Maintenance Section

-229-

Inspect Mixer Assembly

(G420F(E)/G424F(E)/G424I(E)

/G430FE Engine Only)

Refer to the LP mixer section of the engine service

manual for procedures.

Inspect Throttle Assembly

(G420F(E)/G424F(E)/G424I(E)

/G430FE Engine Only)

1. Visually inspect the throttle assembly motor

housing for coking, cracks and missing

cover-retaining clips. Repair and/or replace as

necessary.

NOTE: Refer to the LP mixer and throttle section

of the service manual for procedures on

removing the mixer and inspecting the

throttle plate.

Engine Valve Lash (Diesel Engine

Only) - Check, Adjust

NOTICE

The valve clearances are to be adjusted at the

times of the following situations.

z When the engine is overhauled and the cylinder

heads are disassembled.

z When severe noise comes from valve train.

z When the engine is not normally operated even

though there is no trouble in the fuel system.

WARNING

To prevent possible injury when adjusting

diesel engines, do not use the starter motor to

turn the flywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before

measuring valve clearance.

NOTICE

Measure the valve lash with the engine stopped. To

obtain an accurate measurement, allow at least 20

minutes to cool the engine cylinder head and block

temperature.

Set the clearance to the nominal appropriate

clearance given in the “Valve Clearance Setting”

shown below.

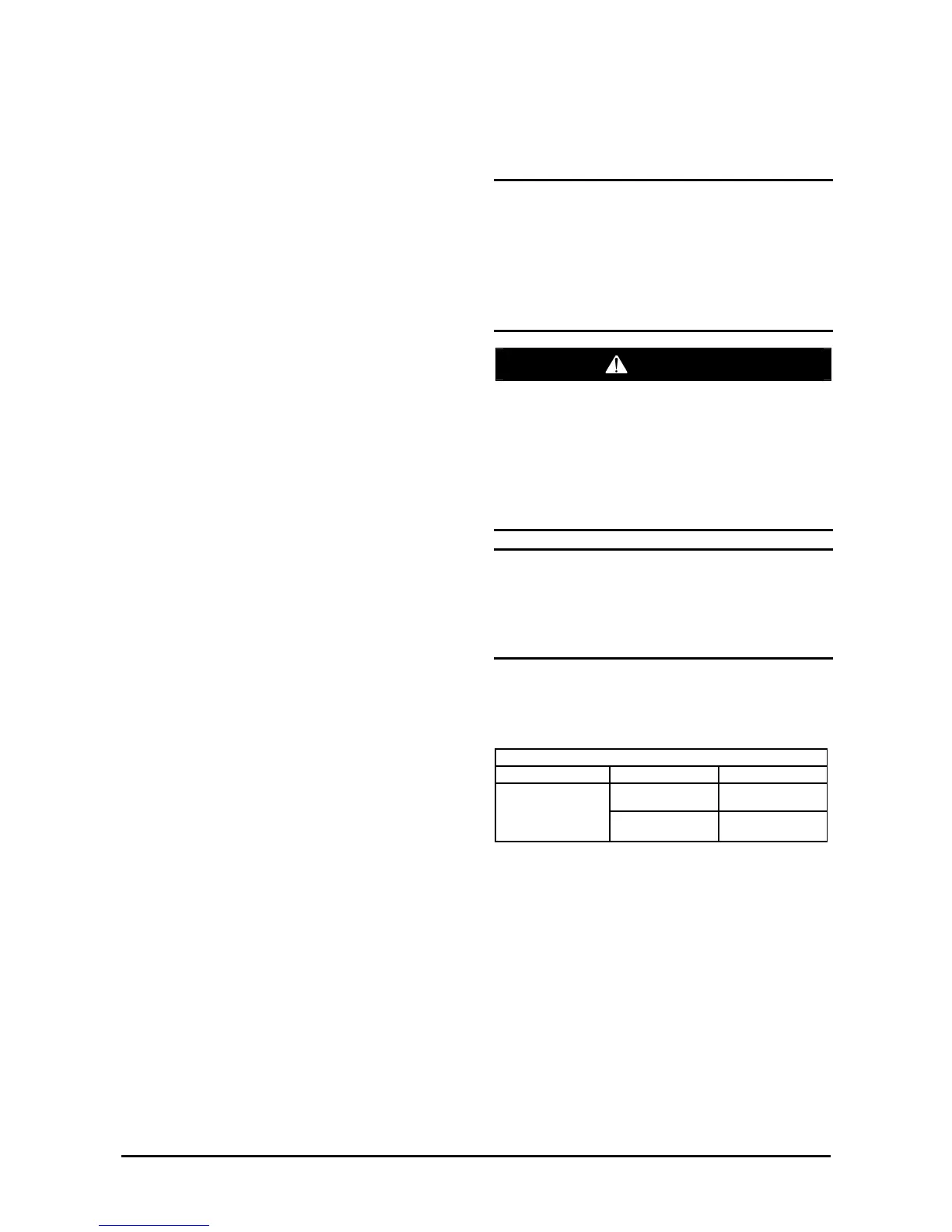

Valve Clearances

Engine Valve Clearance

3.3 liter

(4TNV98 &

4TNE98) Diesel

Exhaust Valves 0.2 mm (.0.08 in)

Intake Valves 0.2 mm (.0.08 in)

Refer to the “Service Manual” for the complete

valve adjustment procedure.

In regards to G420F(E) and G424F(E) Engines,

valve adjustment is not necessary because of

automatic adjusting system

Loading...

Loading...