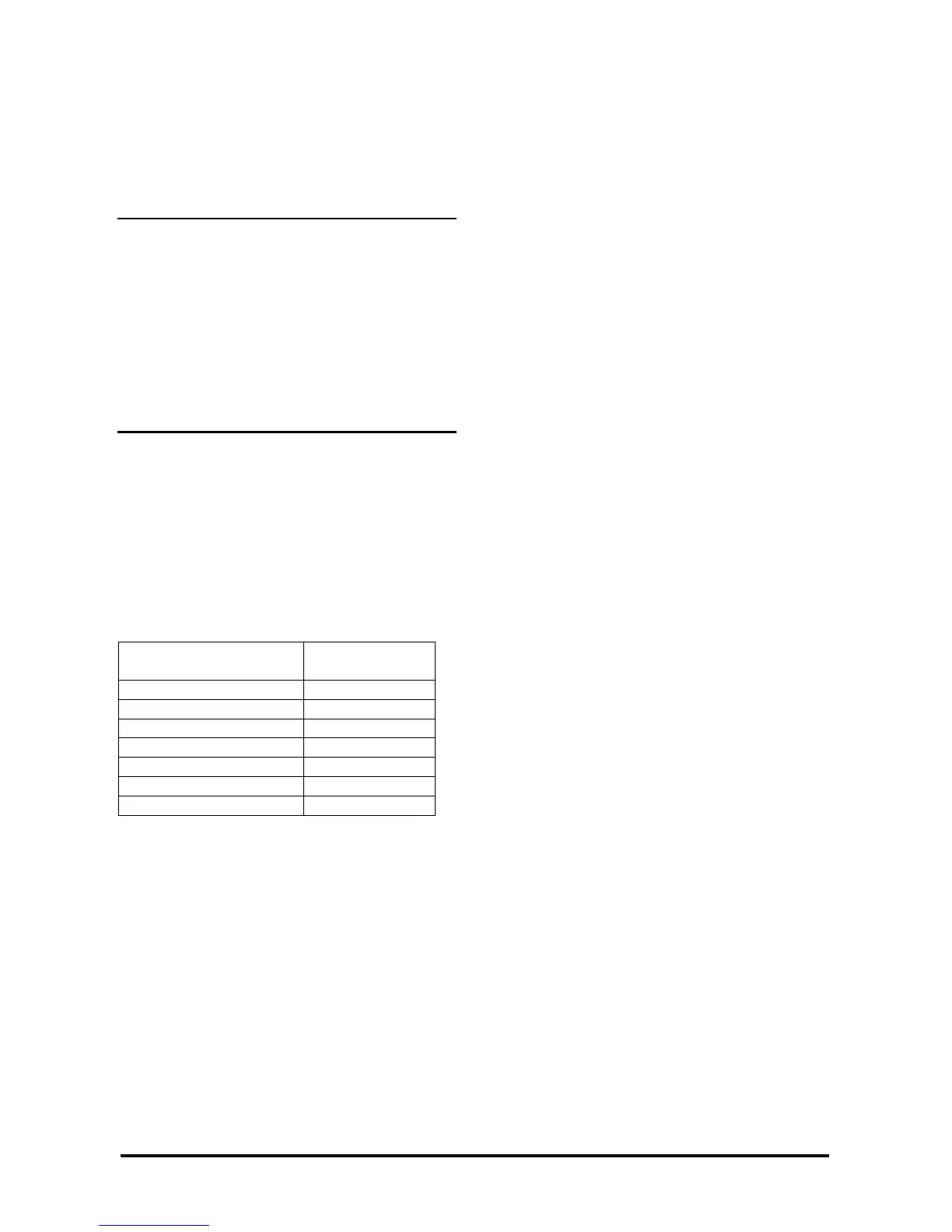

Diesel Fuel Specifications

Diesel fuel should comply with the following

specifications. The table lists several worldwide

specifications for diesel fuels.

Diesel Fuel

Specification

Location

ASTM D975 No.1D/2D USA

EN590:96 EU

IS0 8217 DMX International

BS 2869-A1 or A2 United Kingdom

JIS K2204 Grade No. 2 Japan

KSM-2610 Korea

GB252 China

Additional Technical Fuel Requirements

z The fuel cetane number should be equal to 45 or

higher.

z The sulfur content must not exceed 0.5% by

volume. Less than 0.05% is preferred.

z For electronically controlled engines, for example

4TNV98-ZSDF, it is mandatory to use fuel that

does not contain 0.1 % or more sulfur content.

z In general, using a high sulfur fuel may possible

result in corrosion inside the cylinder.

z Especially in U.S.A. and Canada, Low Sulfur

(300-500mglkg sulfur content) or Ultra Low Sulfur

fuel should be used.

z Bio-Diesel fuels. See Bio-Diesel Fuels on next

page.

z NEVER mix kerosene, used engine oil, or

residual fuels with the diesel fuel.

z The water and sediment in the fuel should not

exceed 0.05% by volume.

z Keep the fuel tank and fuel-handling equipment

clean at all times.

z Poor quality fuel can reduce engine performance

and / or cause engine damage.

z Fuel additives are not recommended. Some fuel

additives may cause poor engine performance.

z Consult your Doosan representative for more

information.

z The ash content must not exceed 0.01% by

volume.

z The carbon residue content must not exceed

0.35% by volume. Less than 0.1 % is preferred.

z The total aromatics content should not exceed

35% by volume. Less than 30% is preferred.

z The PAH (polycyclic aromatic hydrocarbons)

content should be below 10% by volume.

z The metal content of Na, Mg, Si, and Al should

be equal to or lower than 1 mass ppm.

z Lubricity: The wear mark of WS1.4 should be

Max. 0.01 8 in (460 pm) at HFRR test.

Bio-Diesel Fuels

In Europe and in the United States, as well as

some other countries, non-mineral oil based fuel

resources such as RME (Rapeseed Methyl Ester)

and SOME (Soybean Methyl Ester), collectively

known as FAME (Fatty Acid Methyl Esters), are

being used as extenders for mineral oil derived

diesel fuels.

Doosan approves the use of bio-diesel fuels that do

not exceed a blend of 5% (by volume) of FAME

with 95% (by volume) of approved mineral oil

derived diesel fuel. Such bio-diesel fuels are known

in the marketplace as B5 diesel fuels.

Loading...

Loading...